Configuring the Inverter for Multiple Motors

Operations

and Monitoring

4–56

Configuring the Inverter for Multiple Motors

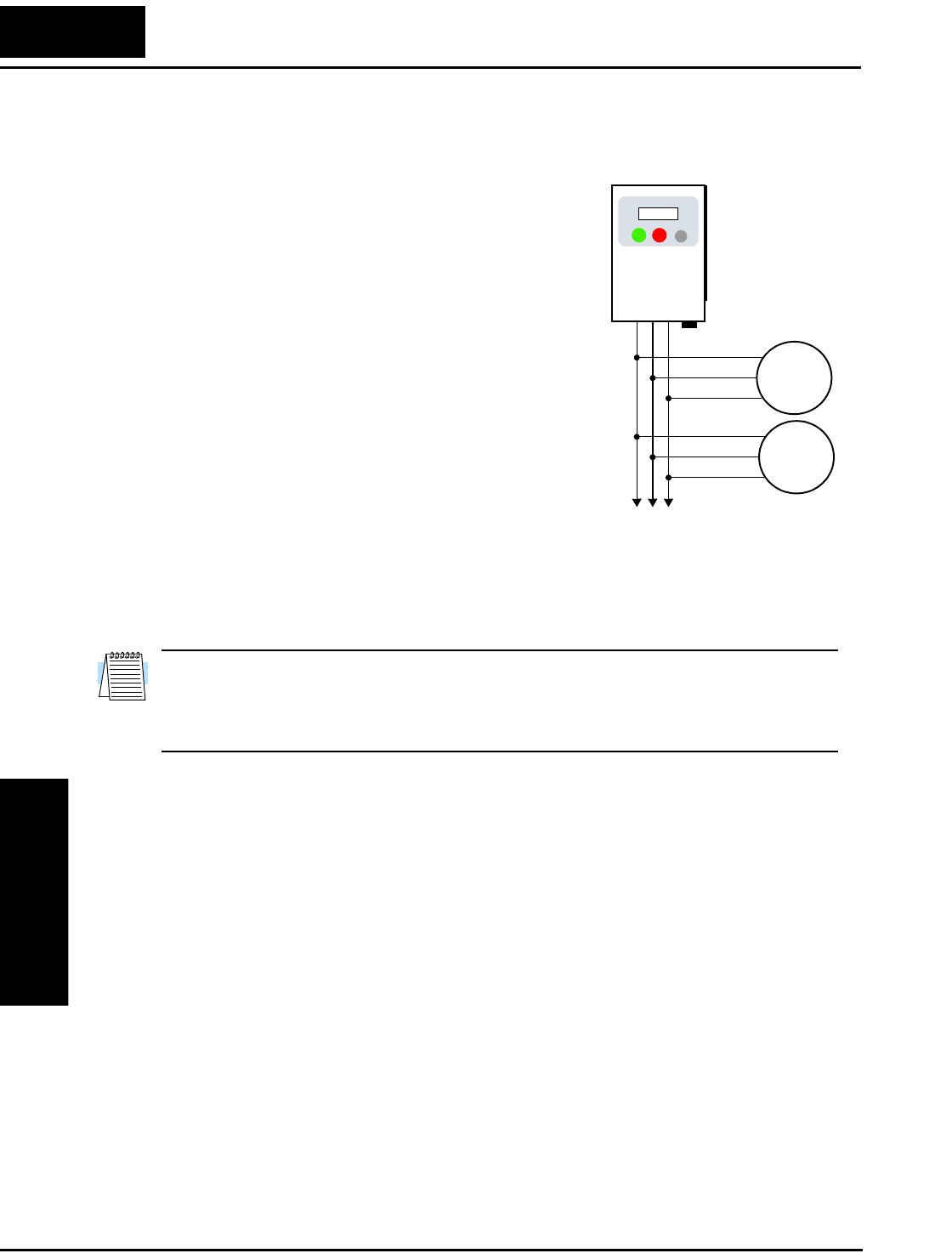

Simultaneous Connections

For some applications, you may need to connect two

or more motors (wired in parallel) to a single inverter’s

output. For example, this is common in conveyor

applications where two separate conveyors need to

have approximately the same speed. The use of two

motors may be less expensive than making the

mechanical link for one motor to drive multiple

conveyors.

Some of the characteristics of using multiple motors

with one drive are:

• The inverter output must be rated to handle the sum

of the currents from the motors.

• You must use separate thermal protection switches

or devices to protect each motor. Locate the device

for each motor inside the motor housing or as close

to it as possible.

• The wiring for the motors must be permanently connected in parallel (do not remove

one motor from the circuit during operation).

NOTE: The motor speeds are identical only in theory. That is because slight differences

in their loads will cause one motor to slip a little more than another, even if the motors

are identical. Therefore, do not use this technique for multi-axis machinery that must

maintain a fixed position reference between its axes.

Inverter Configuration for Two Motor Types

Some equipment manufacturers may have a single type of machine that has to support

two different motor types—and only one motor will be connected at a time. For

example, an OEM may sell basically the same machine to the US market and the

European market. Some reasons why the OEM needs two motor profiles are:

• The inverter power input voltage is different for these markets.

• The required motor type is also different for each destination.

In other cases, the inverter needs two profiles because the machine characteristics vary

according to these situations:

• Sometimes the motor load is very light and can move fast. Other times the motor load

is heavy and must move slower. Using two profiles allows the motor speed, accelera-

tion and deceleration to be optimal for the load and avoid inverter trip (fault) events.

• Sometimes the slower version of the machine does not have special braking options,

but a higher performance version does have braking features.

to Nth motor

U/T1

V/T2

W/T3

Motor 1

Motor 2

L200

U/T1

V/T2

W/T3