7. HG-SR SERIES

7 - 15

(3) Permissible loads of servo motor shaft

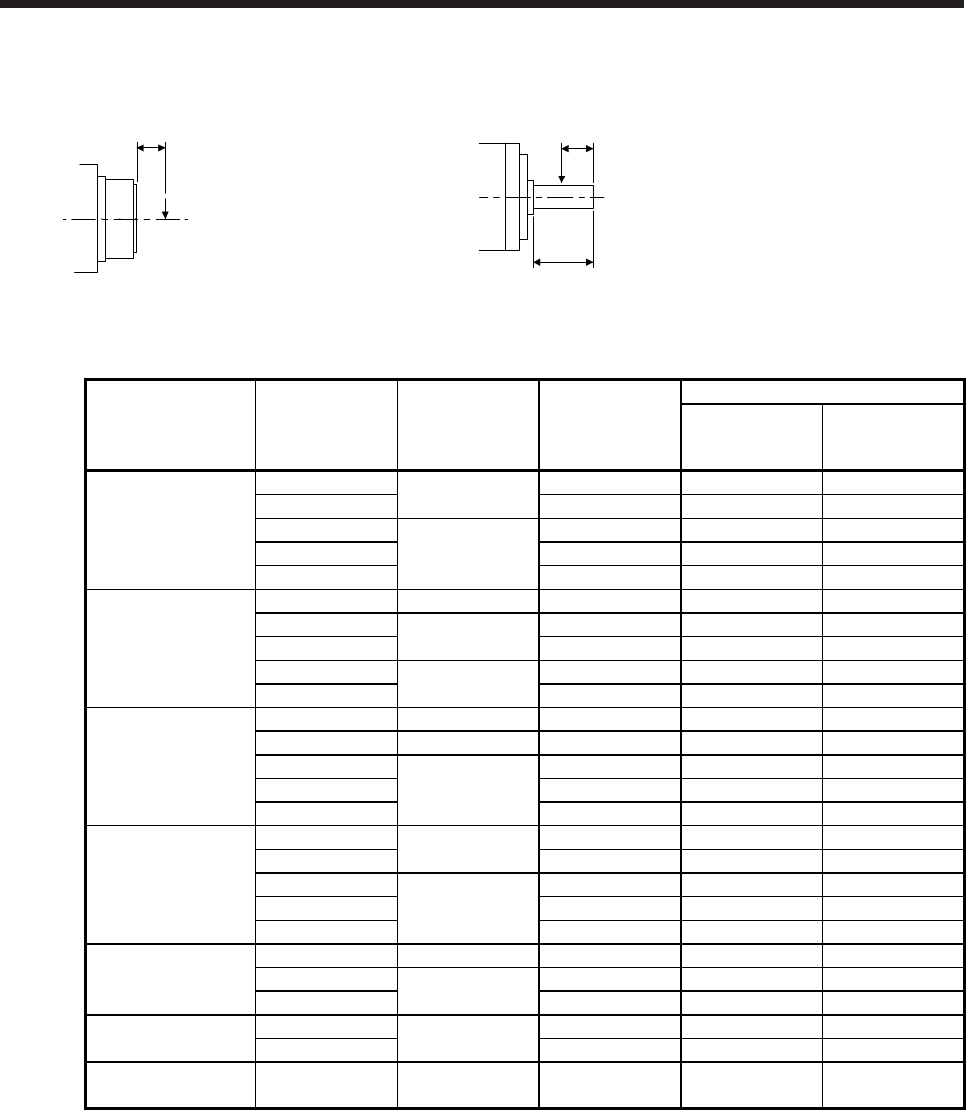

The radial load point of a high precision reducer is as shown below.

L: Distance between reducer

end face and load center

L

Q: Length of axis (Refer to section 7.7.9, 7.7.10.)

Q/2

Q

Flange-mounting flange output type for

high precision application (G5)

Flange-mounting shaft output type for

high precision application (G7)

Servo motor Reduction ratio

Reducer model

number

Radial load point

L [mm]

Permissible load (Note)

Permissible radial

load

[N]

Permissible thrust

load

[N]

HG-SR52(4)(B)G5

HG-SR52(4)(B)G7

1/5

20A

32 416 1465

1/11 32 527 1856

1/21

32A

57 1094 4359

1/33 57 1252 4992

1/45 57 1374 5478

HG-SR102(4)(B)G5

HG-SR102(4)(B)G7

1/5 20A 32 416 1465

1/11

32A

57 901 3590

1/21 57 1094 4359

1/33

50A

62 2929 10130

1/45 62 3215 11117

HG-SR152(4)(B)G5

HG-SR152(4)(B)G7

1/5 20A 32 416 1465

1/11 32A 57 901 3590

1/21

50A

62 2558 8845

1/33 62 2929 10130

1/45 62 3215 11117

HG-SR202(4)(B)G5

HG-SR202(4)(B)G7

1/5

32A

57 711 2834

1/11 57 901 3590

1/21

50A

62 2558 8845

1/33 62 2929 10130

1/45 62 3215 11117

HG-SR352(4)(B)G5

HG-SR352(4)(B)G7

1/5 32A 57 711 2834

1/11

50A

62 2107 7285

1/21 62 2558 8845

HG-SR502(4)(B)G5

HG-SR502(4)(B)G7

1/5

50A

62 1663 5751

1/11 62 2107 7285

HG-SR702(4)(B)G5

HG-SR702(4)(B)G7

1/5 50A 62 1663 5751

Note. Do not subject the shaft to load greater than the value.

The value in the table assumes that the load is applied independently.