2. INSTALLATION

2 - 4

2.4 Permissible load for the shaft

CAUTION

Do not use a rigid coupling as it may apply excessive bending load to the shaft of

the servo motor, leading the shaft to break and the bearing to wear out.

For the permissible shaft load specific to the servo motor, refer to the chapter of the servo motor series.

(1) Use a flexible coupling and adjust the misalignment of the shaft to less than the permissible radial load.

(2) When using a pulley, sprocket or timing belt, select a diameter that will fit into the permissible radial load.

(3) Excess of the permissible load can cause the bearing life to reduce and the shaft to break.

(4) The load indicated in this section is static load in a single direction and does not include eccentric load.

Make eccentric load as small as possible. Not doing so can cause the servo motor to be damaged.

2.5 Protection from oil and water

Provide adequate protection to prevent foreign matter, such as oil from entering the servo motor shaft. When

installing the servo motor, consider the items in this section.

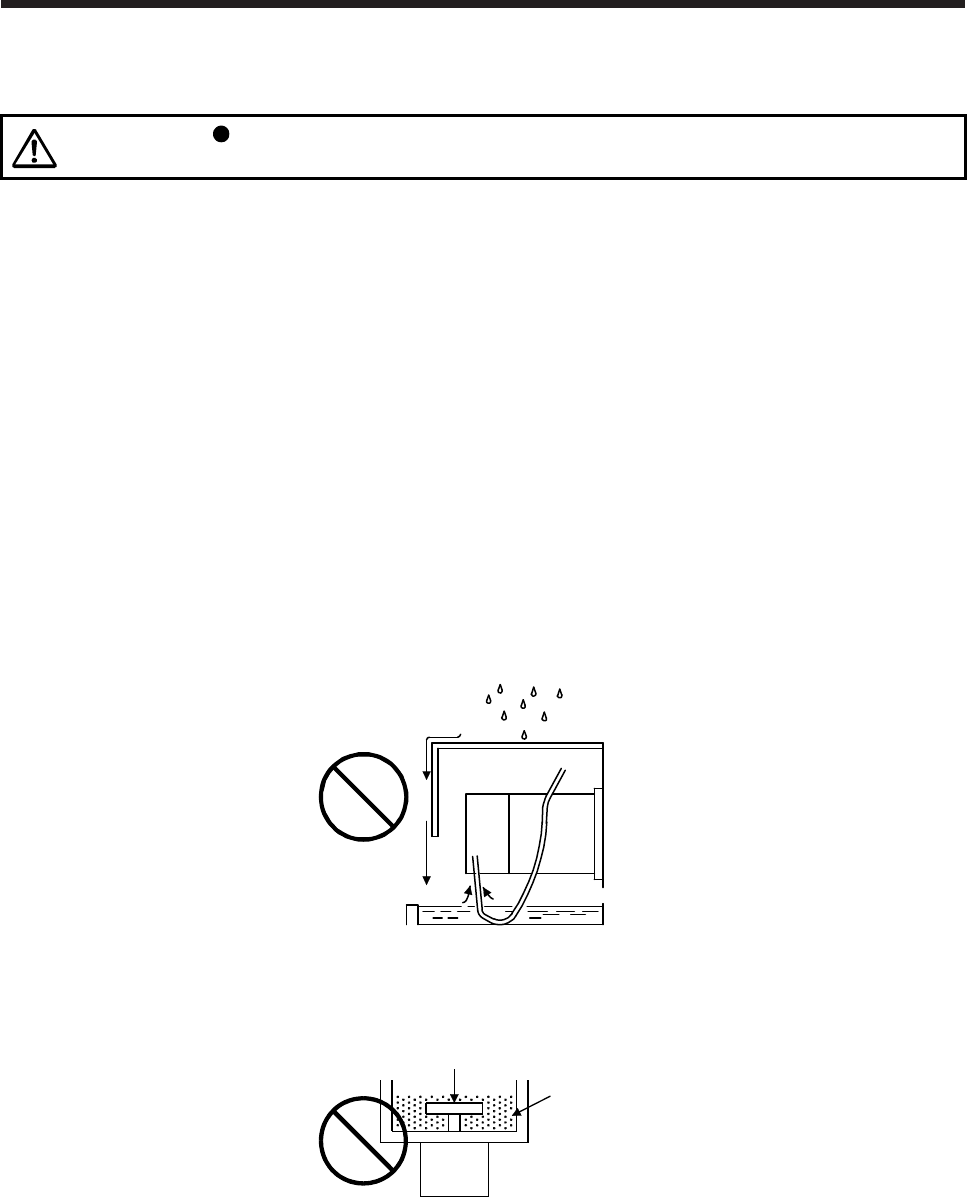

(1) Do not use the servo motor with its cable soaked in oil or water.

Cover

Capillary action

Oil/water pool

Servo

motor

(2) When the servo motor is to be installed with the shaft end at top, provide measures so that it is not

exposed to oil and water entering from the machine side, gear box, etc.

Gear

Lubricating oil

Servo motor

(3) If oil such as cutting oil drops on the servo motor, the sealant, packing, cable and others may be affected

depending on the oil type.

(4) In the environment where the servo motor is exposed to oil mist, oil, water, grease and/or like, a

standard specifications servo motor may not be usable. Please contact your local sales office.