2. INSTALLATION

2 - 5

2.6 Cable

The power supply and encoder cables routed from the servo motor should be fixed to the servo motor to

keep them unmovable. Otherwise, the cable may disconnect. In addition, do not modify the connectors,

terminals and others at the ends of the cables.

2.7 Servo motor with oil seal

For the servo motor with oil seal, the oil seal prevents the entry of oil into the servo motor. Make sure to

install it according in this section.

The functions have no problem even if the servo motor with oil seal may sound during operation.

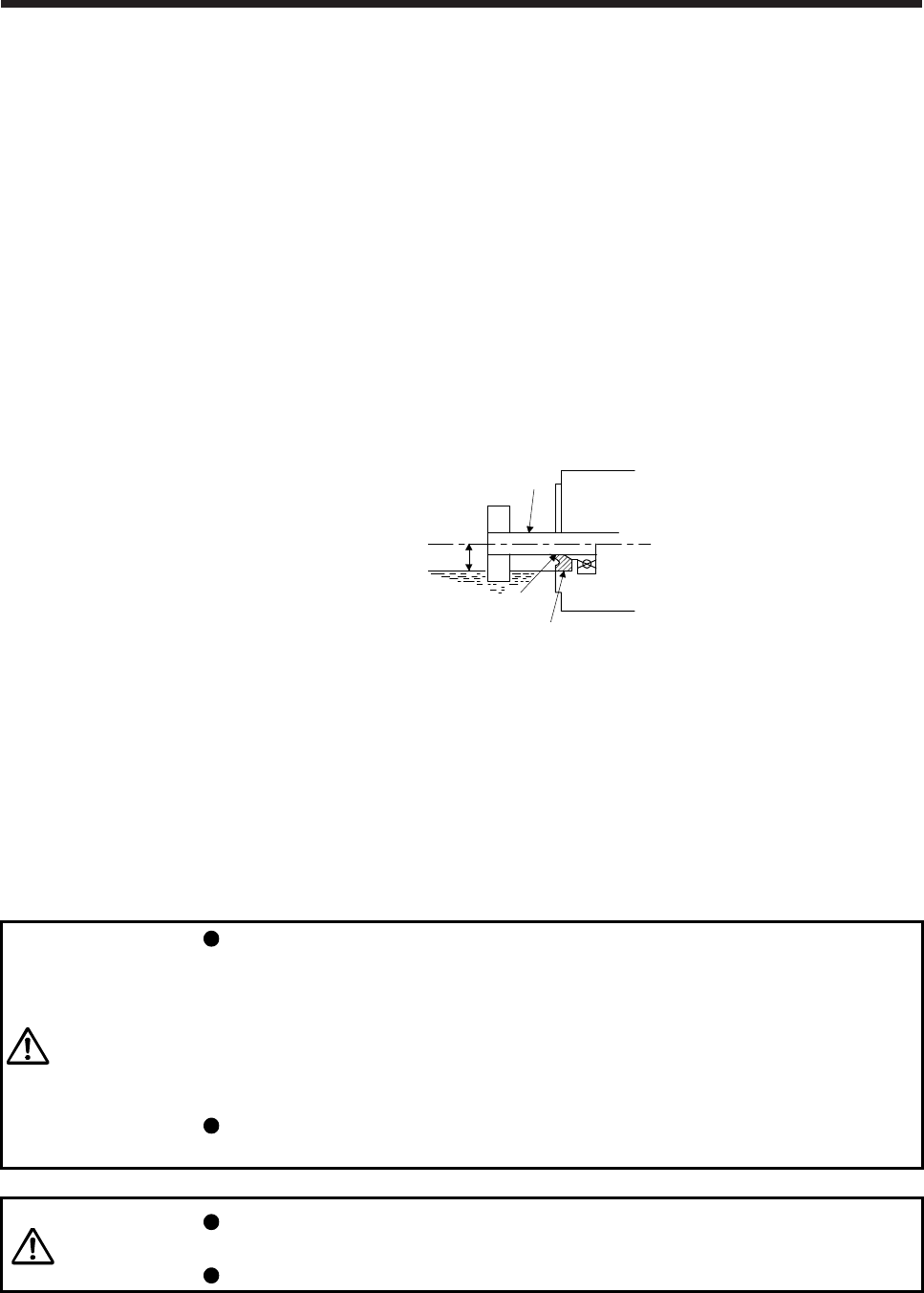

(1) Pressure and oil level

Install the servo motor horizontally, and set the oil level in the gear box to be lower than the oil seal lip

always. If the oil level is higher than the oil seal lip, the oil enter the servo motor and may cause a

malfunction. Refer to the chapter of the servo motor series for the oil level.

Gear

Shaft

Servo motor

Oil seal

Height above oil level h

Lip

High pressure against the oil seal causes the abrasion and makes the life be short. Keep constant

internal pressure by equipping a ventilator to the gear box.

(2) Temperature

High temperature against the oil seal lip makes the life be short. Avoid exposing the oil seal lip to high

temperature oil since applicable temperature of the material is up to 100 °C and temperature of the oil

seal lip rises within 10 °C to 15 °C at maximum rotation.

2.8 Inspection items

WARNING

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more (20 minutes or more for converter unit and drive unit) until the

charge lamp turns off. Then, confirm that the voltage between P+ and N- (L+ and

L- for converter unit and drive unit) is safe with a voltage tester and others.

Otherwise, an electric shock may occur. In addition, when confirming whether the

charge lamp is off or not, always confirm it from the front of the servo amplifier

(converter unit).

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair and parts replacement, contact your local sales office.

CAUTION

Do not perform insulation resistance test on the servo motor. Otherwise, it may

cause a malfunction.

Do not disassemble and/or repair the equipment on customer side.

It is recommended that the following points periodically be checked.

(1) Check the bearings, brake section, etc. for unusual noise.