A - 3

CAUTION

Stacking in excess of the specified number of product packages is not allowed.

Do not carry the servo motor by holding the cables, shaft, encoder, or connector.

Install the servo motor in a load-bearing place in accordance with the Instruction Manual.

Do not get on or put heavy load on the equipment.

The equipment must be installed in the specified direction.

Do not install or operate the servo motor which have been damaged or have any parts missing.

Do not block intake and exhaust areas of the servo motor with a cooling fan. Otherwise, it may cause a

malfunction.

Do not drop or strike the servo motor. Isolate it from all impact loads.

Securely fix the servo motor to the machine. If being attached insecurely, the servo motor may come off

during operation.

The geared servo motor must be installed in the specified direction to prevent oil leakage.

When handling the servo motor, be careful about the edged parts such as the corners of the servo motor.

Be sure to measure the motor vibration level with the servo motor mounted to the machine when

checking the vibration level. A great vibration may cause the early damage of a bearing, encoder, brake,

and reducer. The great vibration may also cause the poor connector connection or bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and the speed waveform

with a measurement device, and then check that no vibration occurs. If the vibration occurs due to high

gain, the vibration may cause the early damage of the servo motor.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotor of the servo motor

during operation.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. Otherwise,

the encoder may malfunction.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

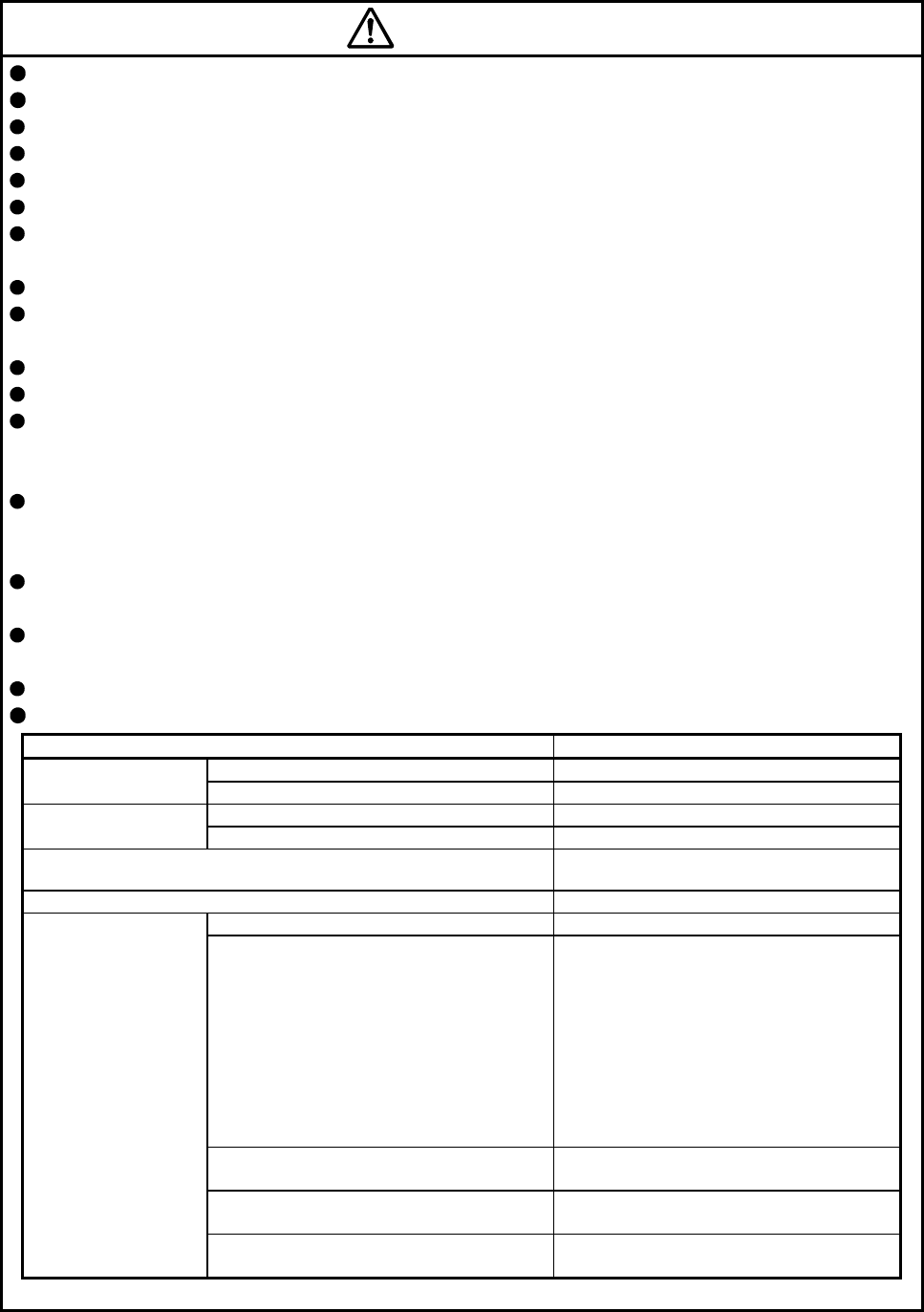

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient temperature

Operation 0 °C to 40 °C (non-freezing)

Storage -15 °C to 70 °C (non-freezing)

Ambient humidity

Operation 80 %RH or less (non-condensing)

Storage 90 %RH or less (non-condensing)

Ambience

Indoors (no direct sunlight), free from corrosive

gas, flammable gas, oil mist, dust, and dirt

Altitude Max. 1000 m above sea level

Vibration resistance

(Note)

HG-MR Series/HG-KR Series/HG-AK Series X, Y: 49 m/s

2

HG-SR51/HG-SR81/HG-SR52(4)/

HG-SR102(4)/HG-SR152(4)/HG-JR53(4)/

HG-JR73(4)/HG-JR103(4)/HG-JR153(4)/

HG-JR203(4)/HG-JR353(4)/HG-JR503(4)/

HG-JR701M(4)/HG-JR11K1M(4)/

HG-JR15K1M(4)/HG-JR22K1M(4)/

HG-JR30K1M(4)/HG-JR37K1M(4)/

HG-JR601(4)/HG-JR801(4)/HG-JR12K1(4)/

HG-JR15K1(4)/HG-JR20K1(4)/HG-JR25K1(4)/

HG-RR Series/HG-UR72/HG-UR152

X, Y: 24.5 m/s

2

HG-SR121/HG-SR201/HG-SR202(4)/

HG-SR352(4)/HG-UR202/HG-UR352/HG-UR502

X: 24.5 m/s

2

Y: 49 m/s

2

HG-SR301/HG-SR421/HG-SR502(4)/

HG-SR702(4)/HG-JR703(4)/HG-JR903(4)

X: 24.5 m/s

2

Y: 29.4 m/s

2

HG-JR45K1M4/HG-JR55K1M4/

HG-JR30K1(4)/HG-JR37K1(4)

X: 9.8 m/s

2

Y: 9.8 m/s

2

Note. Except the geared servo motor.