WARNING

Before removing the sensor, be absolutely certain

that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

Model 404

ENDURANCE

™

Conductivity Sensor

Instruction Sheet

PN 51A-404/rev.M

December 2010

If the sensor is installed in a sidestream

with the sample draining to open atmos-

phere, bubbles may accumulate on the

electrodes. Trapped bubbles will cause

errors. Normally, as bubbles accumu-

late the conductivity reading drifts down.

To control bubble formation, apply a small

amount of back pressure to the sensor.

SENSOR SPECIFICATIONS

SPECIFICATIONS

MODEL 404-16 (PVC body) MODEL 404-17 (stainless steel body)

Wetted Materials Titanium, PEEK (glass filled), PVC, Titanium, PEEK (glass filled),

EPDM, polyethylene 303 SST, EPDM

Temperature Range 32-140°F (0-60°C) 32-212°F (0-100°C)

Maximum Pressure 20 psig (239 kPa abs) at 60°C (140°F) 100 psig (791 kPa abs)

100 psig (791 kPa abs) at 25°C (77°F)

(use FNPT fittings only)

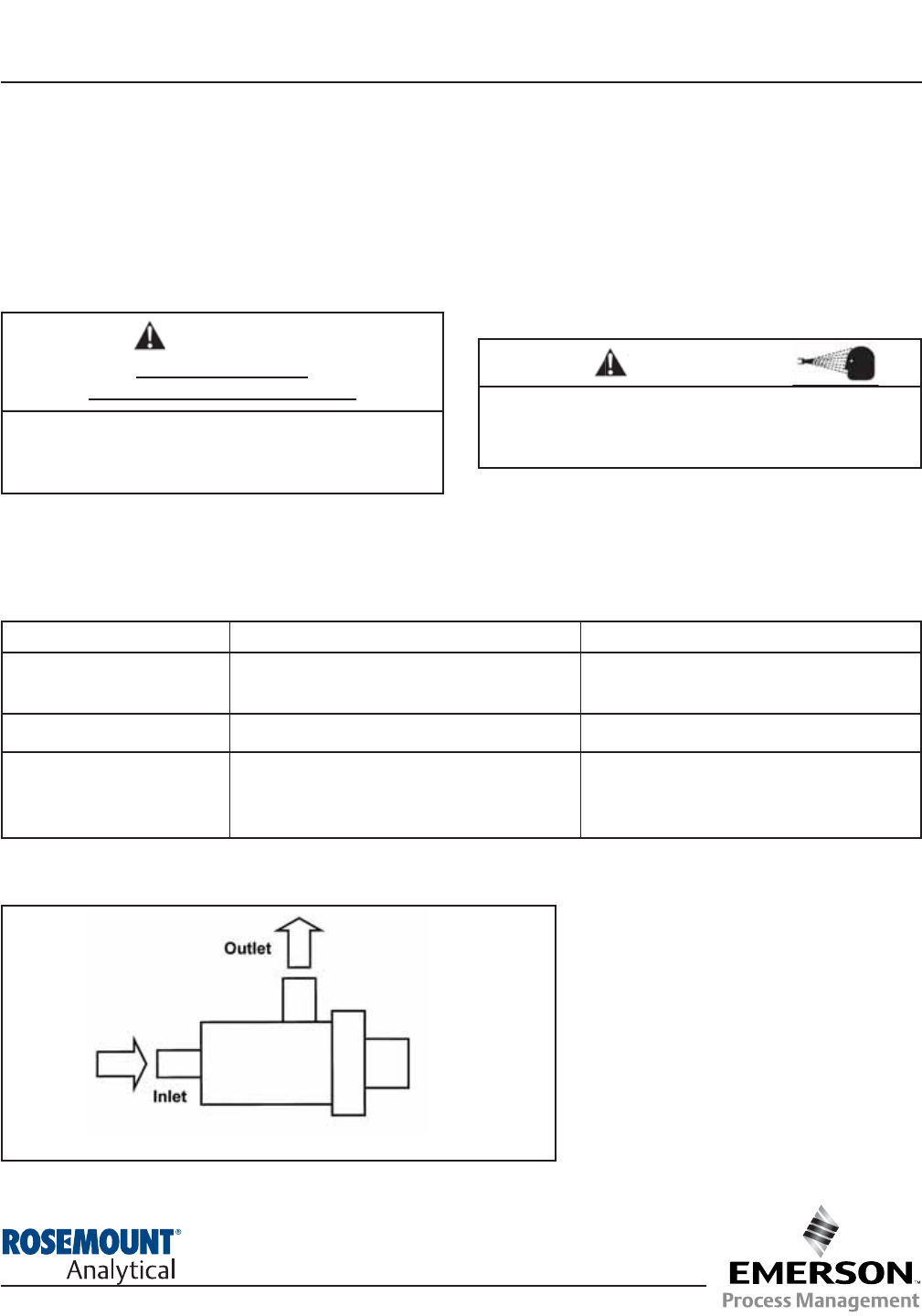

FIGURE 1. Installation of Model 404 Sensor

For additional information, please visit our website

at www.emersonprocess.com/raihome/liquid/.

INSTALLATION

The wetted sensor materials may not be compatible

with process com position and operating conditions.

Application compat ibility is entirely the

responsi-

bility of the user.

CAUTION

SENSOR/PROCESS

APPLICATION COMPATIBILITY

WARNING