Pre-Installation

1. Visually inspect the CWBT for any damage. If damage exists

return product for replacement.

Installation

This product must be installed by a

qualified professional.

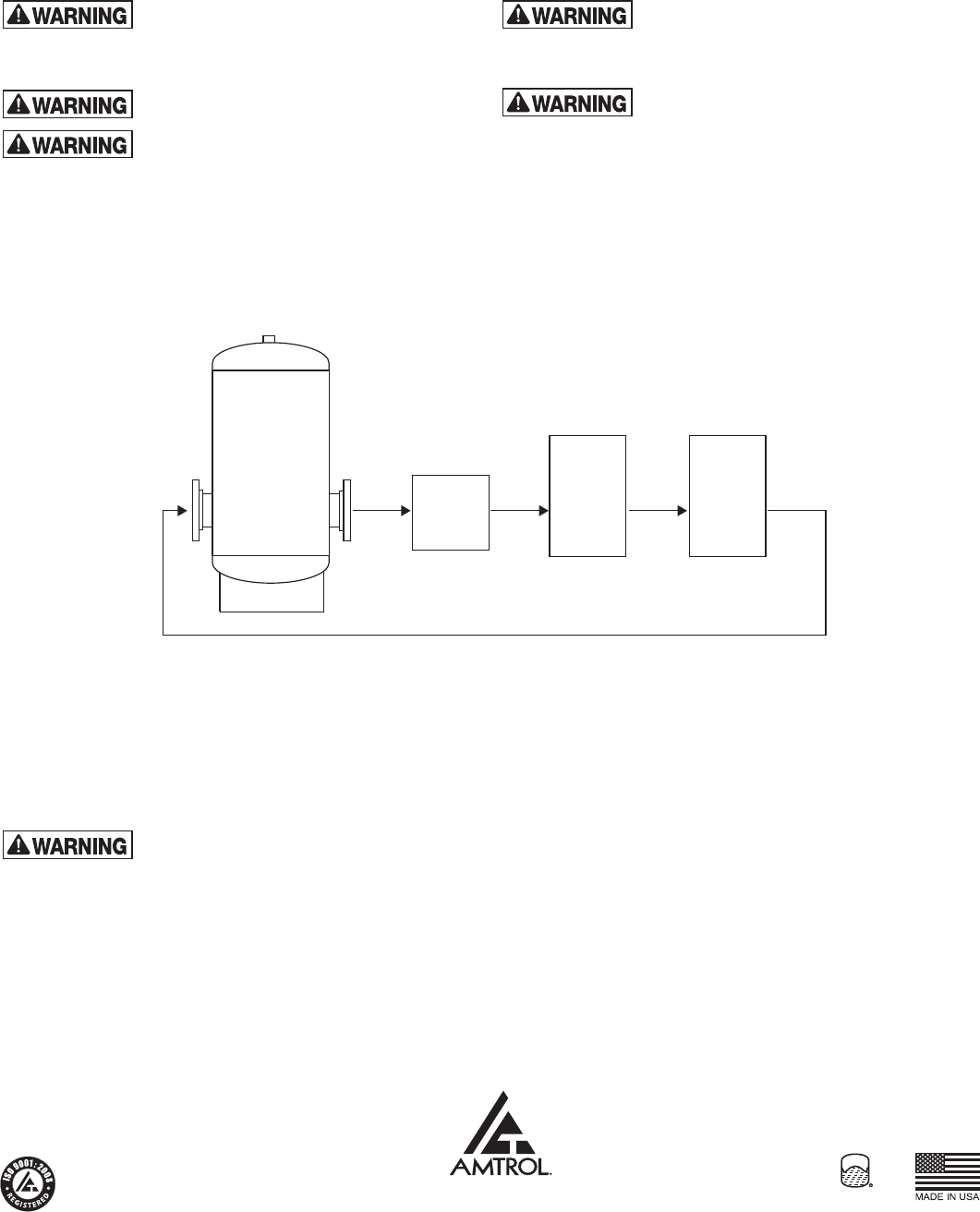

1. Refer to Figure 1 for typical installation of the AMTROL

CWBT Series.

Maintenance

1. Aqualiedprofessionalshouldcheckthecompletesystem,

including the CWBT, yearly and more frequently as the

system ages.

Operation

1. The CWBT models are designed to add capacity to non-

potable, closed, chilled water systems to help reduce

compressor unit cycling, improve temperature control and

provide more consistent system operation.

2. Water temperature is not to exceed 450°F.

3. System pressure is not to exceed the maximum working

pressure of the tank.

Warranty

CWBT120-3 through CWBT1040-12 Models:

One (1) Year Limited Warranty

Visit www.amtrol.com for complete warranty details.

Chlorine & Aggressive Water. The water quality

can significantly influence the life of this product.

You should test for corrosive elements, acidity, total solids and other

relevant contaminants, including chlorine and treat your water appropriately

to insure satisfactory performance and prevent premature failure.

Welding to the pressure vessel boundary will

void the ASME rating.

Leaking, corrosion or indications of damage are

signs of an impending serious failure of the

buffer tank. Periodically inspect for damage and if noted the product

must be serviced or replaced. Failure to follow these instructions

could result in serious personal injury or death and

property damage.

Water temperature above 100°F can be very

hazardous. Allow system water temperature to

cool down below 100°F before blowing down this product. Failure to

follow these instructions could result in serious personal injury or

death and property damage.

EXPLOSION OR RUPTURE HAZARD. A relief

valve must be installed to prevent pressure in

excess of local code requirement or maximum working pressure

designated in the Product Manual, whichever is less. At least once every

3 years or if discharge is present, a licensed contractor should inspect the

temperature and pressure relief valve and replace if corrosion is evident

or the valve does not function. FAILURE TO INSPECT THIS VALVE AS

DIRECTED COULD RESULT IN UNSAFE TEMPERATURE OR

PRESSURE BUILD-UP WHICH CAN RESULT IN PRODUCT FAILURE,

SERIOUS INJURY OR DEATH AND/OR SEVERE PROPERTY

DAMAGE AND VOID THE PRODUCT WARRANTY.

PUMP

BUFFER

TANK

OTHER VALVES AND ACCESSORIES REQUIRED FOR SYSTEM INSTALLATION ARE NOT SHOWN.

CHILLER

AIR

HANDLER

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY

IMPORTANT GENERAL SAFETY INFORMATION -

ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING INSTRUCTIONS.

© 2015 AMTROL Inc. Part #: 9017-156 (01/15)

Mark of the

Originator

1400 Division Road, West Warwick, RI USA 02893

T: 800.426.8765 F: 800.293.1519

www.amtrol.com

Figure 1