PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY

IMPORTANT GENERAL SAFETY INFORMATION -

ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING INSTRUCTIONS.

FILL-TROL

®

is a combination of an EXTROL

®

expansion tank and

a specially designed automatic pressure reducing valve. Together,

they manage water expansion to provide satisfactory heating system

performance.

The EXTROL is pre-charged at the factory to 12 PSIG and is ready

to install in most residential and light commercial systems without

adjustment. The valve is designed to fill the system with water and

automatically shut off the flow when it reaches the precharge pressure

in the tank. It will also restore the system to 12 PSIG if the pressure

drops below that point. The precharge may be changed to set the

desired fill pressure.

Pre-Installation

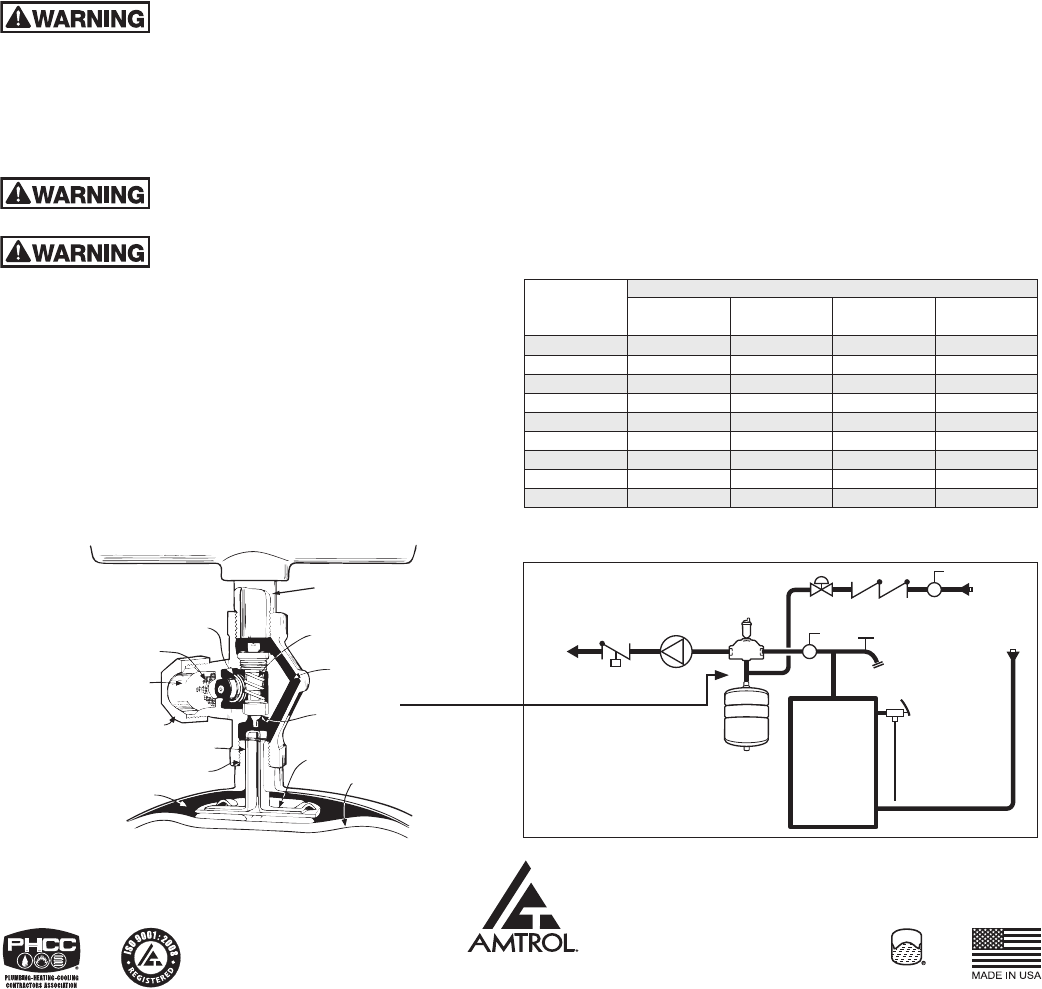

1 Visually inspect for any damage. Ensure expansion tank is sized

properly for application (Figure 1).

2. Remove plastic cap from air valve.

3. With tank empty of water, adjust air precharge to desired system fill

pressure. Unit is shipped at 12 PSIG.

4. Replace and tighten plastic cap on air valve.

FAILURE TO PROPERLY SEAL VALVE CAP

WILL RESULT IN LOSS OF PRECHARGE

CAUSING PRODUCT TO FAIL.

Installation

1. Drain the boiler system or isolate the area where the unit will

be installed.

2. Install the unit on the supply side of the boiler, on the suction-side of

the heating circulator(s) (Figure 2).

Mount tank vertically only. Ensure the piping

can support the entire weight of the tank when

full of water.

Do not install on a dead-end pipe or wherever

air can collect; causing internal corrosion and

possible leakage.

3. Make connection to system with 1/2" pipe nipple from tapping marked

SYSTEM.

4. Connect cold water supply to 1/2" compression fitting connection at

SUPPLY.

5. Pressurize the system and check for leaks. Repair as necessary.

6. Restart the boiler system and check for relief valve discharge. If the

relief valve drips, the tank may be improperly charged or undersized.

7. The unit is now operational and will absorb expanded water during

boiler operation.

Maintenance

To remove screen in Fill-Trol valve for cleaning, shut off main water

supply to heating system and remove compression nut.

A professional plumber should check the complete system,

including the expansion tank, yearly and more frequently as the

system ages. Checking the precharge allows a small amount of

air to escape and can result in an insufficient air charge. Always

check the precharge while the tank is isolated and empty of water.

Be sure to maintain the proper precharge whenever the tank

is inspected.

Operation

Water enters the Fill-Trol valve through the 1/2" compression fitting

connection, passes through the removable strainer and pushes open

the spring-loaded check valve. It then flows through the automatic shut-

off valve which is held in the open position by the diaphragm pushing

against the pressure plate. This raises the fill-gate stem and compresses

the automatic shut-off valve spring allowing water to flow into the heating

system. It is the charge pressure in the tank that forces the diaphragm

into position.

As the system reaches the fill pressure, the diaphragm moves, allowing

the automatic shut-off valve to close.

When the system falls below the fill pressure, the diaphragm again

pushes open the automatic shut-off valve, allowing water to flow into the

system and restore system pressure.

The Fill-Trol is shipped with a factory precharge of 12 PSIG which

automatically sets the minimum fill pressure to 12 PSIG. Other minimum

fill pressures my be used by increasing or decreasing the air charge in the

tank. Carefully follow the instructions for changing the air charge.

Warranty

FT Models: Five (5) Year Limited Warranty

Visit www.amtrol.com for complete warranty details.

Figure 1.

Figure 2.

System

Supply

Flow-Check

Valve

Circulator

Air

Purger

Air Vent

Fill-Trol

Expansion

Tank

Fill-Trol Valve

Relief

Valve

Boiler

System

Return

Shut-Off

Valve

Water

Supply

Pressure-

Reducing

Valve

Shut-Off

Valve

System

Purge

Backflow

Preventer

Boiler

Net Output

in 1000’S

of BTU/Hr.

Type of Radiation

Finned Tube

Baseboard or

Radiant Panel

Convectors

or Unit

Heaters

Radiators

Cast Iron

Baseboard

Cast Iron

25 FT-109 FT-109 FT-109 FT-109

50 FT-109 FT-109 FT-110 FT-110

75 FT-110 FT-110 FT-110 FT-111

100 FT-110 FT-110 FT-111 FT-111

125 FT-110 FT-111 FT-111 NA

150 FT-110 FT-111 NA NA

175 FT-111 FT-111 NA NA

200 FT-111 FT-111 NA NA

250 FT-111 NA NA NA

Sizing based on: 12 psig Fill; 30 psig Relief Valve; 200°F Average Temperature.

© 2014 AMTROL Inc. Part #: 9015-026 (06/14)

Mark of the

Originator

1400 Division Road, West Warwick, RI USA 02893

T: 800.426.8765 F: 800.293.1519

www.amtrol.com

Spring-Loaded

Check Valve

Automatic Shut-Off

Valve Spring

Pipe Nipple

Expansion

Bypass

Automatic

Shut-Off Valve

Pressure Plate

Removable

Strainer

Cold Water

Supply

Fill Gate

Stem

O-Ring Seal

1/2˝ Compression

Fitting Connection

System Pressure

Above Diaphragm

Diaphragm