Sizing Chart

Amtrol

Pressuriser

®

Minimum

Flow Rate

From City

Supply

Minimum

Flow Pressure

From City

Supply

Minimum

Incoming

Pipe Size

Water

Meter

RP-10HP 10 gpm 10 psig

3

/4"

3

/4"

RP-15HP 15 gpm 10 psig 1" 1"

RP-25HP 25 gpm 10 psig 1

1

/4" 1

1

/4"

Metal piping must be used for all inlet and outlet lines to the unit.

Do not oversize pump. Inadequate water supply will result in

poor performance and pump damages.

Pre-Installation

• DONOTUSEFORPRE-HEATEDWATERSUPPLIES;

• DO NOT USE FOR ANYTHING EXCEPT COLD WATER

(AMBIENTTEMPERATURENOTTOEXCEED100°F);

• DO NOTUSE INSYSTEMS WHERELOW PRESSUREIS

DUE TO LEAKS OR WHERE LEAKS IN THE PLUMBING

SYSTEMMAYEXIST;

• DONOTUSEINSYSTEMSWHERETHEWATERSUPPLY

CANDROPBELOW10PSIG;

• DO NOTUSE IN SERIESWITH ANOTHERPUMP (SUCH

ASINPRIVATEWELLWATERSYSTEMS);

• DO NOT RE-PRESSURIZED TANK AFTER INITIAL

INSTALLATION;

• DO NOT PIPE EXCEPT WITH METAL PIPING AT INLET

AND OUTLETS.

The system must be placed indoors only on a solid level

surface with a drip pan piped to a drain with adequate capacity

for large volumes of water in the event the system ruptures or

fails. Consider the risks posed by tanks under pressure and the

potential for leaking and/or flooding damage in selecting the

location. The unit must not be placed in an environment that would

expose the water in the tank to temperatures below freezing or in

excess of 100° F.

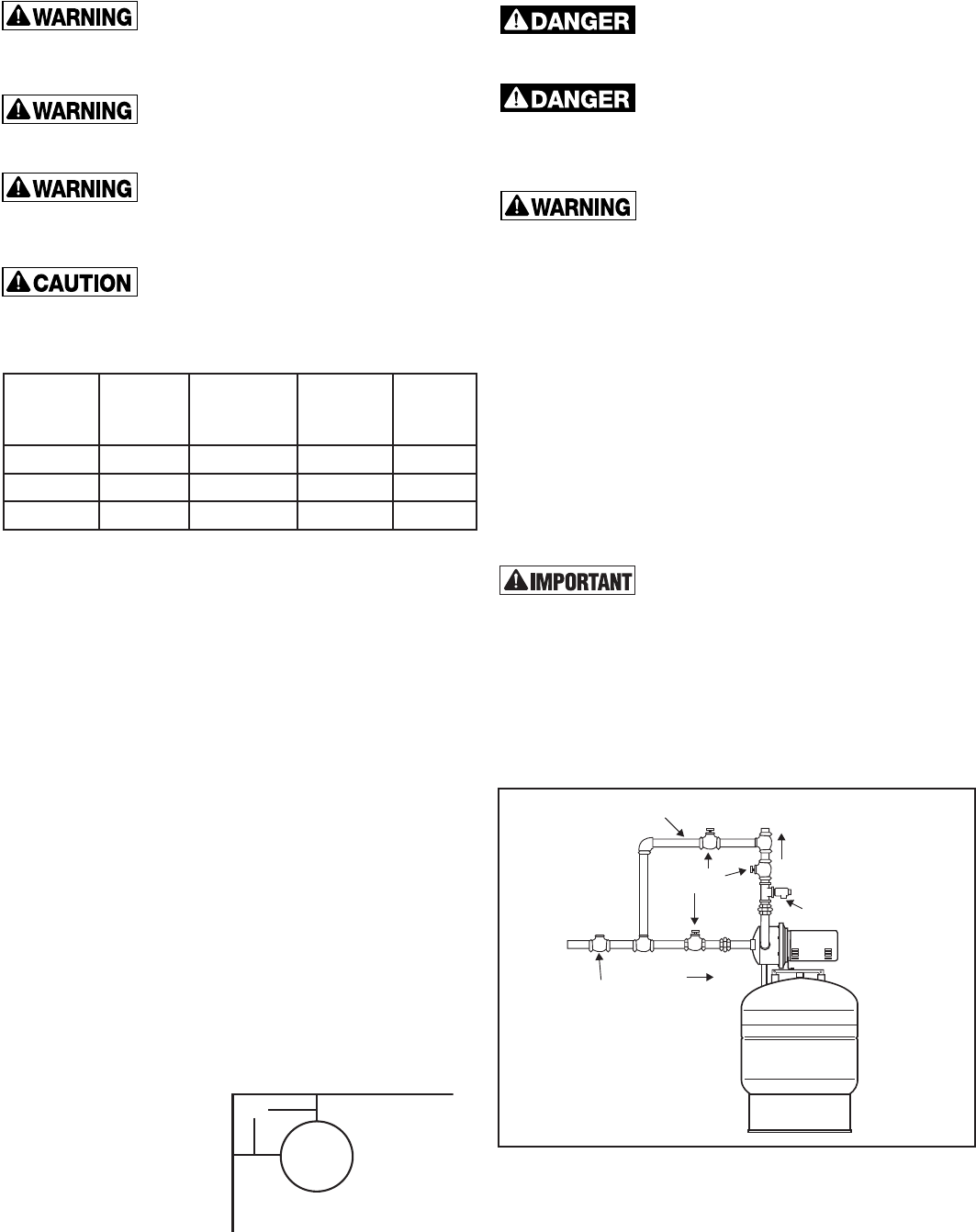

Be sure to leave a minimal

clearance of 12” around

the unit for access should

field adjustments be

necessary in the future

and to permit maintenance

and inspection (Figure 1).

Installation

1. Remove protective air valve cap.

2. Check pre-charge pressure (pressure should be + or – 10% of

the factory setting). Factory pre-charge is 38 psig.

3. Release or add air as necessary to make the pre-charge

pressure 2 psig below the pressure switch pump cut-in setting.

4. Replace protective air valve cap. (Remove air valve label,

replace protective air valve cap, peel off backing of label and

apply on air valve cap.)

MINIMUM SUPPLY LINE AND METER SIZE FOR

THE RP-10HP IS

3

/4", THE RP-15HP IS 1" AND

THE RP-25HP IS 1

1

/4". THIS APPLIES TO ALL LINES INCLUDING

THOSE USED WITH THE WATER METER OR FITTINGS BEFORE THE

PUMP. CONTACT FACTORY IF MINIMUM FITTING/LINE SIZE IS

BELOW THE ABOVE NUMBERS.

5. Install a SPRING LOADED CHECK VALVE in the city supply

line on the suction side of the pump along with a shut-off valve.

Failure to do so will result in premature failure of the AMTROL

Pressuriser due to excessive pump cycling.

6. Install a by-pass loop (Figure 2).

7. Pipe the city supply after the shut-off valve to the suction side

of the pump, as shown.

8. Connect the house supply line using a 100 psig maximum relief

valve as shown (Figure 2). It is important that the pressure

relief valve be installed on the pump discharge prior to any

shut off valves.

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY

IMPORTANT GENERAL SAFETY INFORMATION -

ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING INSTRUCTIONS.

If the control is set too high or the pump is running

when the water supply is shut off and there is no

demand on the system, the pump will run continuously, can overheat

and become damaged, potentially resulting in product failure, leaking

and/or rupture.

All wire and fuse sizings are preliminary

recommendations only. For your safety, local

codes, and in their absence, national codes must be followed to minimize

the risk of electric shock, property damage or personal injury.

The pump motor is designed for use with single

phase, 60Hz ac. Use with any other type of power

will cause damage to the motor. The pump models RP-10HP, RP-15HP

and RP25-HP are pre-wired for 115 vac; however, they can be rewired to

be used with 230 vac. Consult motor nameplate for the wiring diagram.

The power for your pump must be on a dedicated

circuit. In addition, a shut off switch should be

visible and near the pump. Use a 20 amp circuit.

Before attempting any service and disassembly,

shut off power to the pump. Ensure power is

disconnected prior to removing motor. Ensure power is disconnected

before cleaning is attempted.

Grounding of the pump is essential for your

protection and the protection of the motor. All wiring

should be completed by a licensed electrician, and in accordance with

local codes or in their absence, the National Electrical Code. Before

starting the wiring installation, disconnect all power to the circuit to be

used for the AMTROL Pressuriser

®

.

The AMTROL Pressuriser

®

should only be

connected to a municipal, cold water supply, and in

systems with a minimum pressure of 10 psig at all times, measured under

flow at the tap closest to the location of the AMTROL Pressuriser

®

installation.

12"

Amtrol Pressuriser

®

Figure 1

SPRING

CHECK VALVE

FLOW

FLOW

BYPASS

LOOP

PRESSURE

RELIEF

VALVE

CITY

WATER

SUPPLY

TO SYSTEM

SHUT-OFF

VALVES

RP-10HP

RP-15HP

RP-25HP

Figure 2