© 2015 AMTROL Inc. Part #: 9015-183 (06/15)

Mark of the

Originator

1400 Division Road, West Warwick, RI USA 02893

T: 800.426.8765 F: 800.293.1519

www.amtrol.com

Pre-Installation

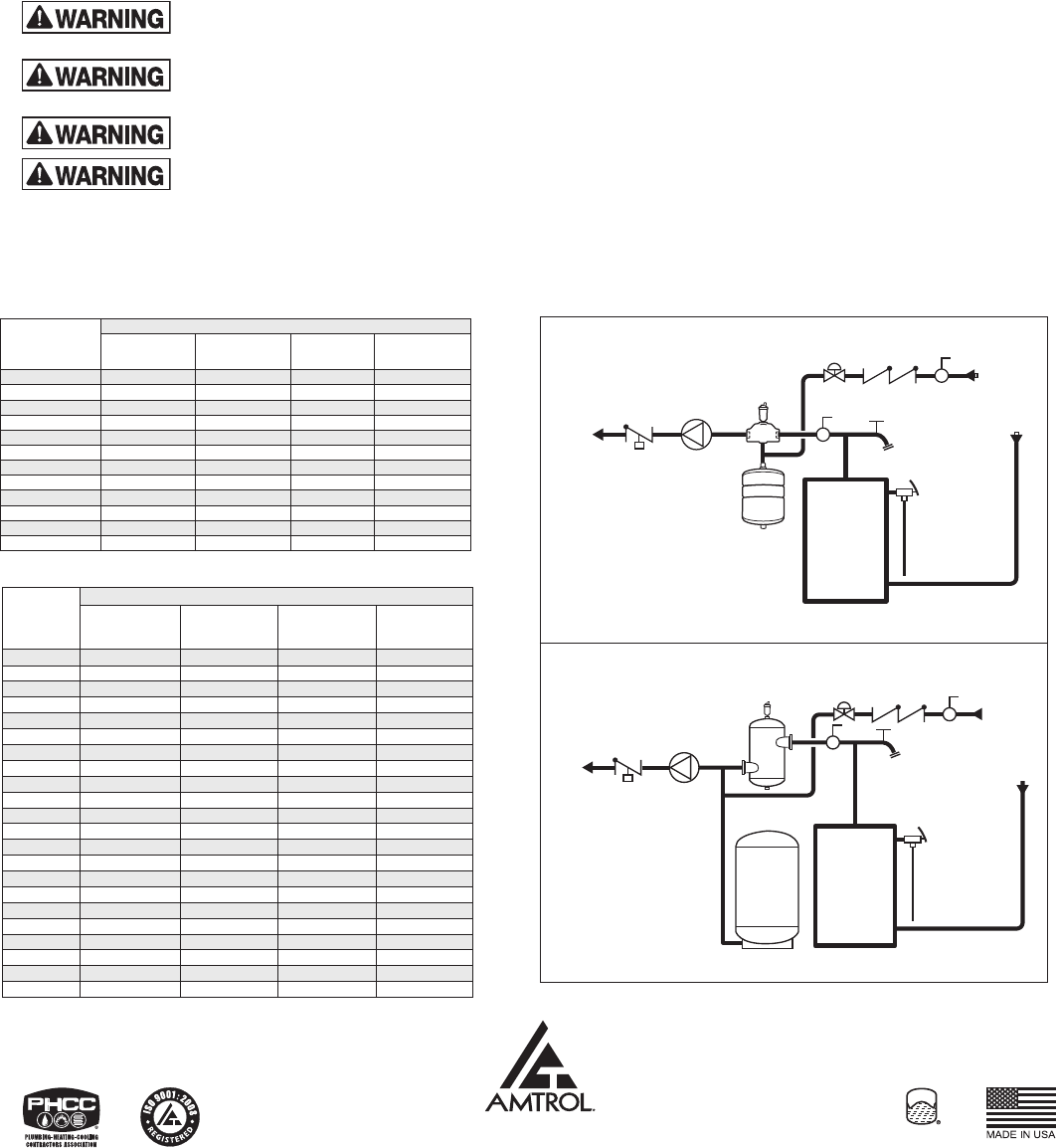

1 Visually inspect for any damage. Ensure expansion tank is sized

properly for application (Figure 1).

2. Remove plastic cap from air valve.

3. With tank empty of water, adjust air precharge to match system fill

pressure.

4. Replace and tighten plastic cap on air valve.

FAILURE TO PROPERLY SEAL VALVE CAP

WILL RESULT IN LOSS OF PRECHARGE

CAUSING PRODUCT TO FAIL.

Mount tank vertically in downward position only.

Ensure the piping can support the entire weight

of the tank when full of water.

Models SX-30V through SX-160V are floor

standing and may not be hung from the piping.

Do not install the EXTROL on a dead-end pipe

or wherever air can collect. This can cause

corrosion and possible leakage.

Installation

1. Drain the boiler system or isolate the area where the EXTROL will

be installed.

2. Install the EXTROL on the supply side of the boiler, on the suction-side

of the heating circulator(s) (Figure 2).

3. Pressurize the system and check for leaks. Repair as necessary.

4. Restart the boiler system and check for relief valve discharge. If the

relief valve drips, the tank may be improperly charged or undersized.

5. The EXTROL is now operational and will absorb expanded water

during boiler operation.

Maintenance

A professional plumber should check the complete system,

including the expansion tank, yearly and more frequently as the

system ages. Checking the precharge allows a small quantity of

air to escape and can result in an insufficient air charge. Always

check the precharge while the tank is isolated and empty of water,

and be sure to maintain the proper precharge whenever the tank

is inspected.

Warranty

EX Models: Five (5) Year Limited Warranty

SX Models: One (1) Year Limited Warranty

Visit www.amtrol.com for complete warranty details.

Figure 1.

Figure 2.

Boiler

Net Output in

1000’s of BTU

Type of Radiation and Piping System

Finned Tube

Baseboard or Radiant

Panels with Series

Loop System

Convectors or

Unit Heaters

with One Pipe

System

Radiators

or

One Pipe

System

Cast Iron

Radiators

with Series

Loop System

200 SX- 30V SX-30V SX-30V SX-30V

250 SX- 30V SX-30V SX-30V SX-40V

300 SX- 30V SX-30V SX-40V SX-40V

350 SX-30V SX-30V SX-40V SX-60V

400 SX-30V SX-40V SX-60V SX-60V

450 SX-40V SX-40V SX-90V SX-90V

500 SX-40V SX-40V SX-60V SX-90V

550 SX-40V SX-60V SX-60V SX-90V

600 SX-40V SX-60V SX-90V SX-90V

650 SX-60V SX-60V SX-90V SX-90V

700 SX-60V SX-60V SX-90V SX-90V

750 SX-60V SX-60V SX-90V SX-110V

800 SX-60V SX-90V SX-90V SX-110V

850 SX-60V SX-90V SX-90V SX-110V

900 SX-60V SX-90V SX-110V SX-110V

950 SX-90V SX-90V SX-110V SX-110V

1,000 SX-90V SX-90V SX-110V SX-110V

1,100 SX-90V SX-90V SX-110V SX-130V

1,200 SX-90V SX-90V SX-110V SX-130V

1,300 SX-90V SX-110V SX-130V SX-160V

1,400 SX-110V SX-130V SX-160V SX-160V

1,500 SX-110V SX-130V SX-160V (2)SX-110V

Sizing based on: Average Boiler Water Volume; Average Water Volume;

Fill Pressure 12 psig; Relief Pressure 30 psig

Air

Separator

System

Supply

Flow-Check

Valve

Circulator

Air Vent

Extrol

Expansion

Tank

Relief

Valve

System

Return

Shut-Off

Valve

Water

Supply

Pressure-

Reducing

Valve

Shut-Off

Valve

System

Purge

Backflow

Preventer

Boiler

System

Supply

Flow-Check

Valve

Circulator

Air

Purger

Air Vent

Extrol

Expansion

Tank

Relief

Valve

Boiler

System

Return

Shut-Off

Valve

Water

Supply

Pressure-

Reducing

Valve

Shut-Off

Valve

System

Purge

Backflow

Preventer

Boiler

Net Output

in 1000’S

of BTU/Hr.

Type of Radiation

Finned Tube

Baseboard or

Radiant Panel

Convectors

or Unit

Heaters

Radiators

Cast Iron

Baseboard

Cast Iron

25 EX-15 EX-15 EX-15 EX-15

50 EX-15 EX-15 EX-30 EX-30

75 EX-30 EX-30 EX-30 EX-60

100 EX-30 EX-30 EX-60 EX-60

125 EX-30 EX-60 EX-60 EX-90

150 EX-30 EX-60 EX-90 EX-90

175 EX-60 EX-60 SX-30V SX-30V

200 EX-60 EX-60 SX-30V SX-30V

250 EX-60 EX-90 SX-30V SX-40V

300 EX-90 SX-30V SX-30V SX-40V

350 SX-30V SX-30V SX-40V SX-60V

400 SX-30V SX-40V SX-40V SX-60V

Sizing based on: 12 psig Fill; 30 psig Relief Valve; 200°F Average Temperature.

In-Line Models:

EX-15 through EX-90

Stand Models:

SX-30V through SX-160V

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY

IMPORTANT GENERAL SAFETY INFORMATION -

ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING INSTRUCTIONS.