22

Shoot-Thru-Hull Preparation

Hulls With Flotation Materials

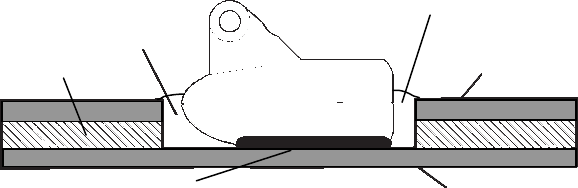

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass lay-

ers. The sonar signal must pass through solid fiberglass. A successful

transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood or foam) between layers of fiberglass if

the material is removed from the chosen area. See the figure below.

WARNING:

Do not remove any material from your inner hull unless

you know the hull's composition. Careless grinding or

cutting on your hull can result in damage that could

sink your boat. Contact your boat dealer or manufac-

turer to confirm your hull specifications.

Epoxy the transducer to a solid portion of the hull.

For example, some (but not all) manufacturers use a layer of fiberglass,

then a core of balsa wood, finishing with an outer layer of fiberglass. Re-

moving the inner layer of fiberglass and the balsa wood core exposes the

outer layer of fiberglass. The transducer can then be epoxied directly to

the outer layer of fiberglass. After the epoxy cures for 24 hours, fill the

remaining space with polyester resin. When the job is finished, the hull

is watertight and structurally sound. Remember, the sonar signal must

Fill with resin

Inner hull

Epoxy to hull first

Outer hull

Flotation material

Fill with resin