OPERATING PRECAUTIONS

This is a kerosene, direct-fired, forced air heater. It's intended use

is primarily temporary heating of buildings under construction,

alteration or repair.

Direct-Fired means that all of the combustion products enter the

heated space. Even though this heater operates very close to 100

percent combustion efficiency, it still produces small amounts of

carbon monoxide. Carbon monoxide (called CO) is toxic. We can

tolerate small amounts but not a lot. CO can build up in a heated

space and failure to provide adequate ventilation could result in

death. The symptoms of inadequate ventilation are:

• headache

• dizziness

• burning eyes and nose

• nausea

• dry mouth or sore throat

So, be sure to follow advice about ventilation in these operating

instructions.

Forced Air means that a blower or fan pushes the air through

the heater. Proper combustion depends upon this air flow;

therefore, the heater must not be revised, modified or operated

with parts removed or missing. Likewise, safety systems must not

be circumvented or modified in order to operate the heater.

When the heater is to be operated in the presence of other

people the user is responsible for properly acquainting those

present with the safety precautions and instructions, and of the

hazards involved.

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT operate

a damaged heater.

2. DO NOT modify the heater or operate a heater which has

been modified from its original condition.

3. Use only Kerosene. Never use gasoline, naphtha, paint

thinner, alcohol or other fuels of any kind.

4. For indoor use only. Not for use where exposed to weather.

5. Use in well ventilated areas, provide at least 2 sq. ft. (0.19

sq. m.) of opening near the floor and 2 sq. ft. (0.19 sq. m.)

SPECIFICATIONS

Type of Fuel: For use with Kerosene or #1 Fuel Oil ONLY on ALL models.

Model ...................................... 50K .............................................75KT ....................................... 125KT ....................................... 175KT

Burn Rate: ................................ 50,000 Btu/hr (15 kW) ...............75,000 Btu/hr (22 kW) ......... 125,000 Btu/hr (37 kW) ........... 175,000 Btu/hr (51 kW)

Fuel Rate: ................................. 0.37 gal/hr (1.4 L/hr) ................. 0.55 gal/hr (2.1 L/hr) ............. 0.96 gal./hr (3.5 L/hr) ............. 1.3 gal/hr (5.0 L/hr)

Electrical Input: ........................ 115V, 60Hz, 3.5a .........................115V, 60Hz, 4a ....................... 115V, 60Hz, 5.5a ...................... 115V, 60Hz, 5.5a

Line Protection:........................ 10 amps...................................... 10 amps ................................. 20 amps ................................... 20 amps

Min. Operating Voltage: .......... 110V ............................................110V ....................................... 110V ......................................... 110V

Pressure Setting: ...................... 3.5 psig (24 kPa) ........................ 4.2 psig (29 kPa) .................... 5.0 psig (34 kPa) ...................... 5.8 psig (40 kPa)

Max. Outlet Temperature:........ 1300

o

F (704

o

C) ............................1300

o

F (704

o

C) ....................... 1300

o

F (704

o

C) ......................... 1300

o

F (704

o

C)

Fuel Tank Capacity: .................. 4 gallons (15.1 L) ........................6 gallons (22.7 L) ................... 14 gallons (53 L) ...................... 14 gallons (53 L)

Ignition: ................................... Direct Spark, Continuous............ Direct Spark, Continuous ....... Direct Spark, Continuous ......... Direct Spark, Continuous

Spark Generator: ..................... Igniter 13 kV, 10ma ....................Igniter 13 kV, 10ma ................ Igniter 13 kV, 10ma .................. Igniter 13 kV, 10ma

Primary Safety Control: ............ Solid State Control...................... Solid State Control ................. Solid State Control ................... Solid State Control

Certification:

near the ceiling directly to outdoors. Increase air openings as

marked for each additional heater.

6. Always keep combustibles, like paper and wood at least 8

ft. (2.4 m) from the heater outlet and 3 ft. (1.0 m) from the

top, sides and inlet. Locate 10 ft. (3.0 m) from canvas or

plastic coverings and secure them to prevent flapping

movement.

7. Caution: Due to the high surface and exhaust temperatures,

adults and children must observe clearances to avoid burns

or clothing ignition. Do Not Touch. Keep Children, Clothing,

and Combustibles away.

8. Install the heater such that it is not directly exposed to

water spray, rain and / or water.

9. Never use in areas normally for habitation and /or where

children may be present.

10. Operate only on a stable, level surface. (MH50K & MH75KT

– See wood floor warning).

11. Do not use with duct work. Do not restrict inlet or exit.

12. Use only with electrical power specified. The electrical

connection and grounding must comply with National

Electrical Code – ANSI/NFPA 70 (USA) and CSA C22.1

Canadian Electrical Code, Part 1 (Canada).

13. Use only a properly grounded 3-prong receptacle or

extension cord.

14. Do not move, handle, or service while hot or burning.

15. Use only in accordance with local, state (provincial) or

National requirements, ordinances and codes.

OPERATING INSTRUCTIONS

UNPACKING

1. Remove all protective material which may have been applied

to the heater for shipment.

2. Remove heater from carton.

3. Check the heater for possible shipping damage. If any

damage is found immediately notify the dealer from whom

you purchased the heater.

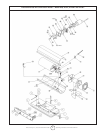

ASSEMBLY (For 125,000 and 175,000 BTU/hr models only)

Wheel and handles are found in the shipping carton along with

mounting hardware. The wheels, axle and mounting hardware

are in a package. Tools required are a 5/16" nutdriver, 3/8"

open or adjustable wrench and standard pliers.

3

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’s Manual