6 Thru-Hull Intelliducer Installation Instructions

Drilling and Preparing a Cored Fiberglass Hull

When installing the Intelliducer in a cored berglass hull, you must take precautions to

carefully seal and reinforce the core. Seal and reinforce the core with either berglass or with

casting epoxy.

CAUTION: If the core of a cored berglass hull is not sealed and reinforced properly, water may

seep into the core and severely damage the boat. In addition, the boat may sink.

WARNING: Always wear a dust mask and safety goggles when drilling, cutting, ling, and

sanding.

1. Drill a

1

/

8

in. (3 mm) pilot hole from the inside of the boat.

2. On the outside of the boat, ensure the pilot hole is in the correct location; if not, seal the

incorrect pilot hole with epoxy and re-drill the pilot hole in a better location.

3. Use a hole saw to cut a 2 in. (51 mm) hole from the outside of the boat through the outer

skin only. Do not cut completely through the hull.

4. On the inside of the boat, at the pilot hole location, use a hole saw to cut a hole

3

/

8

–

1

/

2

in.

(9–12 mm) larger than the hole through the outer skin. Cut through the inner skin and most

of the core.

CAUTION: When cutting the inner skin and core, be extremely careful to not cut the outer skin, or

you will not be able to correctly seal the hull.

5. Remove the plug containing the inner skin and core material on the inside of the boat. You

should be able to see the inside of the outer skin.

6. Sand the inside of the outer skin around the hole, the core, and the area around the hole

in the inner skin. Clean the area using a mild detergent or weak solvent (such as isopropyl

alcohol), to remove any dust and dirt.

1. Frominsidetheboat,coatalayerofberglassclothwithberglassresinandplaceitinthe

hole to seal the core.

2. Add layers until the hole is the correct diameter of 2 in. (51 mm).

3. After the material has hardened, sand and clean the hole and areas around the inside and

outside of the hole.

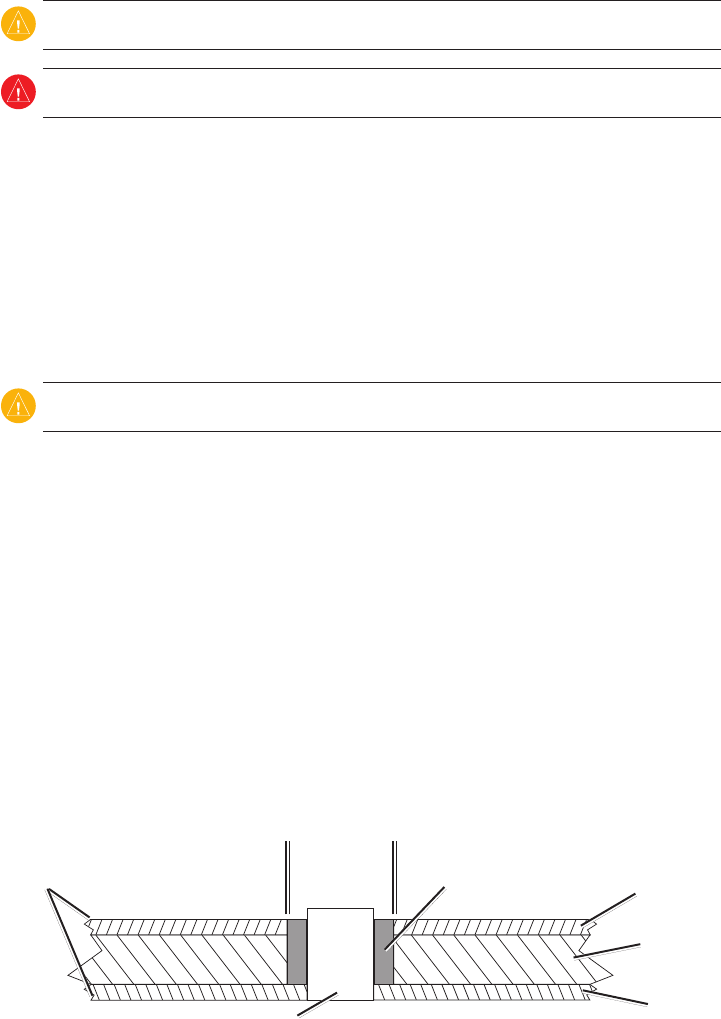

To seal the core with casting epoxy:

1. Coat a 2 in. (51 mm) cylinder with wax.

2. Insert the cylinder in the hole through the outer skin and tape it in place.

Cylinder

Hull

Inner skin

Outer skin

Core

Casting epoxy

2

3

/

8

–2

1

/

2

in.

(60–63 mm)

hole

3. Fill the gap between the cylinder and the core with casting epoxy.

4. After the epoxy has hardened, remove the cylinder.

5. Sand and clean the hole and areas around the inside and outside of the hole.