6 308647

Installation

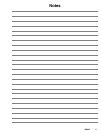

H

Multiple Circulating Spray Station

Key

A Air regulator

B Bleed-type master air valve

C Pump

D Fluid filter and drain valve

E Main fluid supply line

F Gun fluid supply line

G Fluid regulator

with fluid pressure gauge (H)

H Fluid pressure gauge

J Air-assisted airless spray gun

K Back pressure valve

L Fluid return line

M Main circulating line

N Fluid supply container

P Drain valve

A

B

C

D

E

F

J

K

M

K

L

A

B

C

G

D

J

Single Direct Spray Station

G

N

F

Fig. 1

06461

J

P

G

P

06462

P

H

H

WARNING

Do not use PTFE tape on pipe threads. Such use

could cause a hazardous condition due to loss of

grounding continuity. Also, if pieces of the tape break

off, the function of the regulator could be affected.

The installations shown in Fig. 1 are only a guide for

selecting and installing a circulating or direct system;

they are not actual system designs. Contact your

Graco distributor for assistance in designing a system

to suit your needs.

NOTE: Before you install the regulator, thoroughly

flush the system to remove metal chips and other

contaminants. A fluid filter (D) of 60-mesh or finer

should always be installed upstream of the regulator.

Connections

Install the fluid regulator (G) in the spray gun fluid

supply line (F), as shown in the typical installation

drawings on this page. Connect only one spray gun

or dispensing valve to each fluid regulator.

Apply pipe sealant to the male pipe threads, and

connect the fluid supply line (F) to the fluid regulator’s

3/8 npt(f) inlet. Connect the line from the gun (J) to the

fluid regulator’s 3/8 npt(f) outlet. Install the gauge or

plug into the 1/4 npt(f) gauge port.

Make sure the direction of fluid flow agrees with the IN

and OUT markings on the regulator body.

Flush the System

The regulator was tested in lightweight oil. Flush the

entire system with a solvent compatible with the fluid

being dispensed. Then test the system.

Mounting Bracket

A Mounting Bracket is available for mounting the

regulator. Order Part 222515 for the bracket and

mounting hardware.