Repair

8 3A1211M

Repair

Preventive Maintenance

Schedule

The operating conditions of your system determine how

often maintenance is required. Establish a preventive

maintenance schedule by recording when and what kind

of maintenance is needed, and then determine a regular

schedule for checking your system.

Pressure Relief Procedure

1. Shut off the air supply to the pump.

2. Close the bleed-type master valve (required in sys-

tem).

3. Open the fluid ball valve and/or dispensing valve to

relieve fluid pressure.

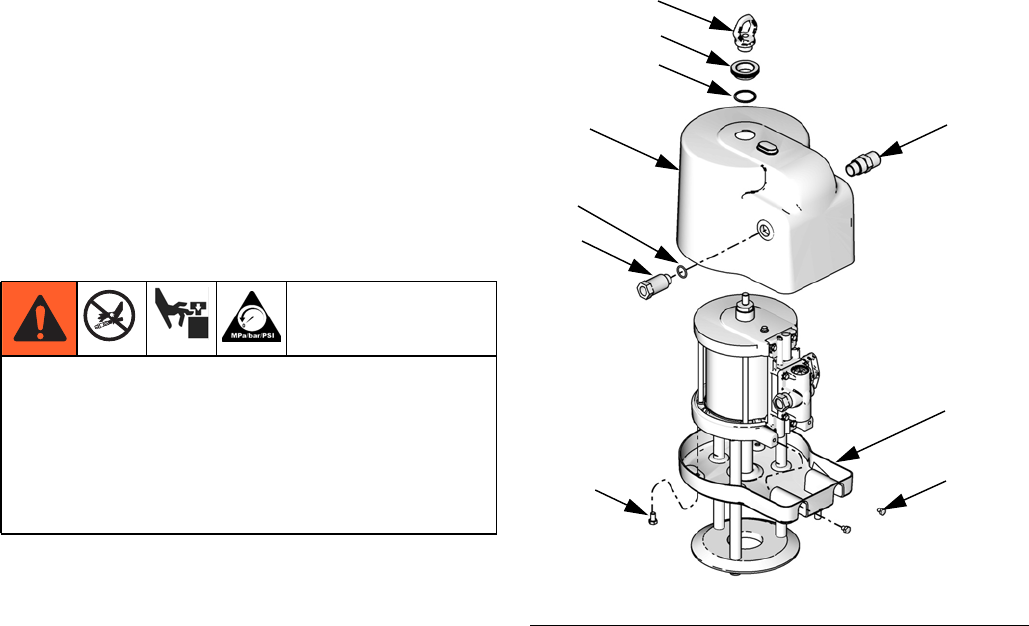

Remove the Shroud

1. Stop the pump at the middle of its stroke. Follow

Pressure Relief Procedure, page 8.

2. Disconnect air lines.

3. Remove exhaust fitting (42) and air inlet fitting (43)

with o-ring (44).

4. Remove the lift ring (41), hand screw (40), and

o-ring (39).

5. Lift the top shroud (46) straight up off the motor.

6. Remove four screws (48). Slide the bottom shroud

(47) down.

• Trapped air can cause the pump to cycle unexpect-

edly, which could result in serious injury from skin

injection or moving parts.

• Relieve pressure when you stop pumping and

before cleaning, checking, or servicing equipment.

• Do not lift or move motor while pressurized.

FIG. 2. Shroud removal

ti16226a

43

42

41

40

39

46

47

48

48

44