6 307886

Maintenance

Flushing

D Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

D Flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary.

D Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

1. Record the pressure adjustment setting of the

regulator before flushing.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

2. Shut off the pump and relieve fluid pressure in the

system by triggering the gun and opening the back

pressure valve or other bypass valve.

3. Never exceed the maximum working pressure of

the lowest rated system component.

4. Open the fluid regulator by turning the adjusting

screw (18) fully clockwise.

5. Supply solvent to the system. Set pump to the

lowest possible pressure, and start pump.

6. Flush until thoroughly clean.

7. Adjust the fluid regulator to return to the desired

fluid pressure setting.

Cleaning

NOTE: Do not allow fluid to settle in the system.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

1. Relieve the pressure.

2. Remove the regulator. Clean and inspect all parts.

CAUTION

Handle the hard carbide parts, ball (5), valve actuator

(9), and seat (6) carefully to avoid damaging them.

Damage will cause poor operation and leakage.

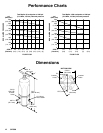

Cartridge Replacement

NOTE: Kit 222140 replaces the fluid regulator valve

cartridge. See page 10 for the parts included.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

1. Relieve the pressure.

2. Remove the cartridge by loosening the valve

housing (1) and pulling the cartridge assembly out

of the regulator housing (24). See Fig. 1.

3. Install the new cartridge assembly into the

regulator housing (24). Torque the valve housing

(1) to 30 to 35 ft-lbs (41 to 47 NSm).

Fig. 1

1*

Torque to

30 to 35 ft-lb

(41 to 47 N-m)

24