MT692C

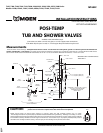

WITHOUT STOPS

WITH STOPS

7"

7"

SHOWER

SHOWER

SUPPLY

TUB

TUB

SUPPLY

SUPPLY

2-3/4" C.C.

& I.P.S.

2-5/16" C.C.

& I.P.S.

4-13/16" C.C.

4-5/16"

NOMINAL

4-1/2"

PLASTER

GROUND

SIZE AND

WALL

OPENING

C.C. I.P.S.

CLAMP

SCREW

CAUTION

This valve is equipped with the Moen

long-life POSI-TEMP cartridge,

designed for smooth, trouble-free

operation. When soldering do not heat

valve any higher than necessary to flow

the solder. Overheating may damage

the cartridge or rubber stop valves.

Following this direction will allow you

to solder without removing the car-

tridge or rubber stop valves.

WARNING: The cartridge and rubber

stop valves MUST be removed before

either brazing or resistance (electric)

soldering.

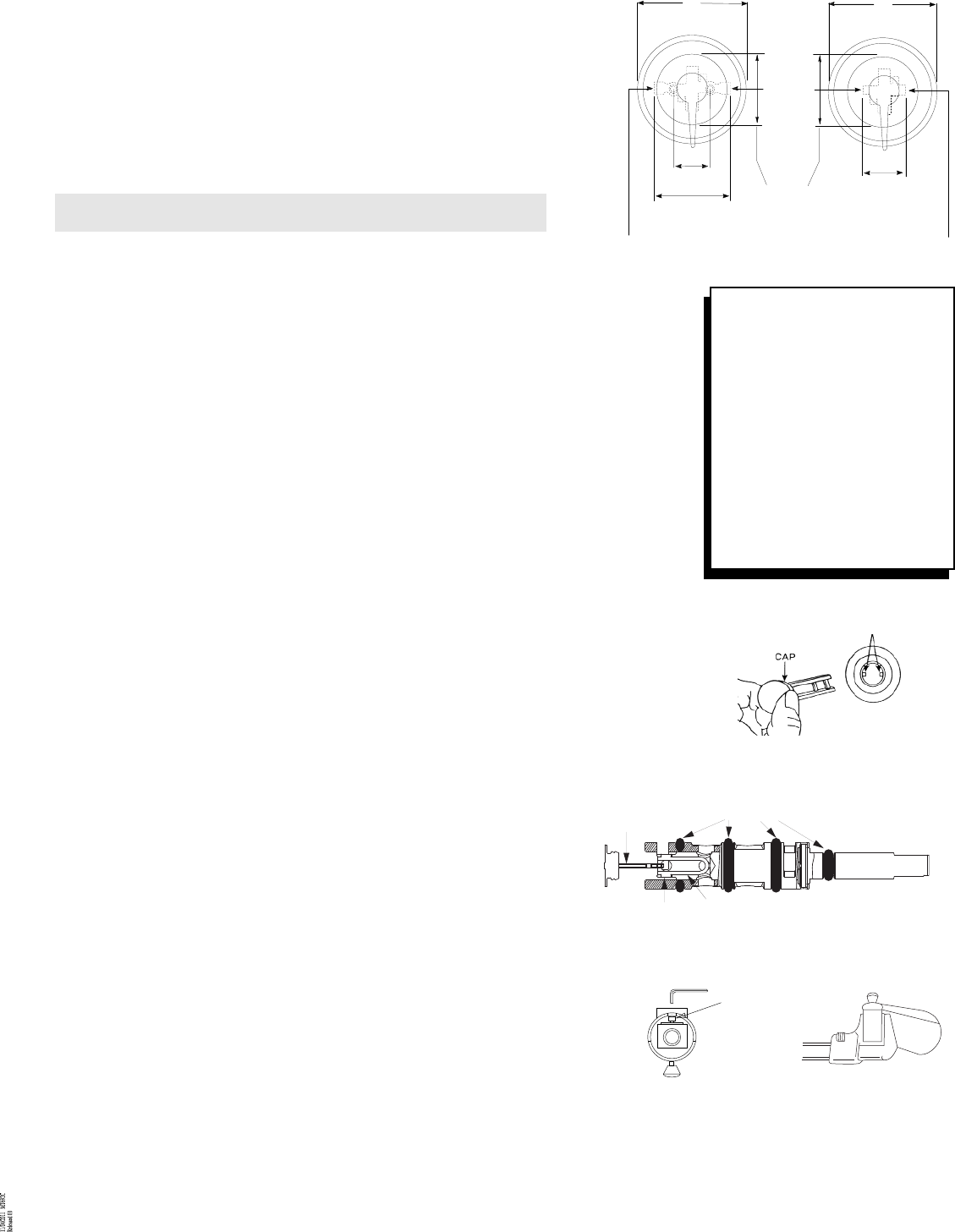

CLIP/BARS

ORIENT THE CLIP IN THE SPOOL AND THE

CAP FINGERS AS SHOWN ABOVE.

CAP

O-RINGS

CLIP/BARS

STEM ASSEMBLY

BALANCE

SPOOL

Stop Operation

CC - This type is integral with casting, actuated by screwdriver, and require a 90° turn to

open or close. When the screwdriver slot is vertical, the rubber stop is closed, and when

the slot is horizontal, the rubber stop is open.

IPS - This type has been added to the basic shower casting and is actuated by a screwdriv-

er. The stop is opened by rotating in a counterclockwise direction until it stops and closed

by rotating in a clockwise direction until it bottoms.

MAKE SURE ALL WATER SUPPLIES ARE OFF.

Note the word "TOP" on the casting. Install casting with the TOP facing UP. If the valve is to be

used for a shower only, plug the bottom outlet. If the valve is to be used for both a shower and

a tub, connect the top outlet to the shower and the bottom outlet to the tub. Secure all pipes

and the shower and tub drop ells. Use thread seal tape on all threads.

Rough-In

Flushing

IMPORTANT: Before closing all wall openings, pressure test valve and complete sys-

tem using flushing instructions

Pipe chips, sand and other solids found in new and renovated plumbing can damage the sealing surfaces

of the cartridge causing a leak or cause the spool to become blocked. To avoid damage, DO NOT

TURN ON SUPPLY VALVES until instructed below.

Make sure both hot and cold supplies are off. Rotate the cartridge stem until the notched flat points up to

relieve pressure and insure complete shut-off. Remove the cartridge assembly (see "Disassembly").

Slowly turn on both hot and cold supplies and thoroughly flush out the body and lines. Close the hot and

cold supplies and replace the cartridge assembly (see "Reassembly"), turn on both supplies and check the system

for leaks.

If the balancing spool becomes stuck, it will be apparent at the trim-out test in that the valve will deliver only a

small trickle of water, or it will deliver only hot or cold water. If this occurs, proceed as follows:

Make sure that both the hot and cold water service lines are "ON". Also make sure that both rubber stop valves

are open (stop models). The valve WILL NOT OPERATE unless both supplies are "ON".

If the valve still does not function properly, turn off BOTH the hot and cold supplies and remove the cartridge

assembly. A cartridge twisting tool is required for this. The inner spool in the cartridge assembly should shake

back and forth freely. If this does not happen, remove the stem assembly from the cartridge sleeve, remove the

cap from the stem assembly and remove the balance spool. Sometimes the stem assembly may have to be jarred

to free the spool. Carefully clean any foreign material from the balance spool and stem assembly and reassemble

(see illustration). CAUTION: DO NOT DAMAGE O-RINGS. The spool should move back and forth after the stem

assembly is cleaned. If spool still does not free up, replace the entire cartridge assembly.

Make sure O-rings are free of foreign material and are lubricated. Re-assemble stem

assembly into cartridge sleeve. Re-assemble cartridge into valve. (See "Reassembly").

Turn both water supplies on. The valve should function properly.

Slip-Fit spouts

C.C. SPOUT: The Moen Slip Fit spout is designed with an O-ring seal. It is specifically

designed for installation with copper water tube. Lookout must be free from burrs

inside and out. The edge must not be rolled inward from a dull tubing cutter. The

outside surface must be free from nicks and scratches.

Press and twist the spout onto the lookout upside down. Tighten the clamp screw

with a 5/32" hex wrench until it just starts to bind. Turn spout upright into position

against the wall and finish tightening the clamp screw by hand. The use of pliers or

another wrench on the hex wrench is not necessary. Do not overtighten.

IPS SPOUT:

CAUTION: This spout is A.B.S. plastic and will crack when in contact with some pipe thread compounds.

Please read the pipe compound label to be certain. We recommend using thread seal tape thread sealant.

Screw tub spout onto pipe and tighten by hand. If final turn by wrench is needed, use small wrench with smooth jaws;otherwise, pad wrench teeth with rag.

Pull outward on spout while tightening to avoid scratching wall. DO NOT INSERT TOOL INTO SPOUT END TO TURN SPOUT.