©2012 The Toro Company

Micro-Irrigation Business

1588 N. Marshall Avenue, El Cajon, CA 92020-1523, USA

Tel: +1(800) 333-8125 or +1(619) 562-2950

Fax: +1(800) 892-1822 or +1(619) 258-9973

toro.com

ALT057 1/04

600 Series Valves

Additional Features:

• Self-cleaning In-line filter for filtration

of the command system water

• Non-continuous metering system –

since only a small exchange of

control water is used to operate the

main valve, the system is less

susceptible to failure due to plugging

• Available in 2" and 3" (51 and 76mm)

• Working pressure is 10 to 150 psi

(.7 to 10.3 bar)

• Flow range from 80 gpm to 300 gpm

(5.0 to 18.9 l/s)

• Manual external bleed

• Glass reinforced nylon body and

bonnet give superior high

temperature strength

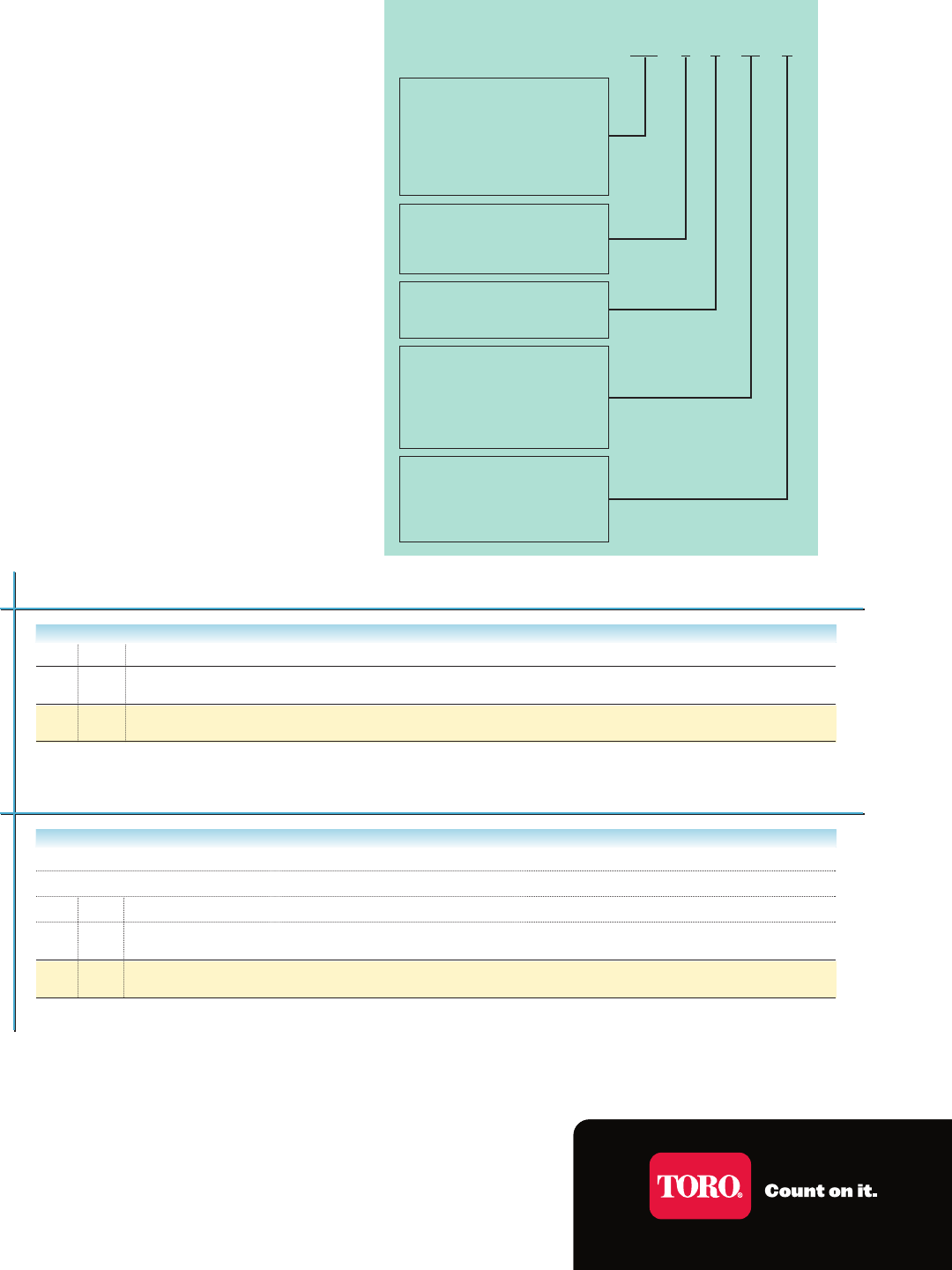

Understanding 600 Series Valves Part Numbers

Example: 601 –3–T– 01 –B

Valve Category

B

asic Hydraulic –600

P

ressure Reducing –601

P

ressure Sustaining/Relief –602

P

ressure Reducing and –603

S

ustaining/Relief Valve

Valve Size

T

wo-inch Valve –2

Three-inch Valve –3

Options

Three Position Selector Valve –T

Electric Control

N

o Solenoid –00

Solenoid 24VAC –01

24 VDC Latching –02

9 – 12 VDC Latching –03

Pilot Springs

5–20psi Blue –B

9–35psi Green –G

21–113psi Silver –S

Pressure Loss in PSI

Flow Rate (GPM)

Style Size 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 175 200 225 250 275 300

Globe

2"

2.1 2.7 3.3 4.0 4.8 5.6 6.5 7.5

Angle 1.2 1.6 2.0 2.4 2.8 3.3 3.9 4.4

Globe

3"

2.5 3.0 4.1 5.3 6.7 8.3 10.1

Angle 1.9 2.4 3.3 4.3 5.5 6.9 8.5

Pressure Loss in Bar

Flow Rate

Liters/second 0,5 1,0 1,5 2,0 3,0 4,0 5,0 6,0 7,0 8,0 9,0 10,0 11,0 12,0 13,0 14,0 15,0 16,0 17,0 18,0 19,0

M

3

/Hour 1,8 3,6 5,4 7,2 10,8 14,4 18,0 21,6 25,2 28,8 32,4 36,0 39,6 43,2 46,8 50,4 54,0 57,6 61,2 64,8 68,4

Style Size

Globe

50mm

0,14 0,21 0,28 0,37 0,47

Angle 0,08 0,12 0,17 0,22 0,28

Globe

75mm

0,18 0,21 0,25 0,30 0,35 0,41 0,48 0,54 0,62 0,70

Angle 0,14 0,16 0,20 0,24 0,29 0,34 0,39 0,45 0,52 0,59

NOTES: (1) When designing a system, the industry standard for flow rate velocity through pipes and fittings is 5 Fps (2m/s).

(2) Pressure loss data is derived from valves independently tested by C.I.T., Fresno, CA.

(3) Hydraulic actuated valves vented to atmosphere will show lower pressure loss figures at low flows.

(4) Pressure regulating valves must operate in the recommended flow ranges – For the best pressure regulation the

valves should be sized at the upper end of the flow range.