168106-PUM-A-1205

Unitary Products Group 5

Motor Lubrication

The motors in these furnaces are permanently lubricated, and do not

require periodic oiling.

SECTION II: SERVICE AND MAINTENANCE

MANUAL

SAFETY SECTION

The following safety rules must be followed when servicing the

furnace.

FURNACE MAINTENANCE SECTION

The furnace should be cleaned and adjusted by a certified dealer or

qualified service contractor once a year or before the start of every

heating season. The following items must be cleaned and serviced or

replaced if there are signs of deterioration.

1. The vent terminal screen (if applicable).

2. The furnace vent and combustion air intake passageways. Should

it be necessary to service the vent/air intake system, the manufac-

turer recommends this service be conducted by a qualified service

agency. The operation of this appliance requires the reassembly

and resealing of the vent/air intake system.

3. The furnace burners, ignitor and flame sensor.

4. The condensate collection and disposal system. If any disassem-

bly of components containing flue or vent gases is required, a

qualified service agency must perform the service.

SEQUENCE OF OPERATION

The following describes the sequence of operation of the furnace. Refer

to Figure 1 for component location.

Continuous Blower

Cooling/heating thermostats have a fan switch that has an ON and

AUTO position. In the ON position the thermostat circuit is completed

between terminals R and G.

Intermittent Blower - Cooling

Cooling/heating thermostats have a fan switch that has an ON and

AUTO position. In the AUTO position the thermostat circuit is completed

between terminals R and G when there is a call for cooling. The motor

will operate on the speed tap wire that is connected to the HI COOL ter-

minal on the control board. The fan off setting is fixed at 60 seconds for

SEER enhancement.

Heating Cycle

When the thermostat switch is set on HEAT and the fan is set on AUTO,

and there is a call for heat, a circuit is completed between terminals R

and W of the thermostat. When the proper amount of combustion air is

being provided, the pressure switch will close, the ignition control pro-

vides a 17-second warm-up period, the gas valve then opens, the gas

starts to flow, ignition occurs and the flame sensor begins its sensing

function. The blower motor will energize 30 seconds after the gas valve

opens, if a flame is detected. Normal furnace operation will continue

until the thermostat circuit between R and W is opened, which causes

the ignition system and gas valve to de-energize and the burner flames

to be extinguished. The vent motor will operate for 15 seconds and the

blower motor will operate for the amount of time set by the fan-off delay

jumper located on the control board. See Figure 7. The heating cycle is

complete, and ready for the start of the next heating cycle.

If the flame is not detected within 7 seconds of the gas valve opening,

the gas valve is shut off and a retry operation begins. If the flame is lost

for 2 seconds during the 10-second stabilization period, the gas valve is

shut off and a retry operation begins. During a retry operation, the vent

motor starts a 15 second inter-purge and the ignitor warm-up time is

extended to 27 seconds. If the flame is established for more than 10

seconds after ignition during a retry, the control will clear the ignition

attempt (retry) counter. If three retries occur during a call for heat, the

furnace will shut down for one hour. If at the end of the one hour shut

down there is a call for heat, the furnace will initiate a normal start cycle.

If the problem has not been corrected the furnace will again lockout

after three retries.

A momentary loss of gas supply, flame blowout, or a faulty flame probe

circuit will result in a disruption in the flame and be sensed within 1 sec-

ond. The gas valve will de-energize and the control will begin a recycle

operation. A normal ignition sequence will begin after a 15 second inter-

purge. If during the five recycles the gas supply does not return, or the

fault condition is not corrected the ignition control will lockout for 60 min-

tues.

During burner operation, a momentary loss of power for 50 milliseconds

or longer will de-energize the gas valve. When the power is restored,

the gas valve will remain de-energized and the ignition sequence will

immediately restart.

TABLE 1:

Filter Sizes

Input/Output

BTU/H (kW)

CFM

(m

3

/min)

Cabinet

Size

Top Return Filter

in (cm)

40/37(11.72/10.84) 1200(34) A (2) 14 x 20 (36 x 51)

60/55(17.57/16.10) 1200 (34) B (2) 14 x 20 (36 x 51)

80/75(23.42/21.96) 1200 (34) B (2) 14 x 20 (36 x 51)

80/75(23.42/21.96) 1600 (45) C (2) 14 x 20 (36 x 51)

100/95(29.28/27.82) 1600 (45) C (2) 14 x 20 (36 x 51)

100/95(29.28/27.82) 2000 (57) C (2) 14 x 20 (36 x 51)

120/112(35.14/32.80) 2000 (57) D (2) 14 x 20 (36 x 51)

ELECTRIC SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in

dangerous operation, serious injury, death or property

damage.

Improper servicing could result in dangerous operation,

serious injury, and death or property damage.

• Before servicing, disconnect all electrical power to the fur-

nace.

• When servicing controls, label all wires prior to discon-

necting. Reconnect wires correctly.

• Verify proper operation after servicing.

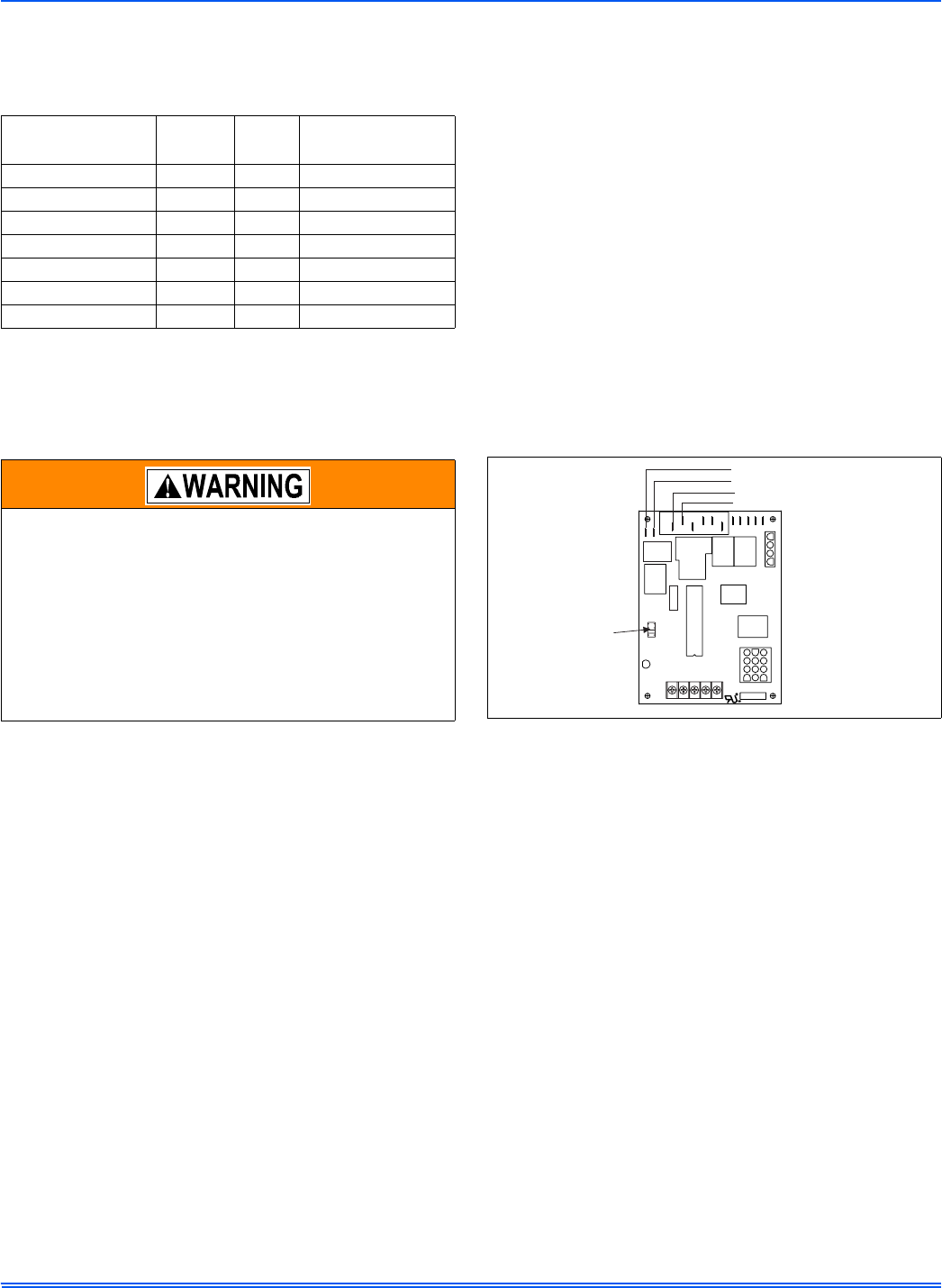

FIGURE 7: Typical Heat/Cool Speed Tap Connections

RED - LOW SPEED

YELLOW - MED. LOW SPEED

BLACK - HIGH SPEED

BLUE -MED. HIGH SPEED

NEUTRALS

HI COOL

HEAT

EAC

L1

XFMR

HUM

PARK

PARK

Y/Y2

W

R

G

C

FAN OFF

ADJUSTMENT

JUMPER