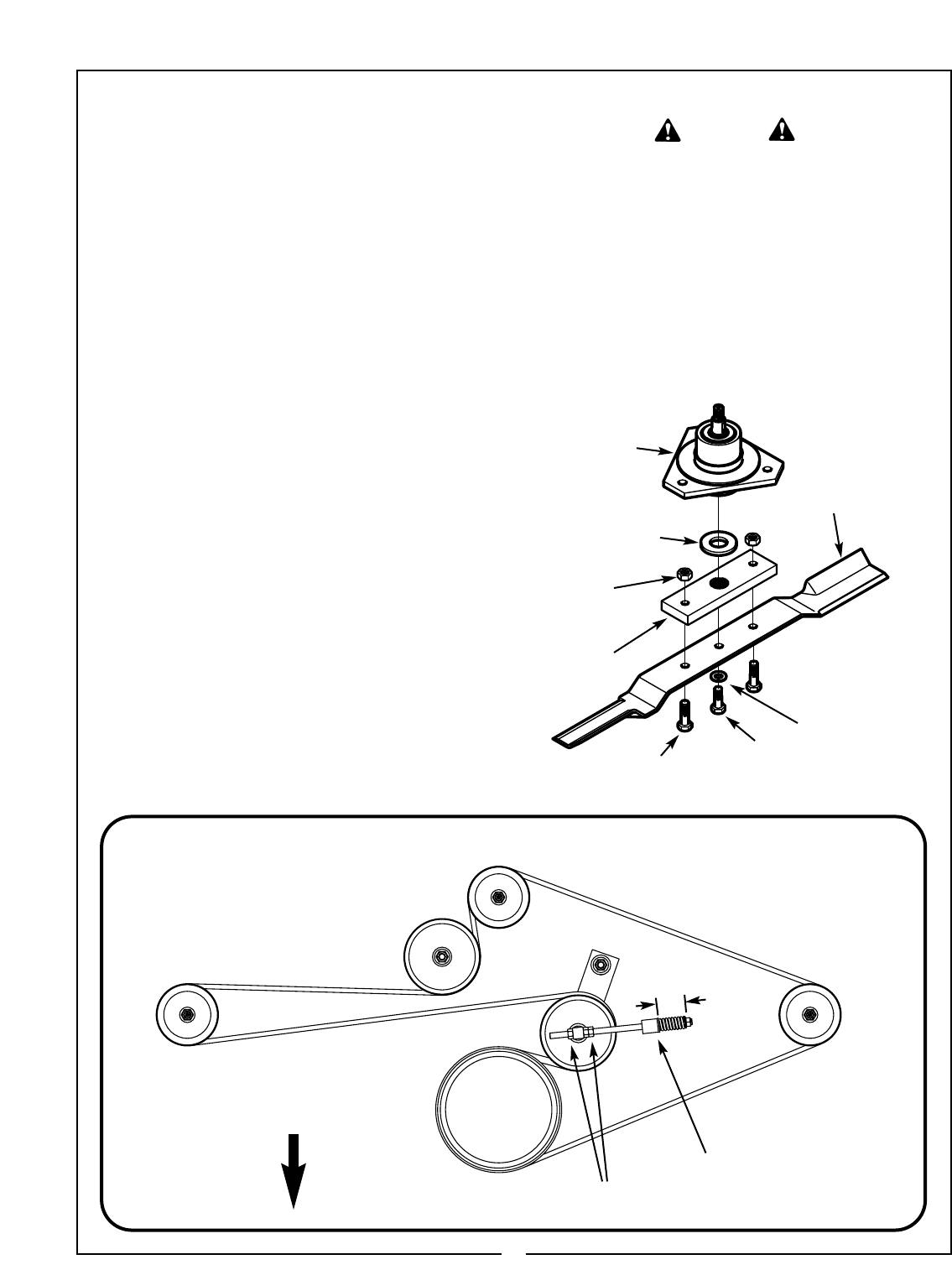

Belt tension should be checked every 40 hours to

get maximum life from drive belt and best perfor-

mance from cutter. Belt tension is adjusted by

increasing or decreasing the length of the spring on

the moveable idler. For proper belt tension the spring

length should be set at 2-7/8”. (Figure 4-2).

To adjust the spring length, loosen or tighten the 1/2”

hex nuts on the spring adjustment rod until the cor-

rect spring length is reached.Use only genuine Bush

Hog replacement parts.

4-4 BELT REPLACEMENT

A. Remove right and left side shields.

B. Relieve spring tension by loosening the two

1/2” hex nuts on the spring adjustment rod.

C. Remove old belt.

D. Install new belt, referring to Figure 4-2. Be

sure that the belt is properly positioned in all sheave

grooves.

E. Adjust tension on the belt by adjusting the

length of the spring on the moveable idler. The cor-

rect spring length is 2-7/8”.

F. Replace right and left side shields.

4-3 BELT ADJUSTMENT

Figure 4-2 Belt Installation Diagram

4-5 BLADE REPLACEMENT

A. Raise cutter using tractor hydraulics and

SECURELY BLOCK INTO POSITION.

B. Set parking brake, turn off tractor and remove key.

C. Remove center bolt securing blade and blade

bar to spindle. Blade and bar will come off as a unit.

Blade bar can then be removed from the blade.

D. Install new blade(s) as shown in Figure 4-3. Be

sure that blades are installed with offset in proper

direction. Tighten retaining bolts to 65 ft./lbs.

WEAR HEAVY WORK GLOVES TO PRO-

TECT HANDS FROM SHARP EDGES.

CAUTION

12

line and shields are securely connected. Make cer-

tain PTO shielding is in good condition.

40 HOURS

7. Spindle Assemblies - Apply 5 shots multi-pur-

pose grease with grease gun. Grease fittings for

spindles can be accessed through holes in the

shields.

Figure 4-3

Spindle Assy.

29” Blade

FRONT

Spring Idler

Blade Bar

1/2 x 1-3/4” Capscrew

1/2 x 1-1/2 UNF

G8 Capscrew

Safety Washer

Locknut

Bearing Washer

2-7/8”

1/2” Hex Nuts