Quick Installation Guide

00825-0100-4716, Rev DA

October 2009

Rosemount 3095 MultiVariable

8

STEP 2 CONTINUED...

Bolting Considerations

If the transmitter installation requires assembly of the process flanges, manifolds, or flange

adapters, follow these assembly guidelines to ensure a tight seal for optimal performance

characteristics of the transmitters. Use only bolts supplied with the transmitter or sold by

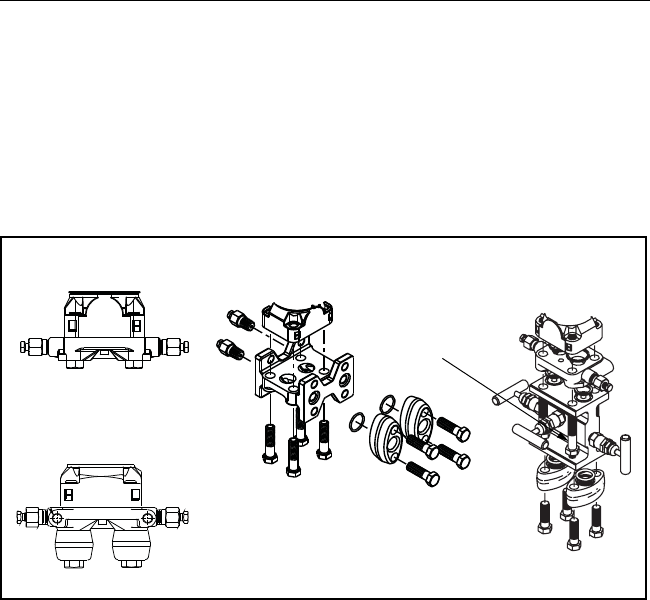

Emerson as spare parts. Figure 6 illustrates common transmitter assemblies with the bolt

length required for proper transmitter assembly.

Figure 6. Common Transmitter Assemblies

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing the

markings on the head of the bolt and referencing Figure 7. If bolt material is not shown in

Figure 7, contact the local Emerson Process Management representative for more

information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel bolts are coated with

a lubricant to ease installation. However, no additional lubricant should be applied when

installing either type of bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern. See Figure 7 for initial

torque value.

4. Torque the bolts to the final torque value using the same crossing pattern. See Figure 7

for final torque value.

5. Verify that the flange bolts are protruding through the isolator plate before applying

pressure.

4 x 1.75-in. (44 mm)

4 x 2.88-in. (73 mm)

A. Transmitter with

Coplanar Flange

B. Transmitter with Coplanar

Flange and Optional

Flange Adapters

C. Transmitter with Traditional

Flange and Optional Flange

Adapters

D. Transmitter with

Coplanar Flange and

Optional Manifold and

Flange Adapters

4 x 1.75-in. (44 mm)

4 x 1.50-in. (38 mm)

4 x 1.75-in. (44 mm)

4 x 2.25-in. (57 mm)