2

A

B

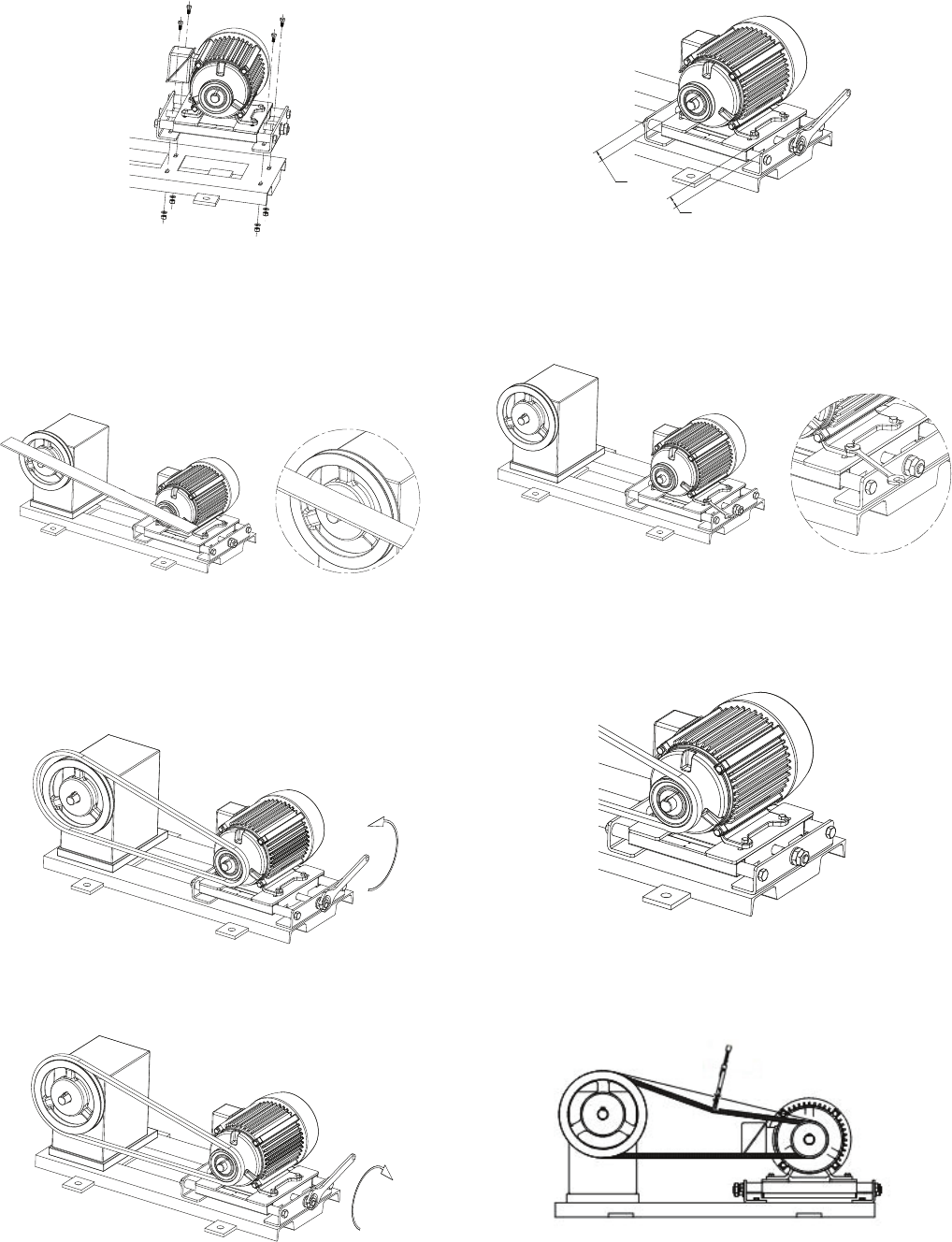

3. Mount the motor base using the recommended grade 5 bolts

(Leave the bolts loose enough to allow the motor base to be

moved to align the sheaves)

4. Set the motor base carriage to the center of the motor base

by adjusting the tension rod until dimension A and B are

equal.

5. Align the motor base to position the sheaves in the proper

location. A straight edge should be used to align the sheave

to be parallel and in the same plane. When this is achieved

the straight edge will be ush to the sides of both sheaves as

shown.

6. Tighten the motor base mounting bolts using the

recommended grade 5 bolts and torques listed in table 1.

7. Rotate the tension rod counterclockwise enough to allow the

belt to slip over the two sheaves by hand. (Prying the belts

over the sheaves with any device can damage the belts or

sheaves)

8. Manually pull the motor base back by hand in the direction

shown and rotate the tension rod clockwise until hand tight.

9. Use a wrench to tighten the tension rod turning clockwise

until the belt feels tight.

10. Check the belt tension using Browning Belt Tension Checker.