Supply System Operation

3A2798D 11

Start and Adjust Ram

1. Set platen configuration based on pail type (see

Adjust Spacers, page 13).

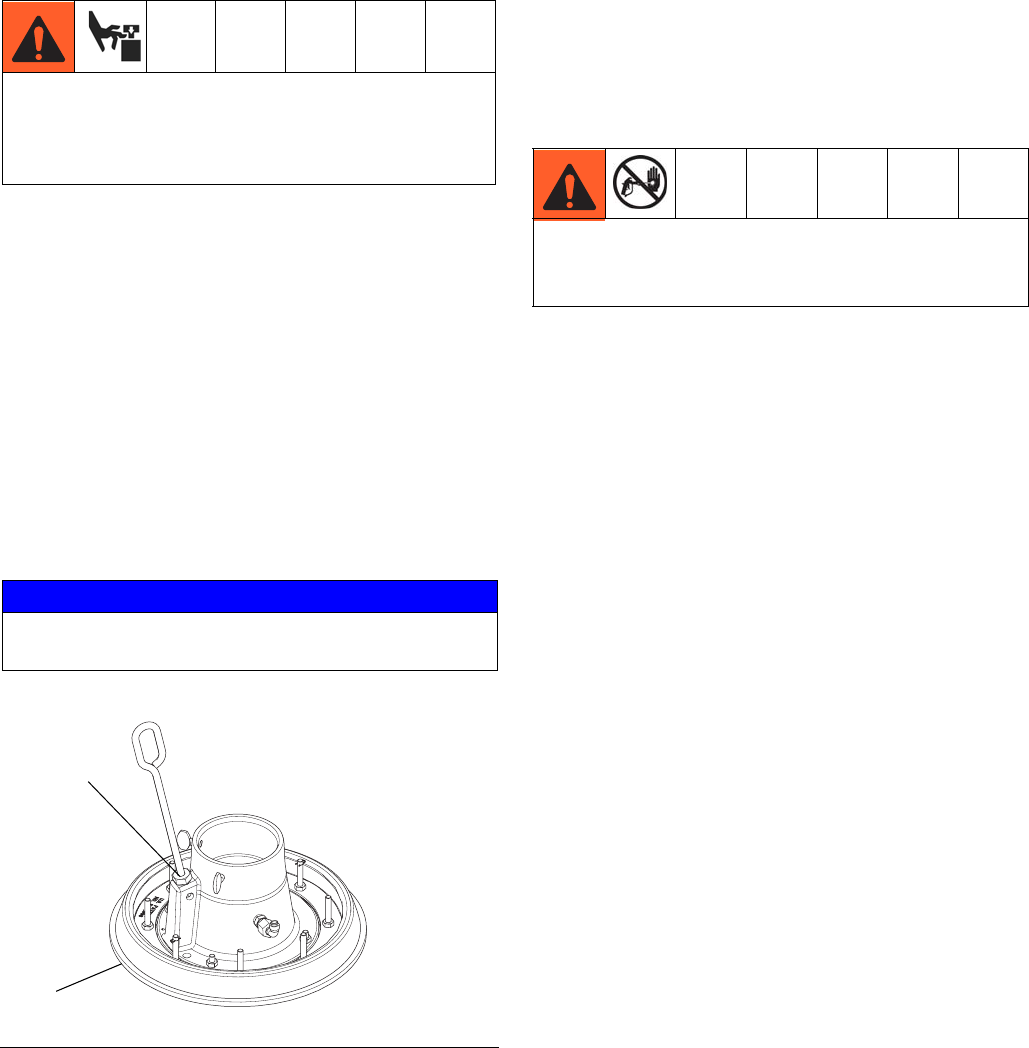

2. Refer to F

IG

. 1 and F

IG

. 2. Close all air regulators

and air valves.

3. Open main air slider valve (BA) and set ram air reg-

ulator (BB) to 45 psi (0.31 MPa, 3.1 bar). Set direc-

tor valve handle (BC) to UP and let the ram rise to

its full height.

4. Remove the drum cover.

5. Put a full drum of fluid on the ram base, slide it back

against the drum stops, and center it under the

platen (D). See F

IG

. 9.

6. Remove bleed stick from platen bleed port (J).

NOTE: Some pails may require the spacer (EG) to

be flipped upside down so the smaller diameter side

is on the bottom. If unable to get ram into the pail,

see Remove and Reinstall Wiper on page 14 to

re-install the spacer upside down.

7. Set the director valve (BC) to DOWN and lower the

ram until fluid appears at the top of the platen bleed

port (J). Adjust ram air regulator (BB) as needed.

Set the director valve (BC) to neutral and close the

platen bleed port (J).

Start and Adjust Pump

1. Start and Adjust Ram, page 11. Keep the director

valve (BC) set to DOWN while pump is operating.

2. Be sure the main air slider valve (BA) is closed.

Then set the ram air regulator (BB) to about

40-45 psi (0.28-3.1 MPa, 2.8-3.1 bar). Set the direc-

tor valve (BC) to DOWN.

3. Open main air slider valve (BA). Use air motor

regulator (BE) to slowly increase pressure until

pump operates at desired flow rate.

NOTE: Increase air pressure to the ram if the pump

does not prime properly with heavier fluids.

Decrease Ram air pressure if fluid is forced out

around the top seal or platen.

Moving parts can pinch or amputate fingers. When

the pump is operating and when raising or lowering

the ram, keep fingers and hands away from the

pump intake, platen, and lip of the drum.

NOTICE

To avoid damage to the platen seals, do not use a

drum that is dented or damaged.

F

IG

. 9

J

D

ti20247b

To prevent equipment rupture, be sure all

components are adequately sized and pressure rated

to meet the system’s requirements.