10 307013

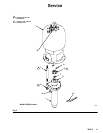

Service

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

Disconnecting the Displacement Pump

1. Flush the pump, if possible. Stop the pump at the

bottom of its stroke. Relieve the pressure.

2. Disconnect the air and fluid hoses. Remove the

pump from its mounting. Note the relative position

of the pump’s fluid outlet (A) to the air motor’s air

inlet (B). See Fig. 2.

3. Screw the coupling nut (32) off of the air motor

piston rod. Be careful not to lose the two couplers

(33) as you lower the nut. Unscrew the tie rod

locknuts (26) from the tie rods (31). Carefully pull

the displacement pump (2) away from the air

motor (1).

4. Refer to the instruction manual 307728 (supplied)

for displacement pump service instructions.

5. Refer to instruction manual 306968 (supplied) for

air motor service instructions.

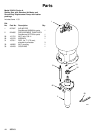

Reconnecting the Displacement Pump

1. Orient the pump’s fluid outlet (A) to the air motor’s

air inlet (B) as was noted in step 2 under Discon-

necting the Displacement Pump. Position the

displacement pump (2) on the tie rods (31).

2. Place the coupling nut (32) on the connecting rod

(T). Insert the couplers (33) into the coupling nut

from the top. Screw the coupling nut (32) onto the

air motor piston rod. Screw the locknuts (26) onto

the tie rods (31) loosely.

3. Mount the pump and reconnect all hoses. Recon-

nect the ground wire if it was disconnected during

repair.

4. Tighten the tie rod locknuts (109) evenly, and

torque to 40–50 ft-lb (54–68 NSm).

5. Tighten the packing nut/wet-cup (S) with the

wrench (28) supplied, so it is just snug - no tighter.

Fill the wet-cup 1/2 full with Graco Throat Seal

Liquid (TSL) or compatible solvent. Start the pump

and run it slowly at about 20 psi (140 kPa, 1.4 bar)

air pressure, to check that it is operating properly.