Repair

3A1211M 13

9. Carefully place the bottom cover (1) on the cylinder

(11), sliding the rod through the bearing. The mani-

fold surfaces of the top and bottom covers must

align.

10. Install the tie bolts (10) hand tight.

11. Install two gaskets (14*) on the manifold (15). Install

the manifold (15). Torque bolts to 95-105 in-lb

(10.7-11.9 N•m).

12. Align the air valve gasket (16*◆) on the manifold,

then attach the air valve.

13. Tighten the tie bolts (10) halfway. Work in a criss-

cross pattern. Continue tightening the bolts in pat-

tern to the torque specified in the following table.

14. Lubricate and install pilot valves (19) in top and bot-

tom cover. Torque to 95-105 in-lb (11-12 N•m).

15. Install the adapter (31) and o-ring (32) in the center

of the top cover (13). Lubricate or apply sealant to

the o-ring as specified in the following table.

Attach the Shroud

1. Inspect the grommets on the top and bottom

shrouds. Order Kit 16G628 (for 3.5 in. air motors) or

Kit 16G385 (for 6.0 in. or 7.5 in. air motors).

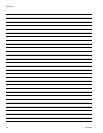

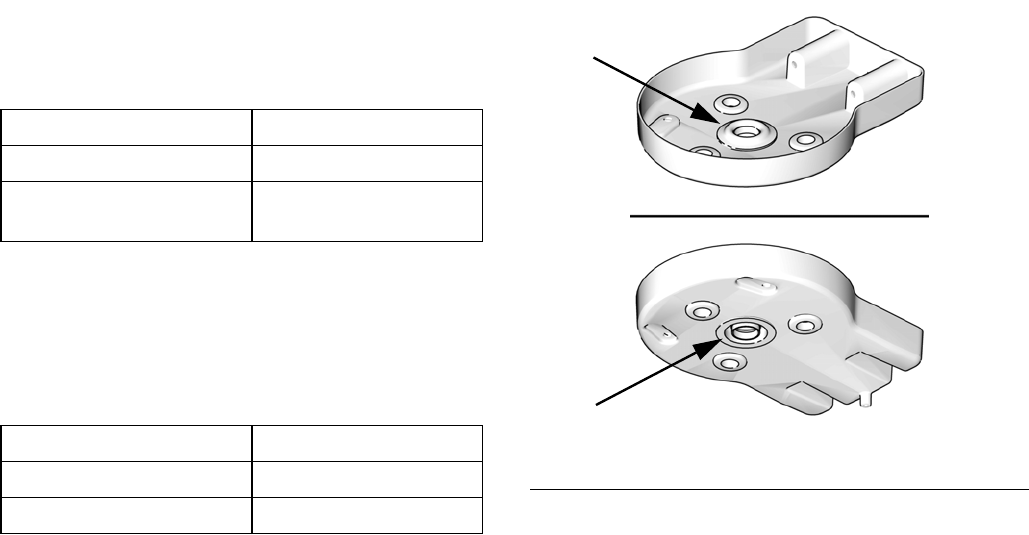

NOTE: The piston rod grommet (21a) must be installed

with the flat side down, as shown. The grommet will be

flush with the shroud when properly installed. It will not

remain in place if installed upside down. The other two

grommets are reversible.

2. If bottom shroud (47) has been removed, slide it up

onto the tie rods (10). Tighten the screws (48).

3. Lower the top shroud (46) over the air motor.

4. Grease and install the o-ring (39), hand screw (40),

and lift ring (41), hand tight.

5. Install the air inlet (43) and exhaust (42) fittings

tightly with a wrench.

Air Motor Torque

24G785

11-13 ft-lb (15-18 N•m)

24G786, 24G787, 24R491,

24R015, and 24W754

25-30 ft-lb (34-40 N•m)

Air Motor O-Ring

24G785, 24G786, 24G787

PTFE; apply sealant.

24R491, 24R015, 24W754

Buna-N; apply lubricant.

FIG. 8. Center Grommet Installation

ti12755a

21a

21a