Setup

10 311882T

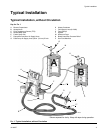

5. Install air line (3/8 in. (76 mm) ID minimum) with

quick disconnect air coupler (52) provided. See F

IG

.

8.

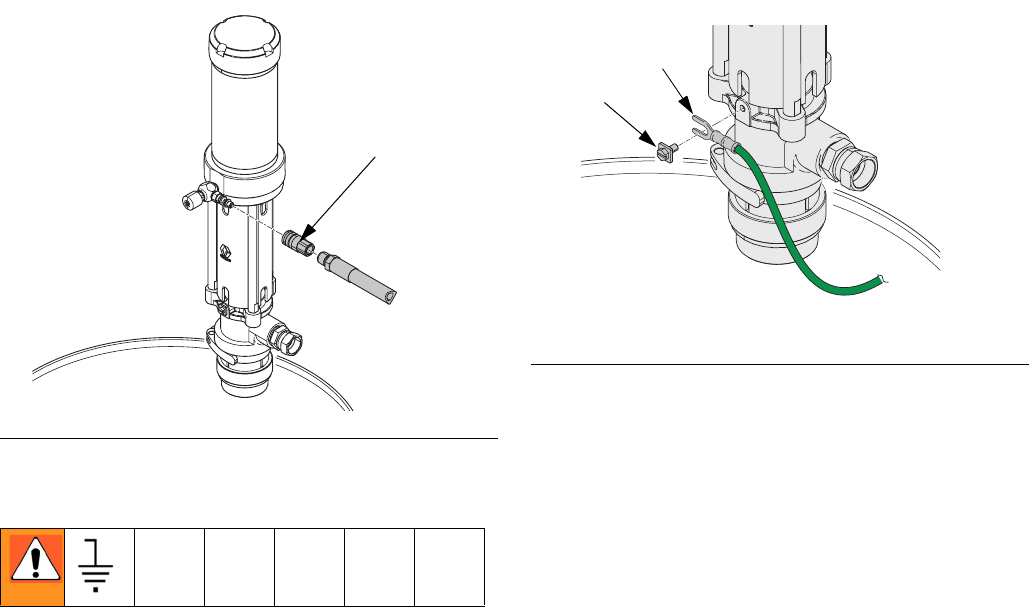

Grounding the System

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of

equipment. Ground all of this equipment.

1. Pump: Connect Ground Wire (Y) to grounding

screw (72) and tighten the screw securely. See F

IG

.

9. Connect the other end of the wire to a true earth

ground. Make certain to comply with all National,

State, and Local Electrical Codes.

2. Air compressor: according to manufacturer’s recom-

mendations.

3. Fluid hoses: use only grounded hoses with a maxi-

mum of 300 ft (91 m) combined hose length to

ensure grounding continuity. Refer to Hose Ground-

ing Continuity.

4. Dispensing valve: grounding is obtained through

connection to a properly grounded fluid hose and

pump.

5. Object being sprayed: according to local code.

6. Fluid supply container: according to local code.

7. All solvent pails used when flushing, according to

local code. Use only metal pails, which are conduc-

tive. Do not place the pail on a non–conductive sur-

face, such as paper or cardboard, which interrupts

the grounding continuity.

8. To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

spray gun/dispensing valve firmly to the side of a

grounded metal pail, then trigger the gun/valve.

F

IG

. 8

52

F

IG

. 9

WLD

Y

72