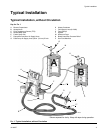

Installation

8 311882T

Installation

System Accessories

To ensure maximum pump performance, be sure that all

accessories used are properly sized to meet your sys-

tem’s requirements. See Accessories, page 20.

Air Line Accessories

Install the following accessories in the order shown in

the Typical Installation for Lubrication Applications,

using adapters as necessary:

An air line lubricator (B) provides automatic air motor

lubrication.

A bleed-type master air valve (D) is required in your

system to relieve air trapped between it and the air

motor when the valve is closed (see the WARNING on

left). Be sure the bleed valve is easily accessible from

the pump, and is located downstream from the air regu-

lator.

An air line filter (C) to remove harmful dirt and moisture

from the compressed air supply.

A second bleed-type air valve (D) isolates the air line

accessories for servicing. Locate upstream from all

other air line accessories.

Fluid Line Accessories

A fluid drain valve (E) is required in your system to

relieve fluid pressure in the hose and gun (see the

WARNING on left). Install the drain valve so that it

points down and the handle points up when the valve is

opened.

A bleed-type master air valve (D) and a fluid drain

valve (E) are required in your system, to help reduce

the risk of serious injury, including splashing fluid in

the eyes or on the skin, and injury from moving parts

when you are adjusting or repairing the pump.

The bleed-type master air valve (D) relieves air

trapped between this valve and the pump after the

pump is shut off. Trapped air can cause the pump to

cycle unexpectedly and result in serious injury,

including amputation. Install the valve close to the

pump.

The fluid drain valve (E) helps relieve pressure in the

displacement pump, hose, and dispensing valve

when shutting off the pump. Actuating the dispensing

valve to relieve pressure may not be sufficient, espe-

cially if there is a clog in the hose or the dispensing

valve.