Installation

308778L 5

Installation

Dust and Foreign Matter

Avoid having dust or foreign matter enter the flow meter

by taking the following precautions:

• Thoroughly flush the fluid supply lines before install-

ing the flow meter.

• When installing fittings, make sure that no sealing

tape overlaps into the inside of the pipe.

• Install a 100 mesh fluid filter upstream of the flow

meter.

Installing the Flow Meter

• Flow volume can only be measured at the location

where the flow meter is installed.

• The Fluid Flow Meters are intrinsically safe for Class

I; Division 1; Group D hazardous indoor (NEMA 1)

locations when installed with an intrinsically safe

power device and wiring.

Refer to ANSI standards ISA-RP12.6, NEC Article

504 and the Canadian Electrical Code Appendix F.

• Do not use more than 200 ft. (61 m) of cable.

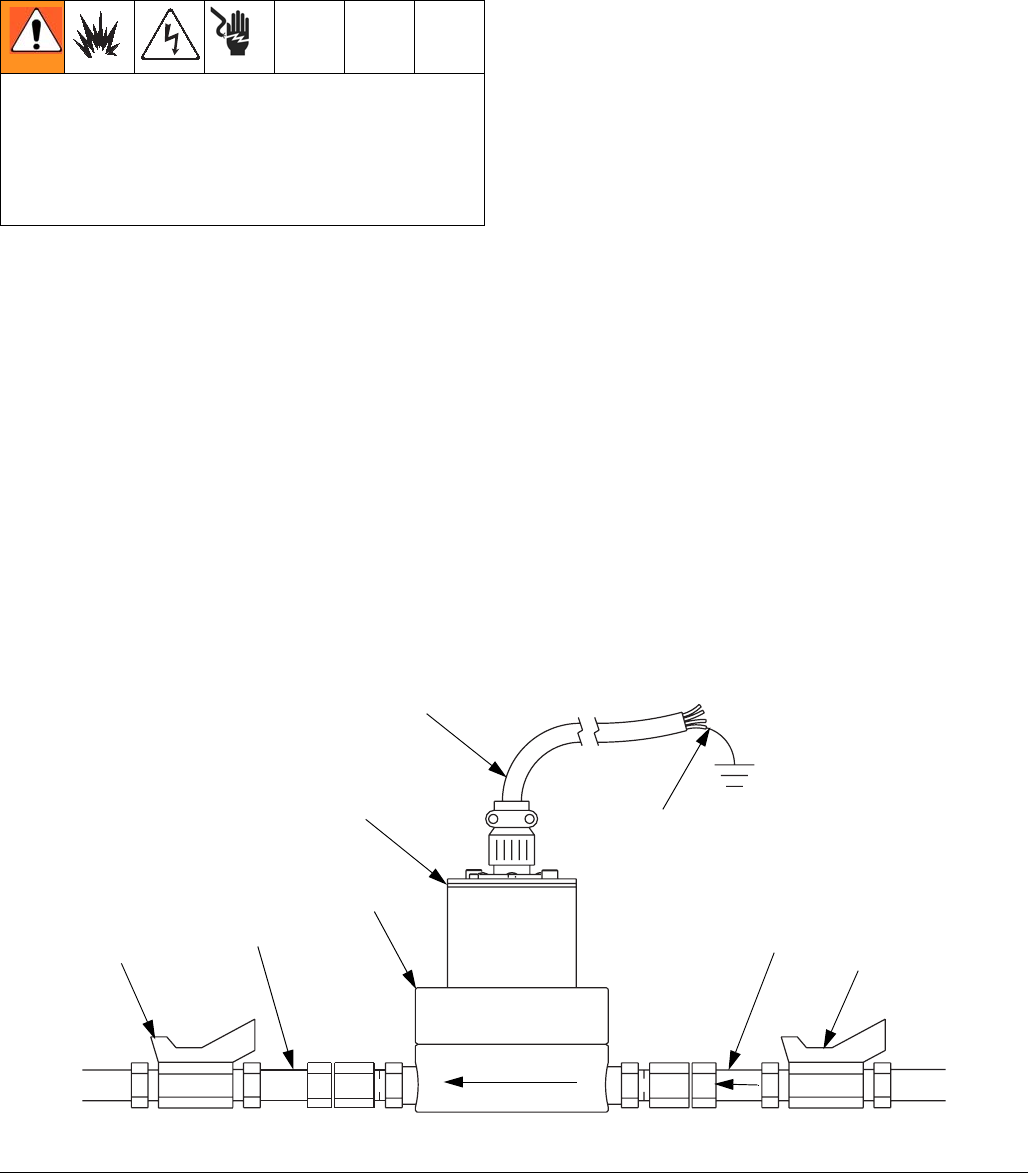

• Refer to F

IG. 1 to locate and install the flow meter,

connectors, and fluid shutoff valves. Install a check

valve to prevent backflow. The arrows on the flow

meter and check valve show the direction of fluid

flow.

• The shutoff valves allow you to isolate the meter for

service.

• Refer to the Technical Data and Dimensions

Drawings for dimension, inlet/outlet size, tempera-

ture and other specifications.

• All electrical equipment must only be installed by

a qualified electrician.

• Understand and follow your local code and safety

regulations for hazardous location wiring of intrin-

sically safe circuits.

FIG. 1: Typical Installation

7379A

Cable

Electronic Sensor Device

Flow Meter

Fluid LineFluid Shutoff Valve

on outlet side

Ground Sheath

Check Valve Fluid Shutoff Valve

on outlet side