Repair

16 312375J

23. Partially thread wet cup (9) into cartridge (3) to hold

packings in place during installation. Install new car-

tridge o-ring (4) on cartridge (3). Apply thread lubri-

cant to cartridge (3) and carefully slide down over

displacement rod and into outlet housing (2). Torque

cartridge to the following torque. Be careful not to

damage throat packings on leading edge of rod.

24. Use packing nut wrench (supplied) to tighten wet

cup (9) to specified torque; refer to the following

table.

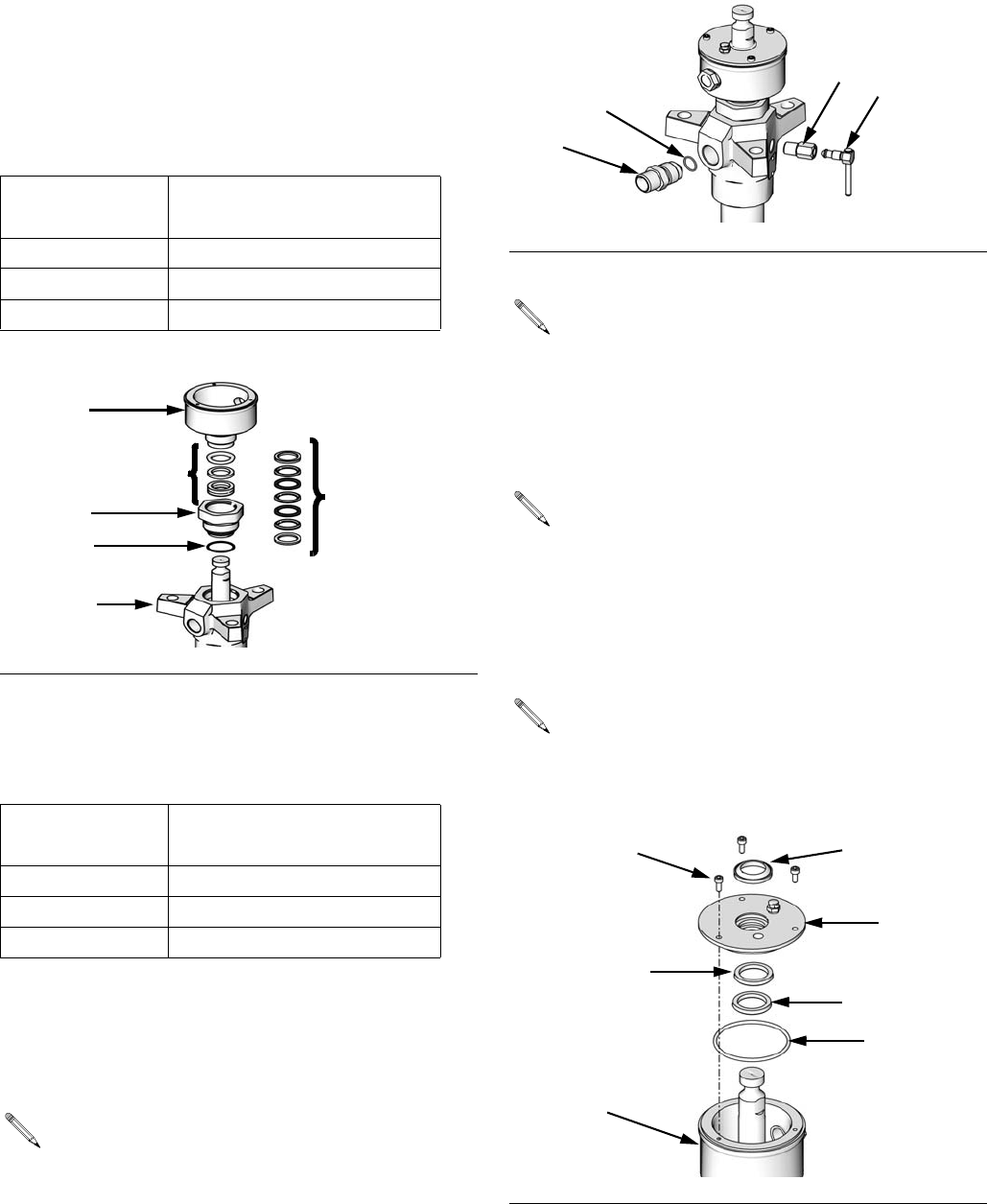

25. Lubricate the threads of the bleeder valve plug (40).

The plug has two sets of threads. Be sure to screw

the plug completely into the valve body (39). Torque

the plug to 9-11 ft-lbs (12-15 N•m).

26. Install new o-ring (11), wet cup wiper (15), seal (16),

and snap ring (61) into wet cup cover (10). See F

IG.

31.

27. Carefully slide wet cup cover (10) over displacement

rod. Line up holes in cover and wet cup. Insert

screws (14). Use a hex head screwdriver to tighten

screws. See F

IG. 31.

Displacement

Pump Torque

60cc and 100cc 90-130 ft-lbs (122-176 N•m)

200cc and 250cc 130-190 ft-lbs (176-257 N•m)

500cc 150-261 ft-lbs (203-355 N•m)

F

IG. 29

Displacement

Pump Torque

60cc and 100cc 28-44 ft-lbs (38-59 N•m)

200cc and 250cc 95-115 ft-lbs (128-155 N•m)

500cc 95-115 ft-lbs (128-155 N•m)

Some models include an outlet nipple (43) and

o-ring (44). It is not ordinarily necessary to remove

these parts. However, if they were replaced

because of damage, lubricate o-ring and place it on

nipple. Screw nipple into outlet housing (2). Torque

to 44-62 ft-lbs (60-84 N•m).

ti10576a

4

3

2

P

P

(Severe Duty)

(MaxLife)

9

FIG. 30

Steps 26-27 apply only to displacement pumps

with enclosed wet cups.

The snap ring (61) is applicable only to 60cc and

100cc displacement pumps.

Use caution when sliding wet cup cover (10) over

displacement rod (1) to avoid damaging seals (15,

16).

F

IG. 31

ti10585a

39

40

44

43

ti10561a

10

61

11

16

14

1, 9

15