22

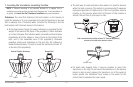

Transom Mount - DualBeam PLUS™

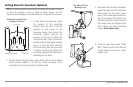

NOTE: The deeper the transducer is in the water, the more likely that a rooster

tail of spray will be generated at high speeds, so make sure that the transducer

is as high as it can be and still be submerged in the water.

If you are still not getting good high speed readings, you may need

to disassemble the transducer mounting assembly and re-position

the ratchets.

If you do change the transducer position, re-trace the position of the

mounting bracket before proceeding.

NOTE: It is often necessary to make several incremental transducer adjustments

before optimum high speed performance is achieved. Due to the wide variety of

boat hulls, however, it is not always possible to obtain high speed depth

readings.

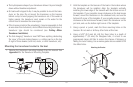

6. Once you have reached a consistently good sonar signal at the

desired speeds, you are ready to lock down the transducer settings.

Force the pivot to the Up position to gain access to the mounting

screws, then re-align the mounting bracket against the transom of

the boat to match the traced silhouette. Check the bracket position

with the level again to make sure it is still level, then mark the third

mounting hole using a pencil or marker. Unscrew and remove the

mounting screws and the transducer assembly and set aside.

7. Drill the third mounting hole, using a 5/32” drill bit. Use a marine-

grade silicone sealant to fill all three drilled mounting holes,

especially if the holes penetrated the transom wall.

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce

the chance of chipping or flaking the outer coating.

8. Re-position the transducer assembly

against the transom of the boat, then

hand-install all three screws. Make

sure that the transducer location and

the pivot angle have not changed,

then fully tighten all three mounting

screws. Snap the pivot back down. If

you have performed the preceding

procedures correctly, the transducer

should be level and at the right

height for optimal operation.

Fully Tighten All Three

Mounting Screws