46

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

Kirby Morgan 77

3.6.3 Check Communications

Check the communications system for proper opera-

tion. Put the helmet on and talk to an assistant on the

amplifier. If you are by yourself, with the helmet off

take the helmet near the amplifier and tap on each

earphone and the microphone, listening to the taps

on the amplifier/speaker. Talk into the amplifier/

speaker feeling the vibration on each earphone and

the microphone with your fingertips. Check the fit

and tightness of the comm module mount nut.

3.6.4 One Way Valve Check

The one way valve must be tested daily, prior to

commencement of diving operations.

1) Prior to attaching (or pressuring up) the umbilical,

close the emergency valve knob, attach and pressure

up the emergency hose. Shut off the defogger control

knob and screw in the adjustment knob on the regula-

tor all the way.

2) With the emergency hose pressurized, turn on the

emergency valve knob. If any gas escapes out the end

of the adapter, the one way valve is faulty and must

be rebuilt or replaced. A one way valve repair kit is

available to rebuild these valves (Part # 525-330).

10) Check the screws on the port retainer . They must

be adjusted to the proper torque setting specifications

noted in Appendix 1 of this manual. Binder head

screws are used in this application for their self lock-

ing characteristics.

3.6 Preparing the Helmet for Diving

3.6.1 Clean Face Port

Thoroughly clean the face port with a soft cloth and

a mild liquid soap solution. DO NOT USE ANY

AEROSOL SPRAYS ON THE POLYCARBONATE

PORT!

3.6.2 Check Moving Parts

Check all moving parts, such as the regulator adjust-

ment knob, the defogger control knob, emergency

(EGS) knob, and the nose block device knob and

all locking collar parts to ensure smooth and proper

operation.

All parts on Kirby Morgan diving helmets

must be adjusted to their proper torque

specifications. See Appendix 1 for a

complete listing of torque specifications

for each part. Failure to adjust parts to

the recommended specifications could

lead to helmet failure and accidents. This

could be fatal.

WARNING

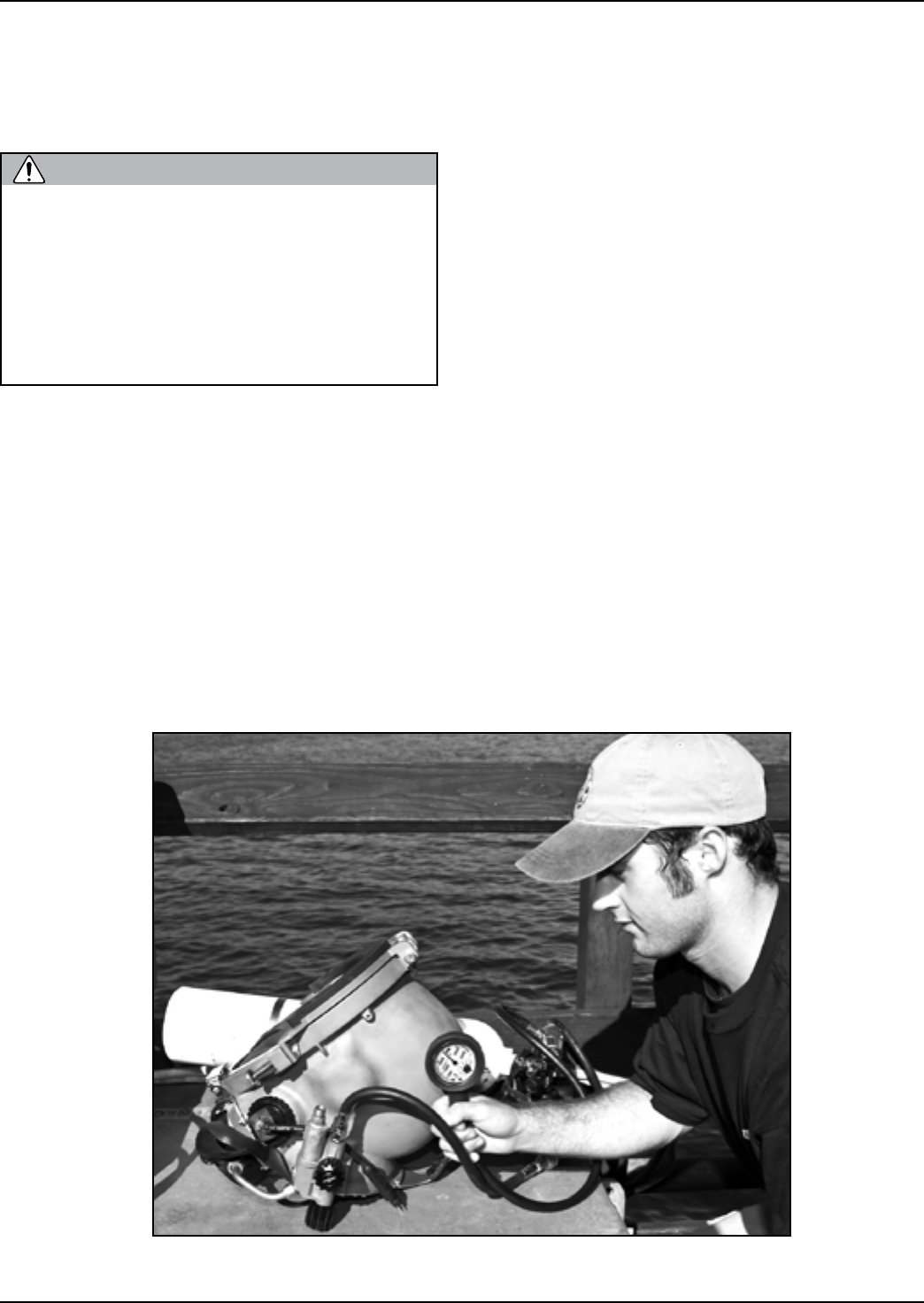

You can test the one way valve by connecting the bailout bottle to the emergency valve and pressurizing the

sideblock. There must be no gas leakage through the one way valve.