PROPELLER INSTALLATION INSTRUCTIONS

Products of Mercury Marine

Mercury, Mercury Marine, MerCruiser, Mercury MerCruiser, Mercury Racing, MotorGuide, Mercury Precision Parts,

Mercury Propellers, Mariner, Quicksilver, #1 On The Water, Alpha, Bravo One, Bravo Two, Bravo Three, Pro Max,

OptiMax, Sport-Jet, K-Planes, MerCathode, RideGuide, SmartCraft, Zero Effort, VesselView, Zeus, Axius, Total

Command, Skyhook, SeaCore, M with Waves logo, Mercury with Waves logo, and SmartCraft logo are all trademarks

or registered trademarks of Brunswick Corporation. Mercury Product Protection logo is a registered service mark of

Brunswick Corporation.

W6250 Pioneer Road

Fond du Lac, WI 54936-1939

90-830296005 FEBRUARY 2010 Page 7 / 7

Propeller Basics

Consult the engine's Owners, Operation and Maintenance Manual for the recommended wide‑open throttle (WOT) operating

range of the engine.

Select a propeller that allows the engine to operate within the WOT RPM operating range.

IMPORTANT: Always perform WOT RPM tests with the boat in its normal configuration; i.e. fuel load, passenger load, equipment

load, skiers, etc.

Use the following information to help select the proper propeller for the vessel:

• Adding 25 mm (1 in.) of propeller pitch will reduce the WOT RPM by 150 to 200 RPM.

• Subtracting 25 mm (1 in.) of propeller pitch will increase the WOT RPM by 150 to 200 RPM.

• Switching from a three blade to a four blade propeller with the same pitch generally reduces WOT RPM by 50 to 100 RPM.

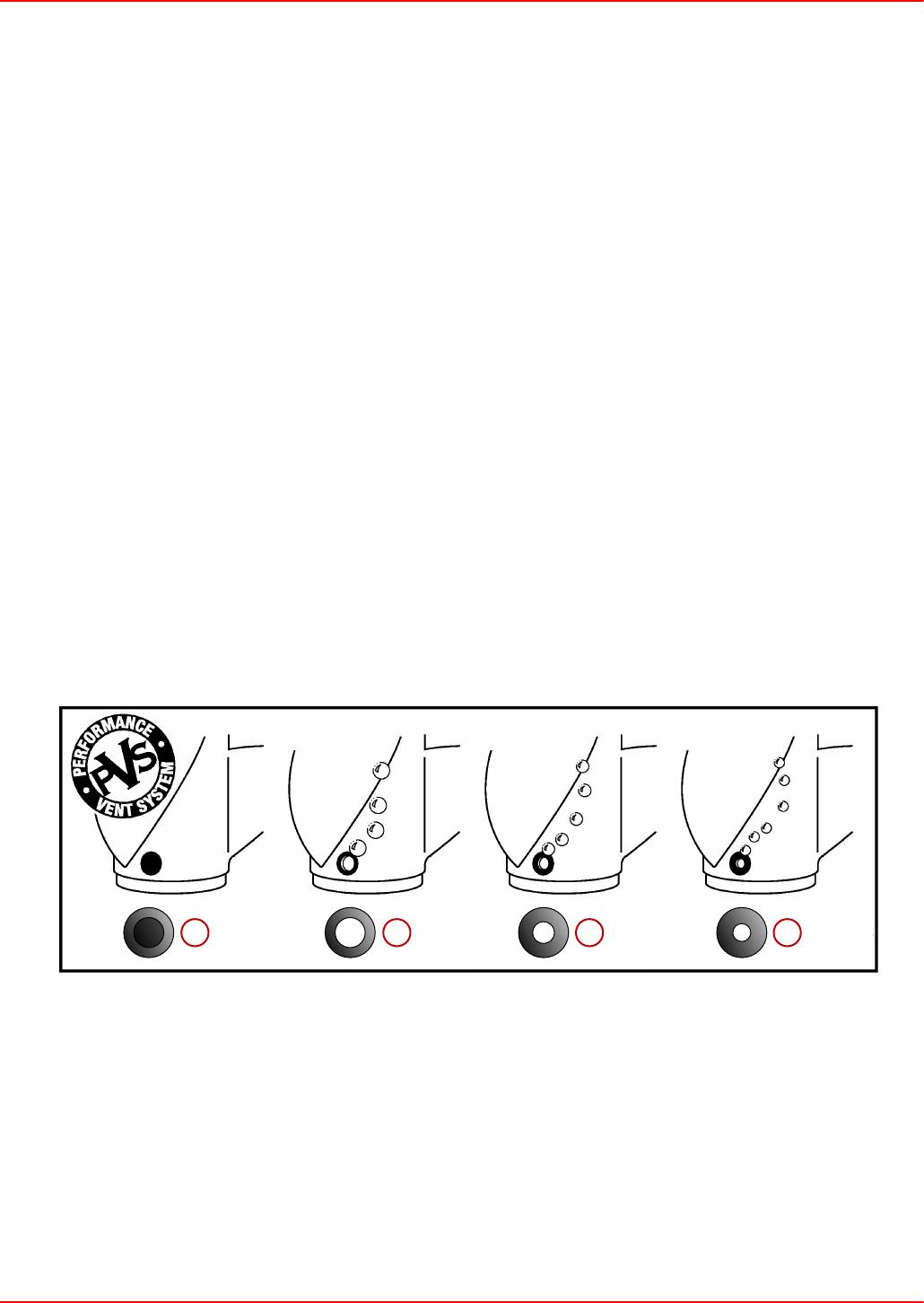

Performance Vent System

The performance vent system (PVS) was created to help our customers optimize Mercury Propellers on their personal boat and

unique boating conditions. PVS allows the boater to custom tune the venting of the propeller blades to dial in the perfect

acceleration and cruising performance.

On acceleration, exhaust is drawn out of the vent hole located behind each propeller blade. When the next propeller blade strikes

this aerated water, less force is required to push through the aerated water versus solid water. This allows the engine RPM to

rise more rapidly. Once on plane speed is reached, water flowing over the vent holes seal the exhaust gas in the hub, allowing

the propeller to again operate in solid nonaerated water. By varying the size of the exhaust vent hole, the rate at which the engine

RPM rises can now be controlled.

Laser II, Trophy Plus, and Tempest Plus propellers are shipped with medium PVS vent plugs; and Mirage Plus, Offshore,

Revolution 4, and HighFive propellers are shipped with solid PVS vent plugs offering all‑around performance for most boating

situations.

Acceleration Problem/Solution

1. Slow/sluggish acceleration to plane (engine unable to push solid water away quickly).

• Solution: Increase ventilation by using a plug with larger holes.

2. Over ventilation ‑ the load on the propeller is significantly reduced by the mixing of exhaust into the water stream causing

an engine overrevving condition before the vessel is on plane.

• Solution: Decrease ventilation by using a plug with a smaller hole or use a solid plug.

a - Solid plug

b - Large ‑ 12 mm (0.470 in.)

c - Medium ‑ 9 mm (0.350 in.)

d - Small ‑ 7 mm (0.280 in.)

13391

a

b

c

d