MQ41TDH TRASH PUMP — PARTS & OPERATION MANUAL — REV. #3 (04/02/07) — PAGE 13

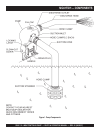

MQ41TDH — GENERAL INFORMATION

The MQ41TDH Trash Pump is a self-priming centrifugal trash

pump powered by a 15 horsepower air-cooled four stroke HATZ

diesel engine. Both the intake (suction) and discharge ports on

the MQ41TDH incorporate a 4-inch diameter opening, which

allows the pump to pump at a rate of approximately 611 gpm or

2,313 lpm.

Trash Pump

Trash pumps derive their name from their ability to handle a

greater amount of debris and solids than standard centrifugal

pumps. These pumps generally handle solids up to 1/2 the size

of the discharge opening making them less likely to clog. Also

trash pumps are capable of handling water with 25% solids by

weight.

The advantage of using a trash pump is that it can be quickly

and easily disassembled in the field to remove debris in the

event the pump becomes clogged.

Suction Lift

This pump is intended to be used for dewatering applications

and is capable of suction lifts up to 25 feet at sea level. For

optimal suction lift performance keep the suction hose or line as

short as possible. In general always put the pump as close to the

water as possible.

Pump Support

The pump should always be placed on solid stationary ground

in a level position. To prevent the trailer from tipping, place blocks

under the trailer's bumper. In addition, place chock blocks behined

each wheel to prevent the trailer from rolling.

NEVER place the pump on

soft soil

. The suction hose or pipe

connection should always be checked for tightness and leaks. A

small suction leak in the hose or fittings could prevent the pump

from priming.

Elevation

Elevations over 3,000 feet will effect the performance of the

pump. Due to less atmospheric pressure at higher altitudes,

pumps DO NOT have the priming ability that they have at sea

level.

A general rule of thumb is that for every 1,000 feet of elevation

above sea level a pump will lose one foot of priming ability.

For example, in Flagstaff, Arizona where the elevation is

approximately 7,000 feet, the pump would have a suction lift of

only 18 feet rather than the 25 feet at sea level.

Pump Clean-out

The clean-out cover on the MQ41TDH has been design for easy

removal that allows for easy access to the volute and impeller

for cleaning and servicing.

Spark Arresters

State Health Safety Codes and Public Resources Codes specify

that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester

is a device designed to prevent accidental discharge of sparks

or flames from the engine exhaust. Spark arresters are qualified

and rated by the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters,

consult the engine distributor or the

local Health and Safety

Administrator.

Mechanical Seal Lubrication

The pump uses a water-cooled mechanical seal to prevent water

from seeping into the engine. The passage of water through the

pump casing lubricates the seal and prevents it from overheating.

Never operate the pump without water in the casing as this will

cause the seal to fail.

Engine Safety

Internal combustion engines present special hazards during

operation and fueling! Failure to follow the safety guidelines

described in the Rules for Safe Operation section of this manual

and the Hatz Engine Operator's Manual could result in severe

injury or death.

Accessories

Multiquip offers a complete line of fittings, hoses, and clamps to

properly connect the pump to match various job conditions. Refer

to the part list in section 2 of this manual for a complete list of

accessories

.