3

SYSTEM WIRING

To prevent electrical shock and/or equipment

damage, disconnect electrical power to system at

main fuse or circuit breaker box until installation

is complete.

All wiring should be installed in accordance with local

and national electrical codes and ordinances.

Always check that the electrical power supply used

agrees with the voltage and frequency shown on the

gas control.

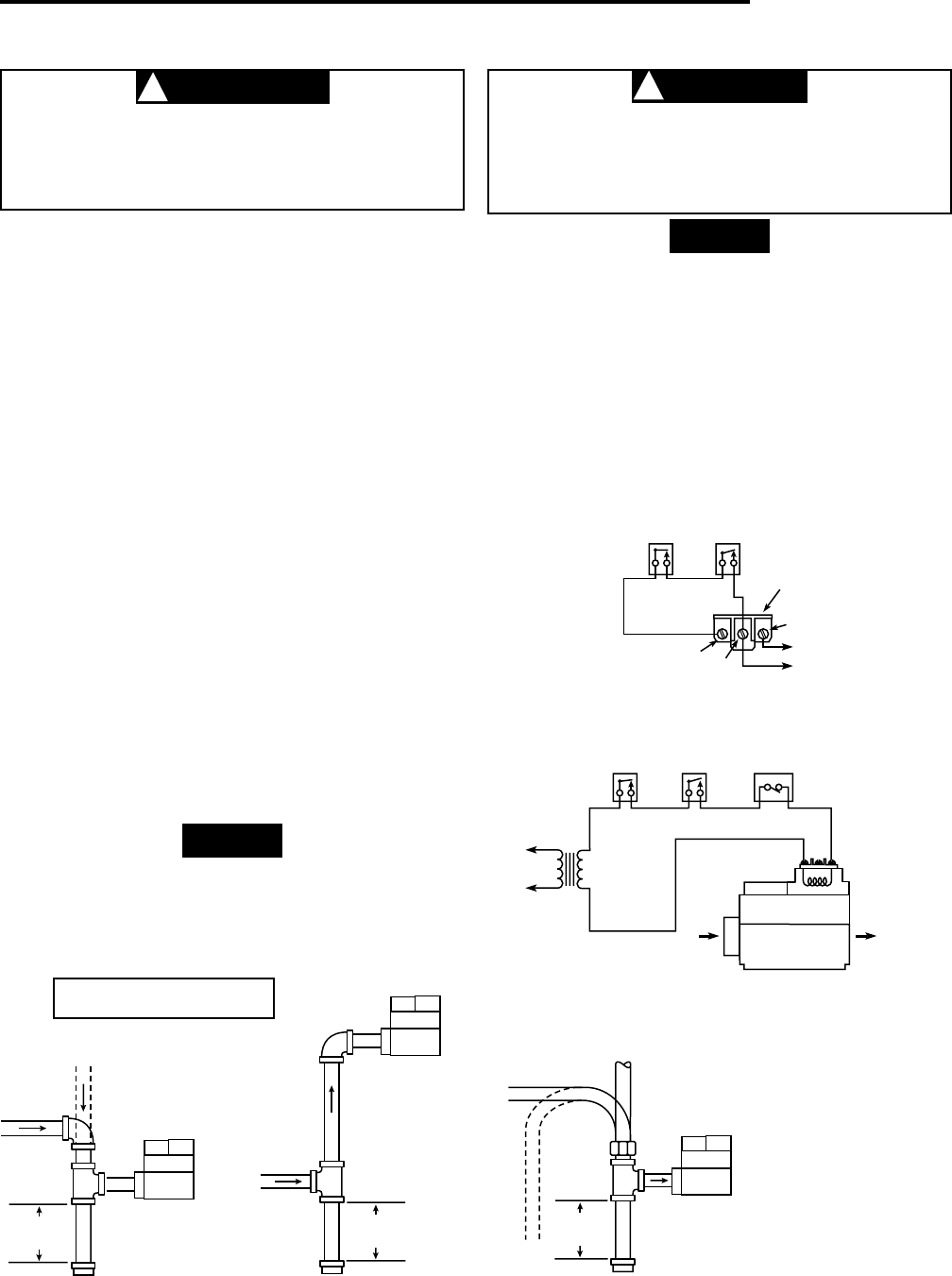

These typical wiring diagrams (figs. 2 and 3) show only the

terminal identification and wiring hook up. Always refer to

wiring instructions provided by equipment manufacturer

for system hook-up and operation.

INSTALLATION

MAIN PIPING CONNECTIONS

Failure to turn off electric or main gas supply to

heating system could cause personal injury and/

or property damage by shock, gas suffocation,

fire, and/or explosion.

1. Turn off electrical power to the system at the fuse box

or circuit breaker. Also turn off the main gas supply.

2. If replacing an existing valve, disconnect all plumbing

and electrical connections from the old control.

3. The control may be installed in any orientation except

upside down. The arrow on the valve indicates the

direction of gas flow through the control.

4. You should use new pipe that is properly chamfered,

reamed, and free of burrs and chips. If you are using

old pipe, be sure it is clean and free of rust, scale,

burrs, chips, and old pipe joint compound.

5. Apply pipe joint compound (pipe dope) or teflon tape

that is approved for all gases, only to the male

threads of the pipe joints. DO NOT apply com-

pound or teflon tape to the first two threads (see fig. 1

for typical piping connections).

6. If you are using a vise or open-end wrench to hold the

valve while installing piping, do not tighten exces-

sively, as this may damage the valve.

7. See SYSTEM WIRING when making electrical con-

nections. After all gas and electrical connections are

completed, turn gas on and check for gas leaks with

leak detection solution or soap suds. Bubbles forming

indicate a leak. SHUT OFF GAS AND FIX ALL

LEAKS IMMEDIATELY.

All piping must comply with local codes, ordinances,

and/or national fuel gas codes.

Thermostat

24 VAC

Gas

Valve

High

Limit

36C21

Valve

Automatic

Pilot

Figure 3. Wiring for 36C21 and 36C21A Models

NOTE

WARNING

!

CAUTION

!

NOTE

Piped Gas

Supply

Piped Gas

Supply

Tubing Gas

Supply

NOTE: ALWAYS INCLUDE A

DRIP LEG IN PIPING

Figure 1. Typical gas valve piping

Horizontal

Drop

Gas Valve

3 in.

minimum

Gas Valve

Riser

3 in.

minimum

Drop

Horizontal

Riser

Gas Valve

3 in.

minimum

High

Limit

To Pilot

Generator

TH

TH-TR

TR

Thermostat

Gas Valve

Terminal Panel

ALL WIRING

MUST BE

N.E.C. CLASS 1

Figure 2. Wiring for 36C21U