Mounting & Adjusting the Bracket

CAUTION: Do not position the transducer deeper in the water

than necessary to avoid increasing drag, spray, and water noise

and reducing boat speed.

CAUTION: The stainless steel bracket must be isolated from a

metal hull to prevent electrolytic corrosion. If no shim is being

used, place non-metal insulating washers between the bracket

and the metal hull.

1. Apply marine sealant to the threads of four of the hex-washer-

head screws to prevent water seepage into the transom. Being

sure any shim(s) is in place, screw the bracket to the hull using

a socket wrench (see Figure 4). Do not tighten the screws

completely at this time.

2. Reinstall the transducer. While holding the transducer assembly

against the bracket, insert the hinge pin through the upper hole

in the bracket and the support. Slide the spacer onto the pin

and push it through the remaining hole in the support and the

bracket. Reattach the safety ring.

3. Slide a washer onto the locking pin. Push it through the lower

hole in the bracket, slide it along the channel in the support, and

through the second hole in the bracket. Slide the second

washer onto the free end of the pin and reattach the safety ring.

4. With the transducer in the operational position, Use a straight edge

to sight the underside of the transducer relative to the underside of

the hull (see Figure 5). The trailing edge of the transducer should

be 1–6mm (1/16–1/4") below the leading edge.

5. Using the vertical adjustment space in the bracket slots, slide the

assembly up or down until the bottom inside corner of the

transducer projections 0–3mm (0–1/8") below the bottom of the

hull (see Figure 1). When you are satisfied with the position of the

transducer, tighten the four bracket screws. For clear access to

the screws, remove the transducer assembly from the bracket

(see Figure 4). When reattaching, be sure to include the spacer.

Testing on the Water

1. Test the transducer at 200kHz with the engine off.

2. Become familiar with your echosounder’s performance at a

speed of 4kn (5 MPH).

3. Gradually increase the boat speed and observe the gradual

decline of performance due to turbulent water flowing over the

transducer’s active surface.

NOTE: As the speed increases the performance at 50kHz will

deteriorate more rapidly because more acoustic noise is

generated at low frequencies.

4. If the decline in performance is sudden (not gradual), identify

the boat speed at which the onset occurred. Return the boat to

this speed, then gradually increase speed while making

moderate turns in both directions.

5. If the performance improves while turning to the side on which the

transducer is installed, it’s position probably needs adjustment.

The transducer is probably in turbulent or aerated water.

To improve performance, try the following, one at a time, in the

order given.

A. Increase the transducer’s angle in the water. Review “Shims”

and see Figure 5.

B. Move the transducer deeper into the water in increments of

3mm (1/8") (see Figure 1).

C.Move the transducer closer to the centerline of the boat.

Fill unused screw holes with marine sealant.

Stabilizing the Bracket

1. Prevent the bracket from moving out of position with the

remaining hex-washer-head screw. Drill the hole for the

stabilizing screw through the center hole of the bracket, any

shim(s), and the hull (see Figure 6).

3

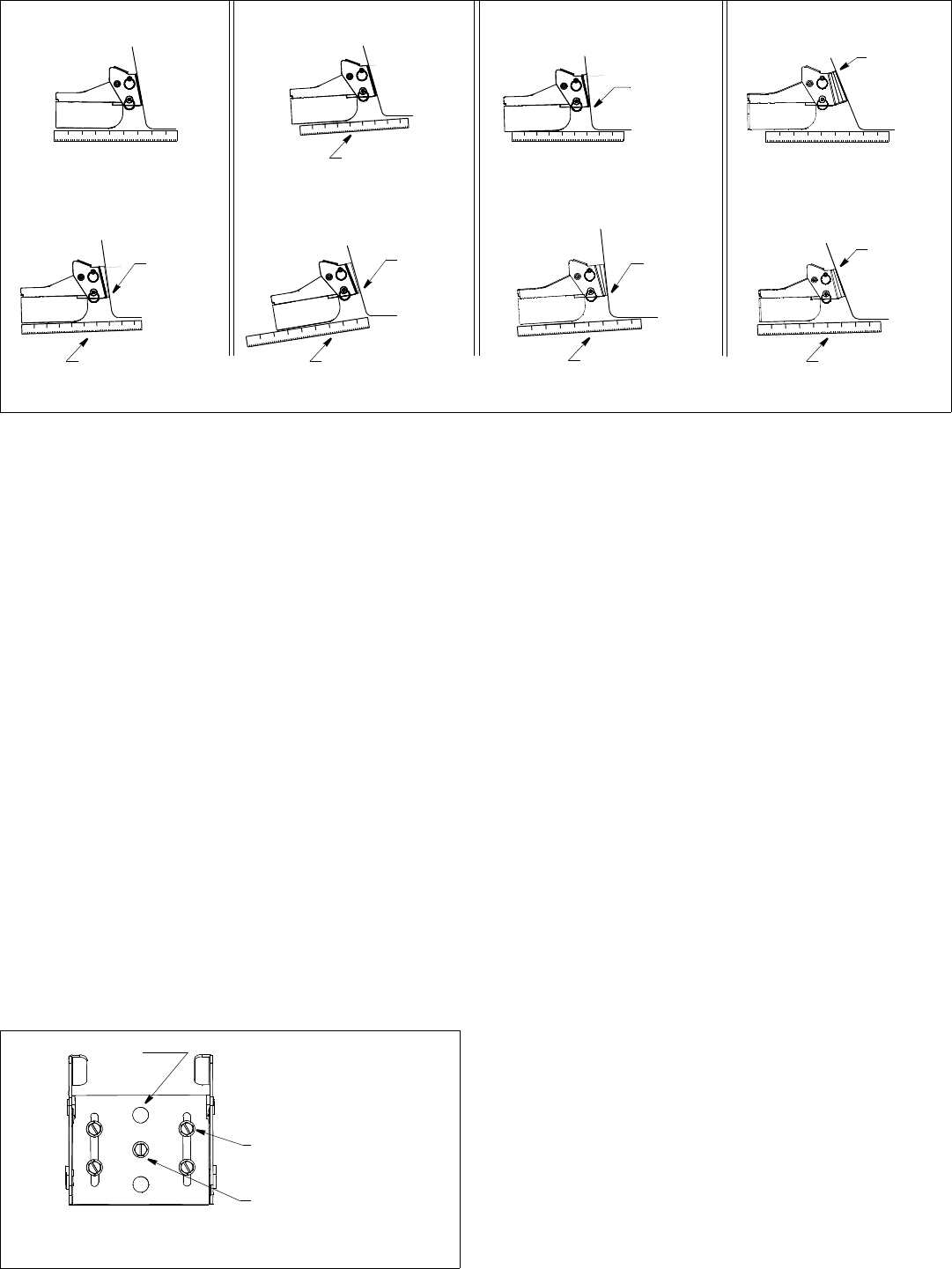

12° transom angle

13° angle

Figure 5. Adjusting the transducer angle

21° transom angle9° transom angle

parallel

slight angle

one

shim

three shims

taper down

slight angle

parallel

one shim

taper down

parallel

May improve operation

above 20kn (23MPH)

May improve operation

above 20kn (23MPH)

slight angle

two shims

taper down

slight angle

May improve operation

above 20kn (23MPH)

May improve operation

above 20kn (23MPH)

one

shim

taper down

more angle

Copyright © 2009 Airmar Technology Corp.

Figure 6. Screw locations on bracket

screw (4)

stabilizing

screw

Copyright © 2009 Airmar Technology Corp.

hole (2)

mate with

bosses

NOTE: Draw an “X”

at 21mm (1/2") from

the top and bottom

of both slots.

taper up

two shims

taper up

on shim