2. Improper installation of the transducer can alter the efficiency and accuracy of the entire

system.

3. If your boat or transducer is out of the water for a period of time, it may take a short

period of time for the transducer to become thoroughly "wetted" when returned to the

water. Also, re-entry may cause the turbulence which will create air bubbles on the "eye"

of the transducer. The bubbles will disappear in a short time or can be removed by

rubbing the transducer "eye" with your fingers while the transducer is in the water.

4. If your instrument should fail to function, be sure to check all the electrical connections

before removing the transducer or calling a serviceman.

5. Inspect your transducer cable and make sure that it has not been cut or damaged to the

point where it will affect the performance of the transducer. A slight nick or cut, exposing

the outer cable, can be repaired by wrapping with electrical tape. A transducer can be

damaged if the inner cable and outer cable are allowed to make contact. Such a problem

can sometimes be corrected by properly splicing the coaxial cable. This should only be

attemped by a qualified service technician.

6. If your unit is not working properly and you suspect the problem might be in your

transducer, we would recommend you borrow a unit from a friend and try it on your boat.

If the symptoms are the same, you can almost be assured that the problem is in the

transducer.

TRANSOM MOUNTING PROCEDURE

Step 1

MOUNTING LOCATION - It is important that the transducer be mounted on the transom where

water flow is in constant contact with the transducer. You may wish to observe the rear of the

boat while it is moving through the water to determine the best mounting location.

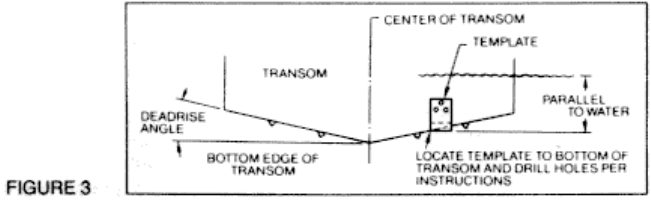

Step 2 (Aluminum Boats)

BRACKET INSTALLATION To install the metal bracket on an aluminum boat locate the template

on the transom between rows of rivets, or ribs that are on the bottom of the boat. NOTE:

Template is on the last page of the manual. Align the template so that the bottom corner of the

template nearest the center of the transom is on the bottom edge of the transom. (See figure 3.)

Once the location is determined mark and drill three 7/64" dia holes noted on the template. Attach

the metal bracket using three #10 self threading screws supplied. Be sure to align holes in the

center of the bracket slots. On some aluminum boats it may be necessary to use a wood back-up

plate. It is important to use a silicone sealant between the screwhead and bracket in order to

prevent leaking. (See Figure 4).