AIR

AND LUBE REQUIREMENTS

PAGE 3 OF 8

66602X-X

MODEL

DESCRIPTION CHART

WARNING EXCESSIVE AIR PRESSURE. Can cause pump

damage, personal injury or property damage.

S A filter capable of filtering out particles larger than 50 microns

should be used on the air supply. In most applications there is no

lubrication required other than the "O"ring lubricant which is apĆ

plied during assembly or repair.

S The pump can be rotated 360_to suit the application. It may be

mounted upside down or on the wall with no effect on suction lift or

operating efficiency. The filter and regulator need to be oriented in

a normal vertical direction to function properly.

S Pipe plugs included for the material inlets, they can be switched to

accommodate piping requirements however the fluid inlet must alĆ

ways be in the port closest to the mounting base.

S When lubricated air is necessary, supply the air lubricator with a

good grade of SAE 90 wt. non-detergent oil and set the lubricator

to a rate not to exceed one drop per minute.

INSTALLATION

S NOTICE: Re-torque fasteners prior to use. Refer to page step

#22 on page 7 for information.

S Apply tape or pipe sealant to threads upon assembly to preĆ

vent leakage.

S Secure the diaphragm pump legs to a suitable surface to insure

against damage by vibration.

S To avoid problems install a particle fluid filter to screen out foreign

matter 1/32'' or larger in diameter.

S The pump is not recommended for submerged applications.

S When the diaphragm pump is used in a forced-feed (flooded inlet)

situation it is recommended that a ``CheckValve'' be installedat the

air inlet.

OPERATING INSTRUCTIONS

S Always flush the pump with a solvent compatible with the material

being pumped if the material being pumped is subject to ``setting

up" when not in use for a period of time.

S Disconnect the air supply from the pump if it is to be inactive for a

few hours.

FLUID

S The outlet material volume is governed not only by the air supply

but also by the material supply available at the inlet. The materialĆ

supply tubing should not be too small or restrictive. Be sure not to

use hose which might collapse.

MAINTENANCE

Refer to the part list pg. 4 for Service Kit Information, parts view on

pg. 5. and Repair Proceedures on pgs 6 and 7.

S Certain ARO ``Smart Parts" are indicated which should be availĆ

able for fast repair and reduction of down time.

S Provide a clean work surface to protect sensitive internal moving

parts from contamination from dirt and foreign matter during serĆ

vice disassembly and reassembly.

S Keep good records of service activity and include pump in prevenĆ

tive maintenance program.

SER

VICE KITS

66602X- CHECK VALVE

DIAPHRAGM &

AIR SECTION REBUILD KIT

-344 637274-34 637275-44 637273-344

-34D 637274-3D 637275-4D 637273-34D

-34E 637274-3E 637275-4E 637273-34E

-644 637274-64 637275-44 637273-644

-64D 637274-6D 637275-4D 637273-64D

-64E 637274-6E 637275-4E 637273-64E

S VitonR andHytrelRare registered trademarksofthe DuPontCompany S KynarR isa registeredtrademark ofPenwalt Corp S FluorazR isa registered trademark of Greene,Tweed& Co.Inc.

S SantopreneRisaregisteredtrademarkofMonsanto Company,licensedtoAdvancedElastomer Systems,L.P. S Key-LubeRisaregistered trademarkof KeyIndustries

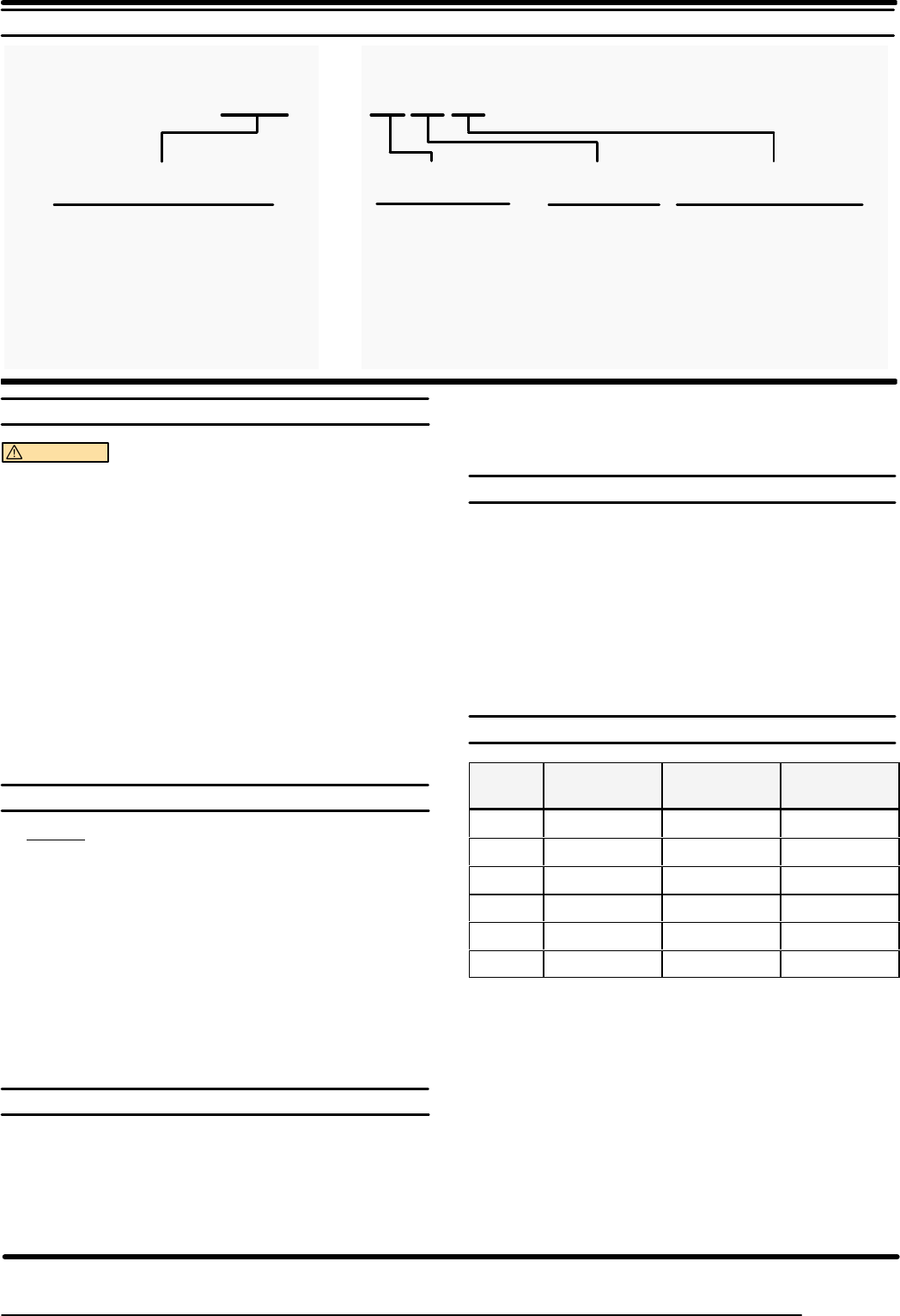

6660 X X

BODY MATERIAL,

INLET/OUTLET OPTION

CHECK

MATERIAL

DIAPHRAGM/O–RING

MATERIAL

43 POLYPROPYLENE

6 ACETAL

23 POLYPROPYLENE,(1)INLET/(1)OUTLET

26 GROUNDABLE ACETAL, (1)INLET/(1)OUTLET

2J POLYPROPYLENE,(1)INLET/(2)OUTLET

2H GROUNDABLE ACETAL, (1)INLET/(2)OUTLET

2L POLYPROPYLENE,(2)INLET/(1)OUTLET

2M GROUNDABLE ACETAL, (2)INLET/(1)OUTLET

2N POLYPROPYLENE,(2)INLET/(2)OUTLET

2P GROUNDABLE ACETAL,(2)INLET/(2)OUTLET

CHECK VALVE SEAT

MATERIAL

4

.F.E

D R

E SANTOPRENER/FLUORAZ

– X X X

FLUID SECTION MATERIAL OPTIONS

BASIC MODEL NO.

PTFE

PTFE/T

PTFE/FLOURAZ

PTFE