18

Main circuit terminal specifications

(2) Earthing (Grounding) precautions

Always earth (ground) the motor and inverter.

1)Purpose of earthing (grounding)

Generally, an electrical apparatus has an earth (ground) terminal, which must be connected to the ground before use.

An electrical circuit is usually insulated by an insulating material and encased. However, it is impossible to manufacture

an insulating material that can shut off a leakage current completely, and actually, a slight current flow into the case.

The purpose of earthing (grounding) the case of an electrical apparatus is to prevent operator from getting an electric

shock from this leakage current when touching it.

To avoid the influence of external noises, this earthing (grounding) is important to audio equipment, sensors, computers

and other apparatuses that handle low-level signals or operate very fast.

2)Earthing (grounding) methods and earthing (grounding) work

As described previously, earthing (grounding) is roughly classified into an electrical shock prevention type and a noise-

affected malfunction prevention type. Therefore, these two types should be discriminated clearly, and the following

work must be done to prevent the leakage current having the inverter's high frequency components from entering the

malfunction prevention type earthing (grounding):

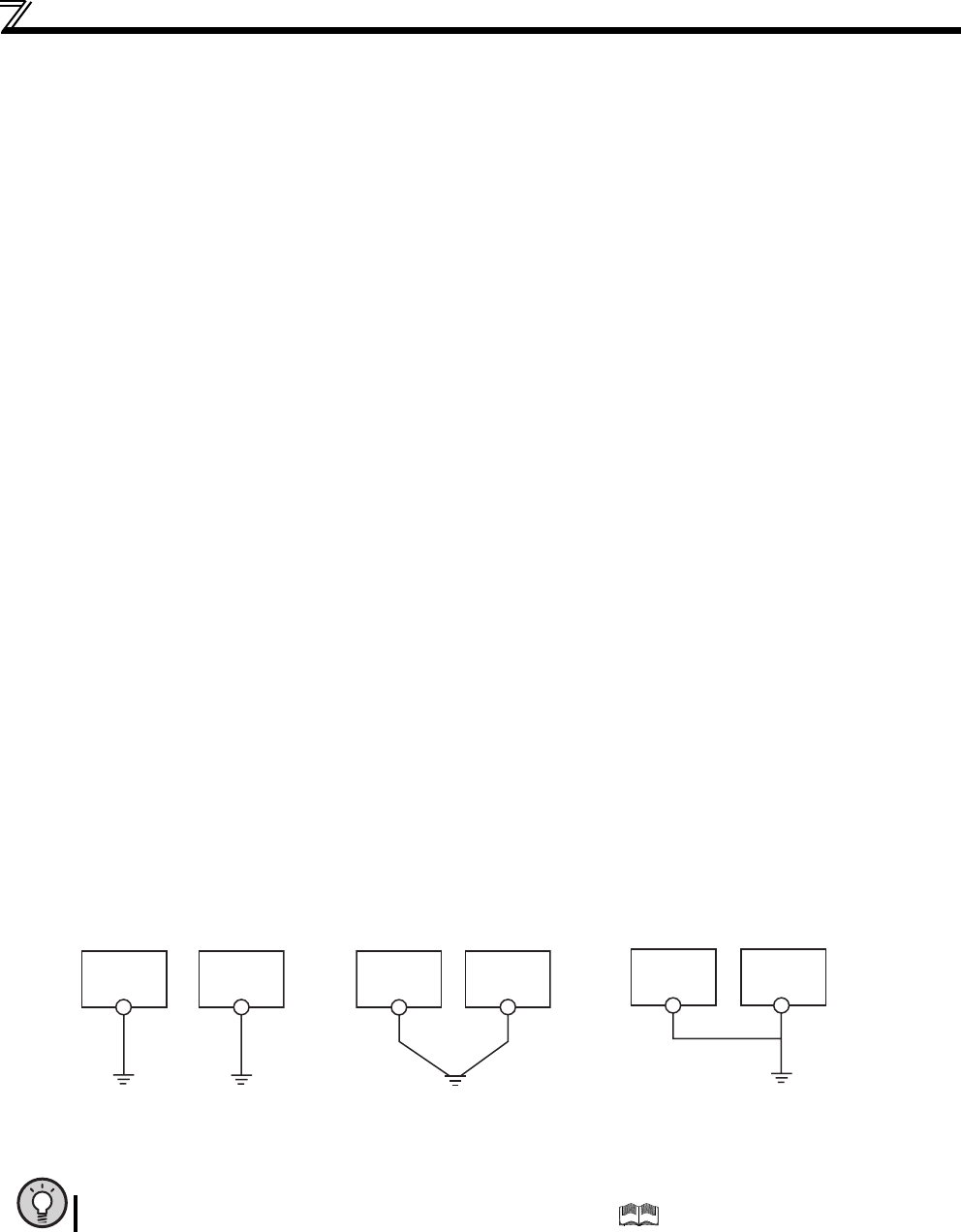

(a)Where possible, use independent earthing (grounding) for the inverter. If independent earthing (grounding) (I) is

impossible, use joint earthing (grounding) (II) where the inverter is connected with the other equipment at an

earthing (grounding) point. Joint earthing (grounding) as in (III) must be avoided as the inverter is connected with the

other equipment by a common earth (ground) cable.

Also a leakage current including many high frequency components flows in the earth (ground) cables of the inverter

and inverter-driven motor. Therefore, they must use the independent earthing (grounding) method and be separated

from the earthing (grounding) of equipment sensitive to the aforementioned noises.

In a tall building, it will be a good policy to use the noise malfunction prevention type earthing (grounding) with steel

frames and carry out electric shock prevention type earthing (grounding) in the independent earthing (grounding)

method.

(b)This inverter must be earthed (grounded). Earthing (Grounding) must conform to the requirements of national and

local safety regulations and electrical codes. (NEC section 250, IEC 536 class 1 and other applicable standards).

Use an neutral-point earthed (grounded) power supply for 400V class inverter in compliance with EN standard.

(c)Use the thickest possible earth (ground) cable. The earth (ground) cable should be of not less than the size indicated

in the table on the previous page 17.

(d)The earthing (grounding) point should be as near as possible to the inverter, and the earth (ground) cable length

should be as short as possible.

(e)Run the earth (ground) cable as far away as possible from the I/O wiring of equipment sensitive to noises and run

them in parallel in the minimum distance.

POINT

To be compliant with the European Directive (Low Voltage Directive), refer to the Installation Guideline.

Inverter

Other

equipment

(I)Independent earthing.......Best

Inverter

Other

equipment

(II)Common earthing.......Good

Inverter

Other

equipment

(III)Common earthing.......Not allowed