7URXEOHVKRRWLQJ

7URXEOHVKRRWLQJ7URXEOHVKRRWLQJ

7URXEOHVKRRWLQJ

9)FRQWURO

9)FRQWURO9)FRQWURO

9)FRQWURO

Y

Y

N

N

Y

N

Y

N

Y

N

Y

Y

Y

N

Y

N

N

Y

Y

N

N

N

N

N

N

Y

Y

Y

Y

N

Y

Y

N

N

N

N

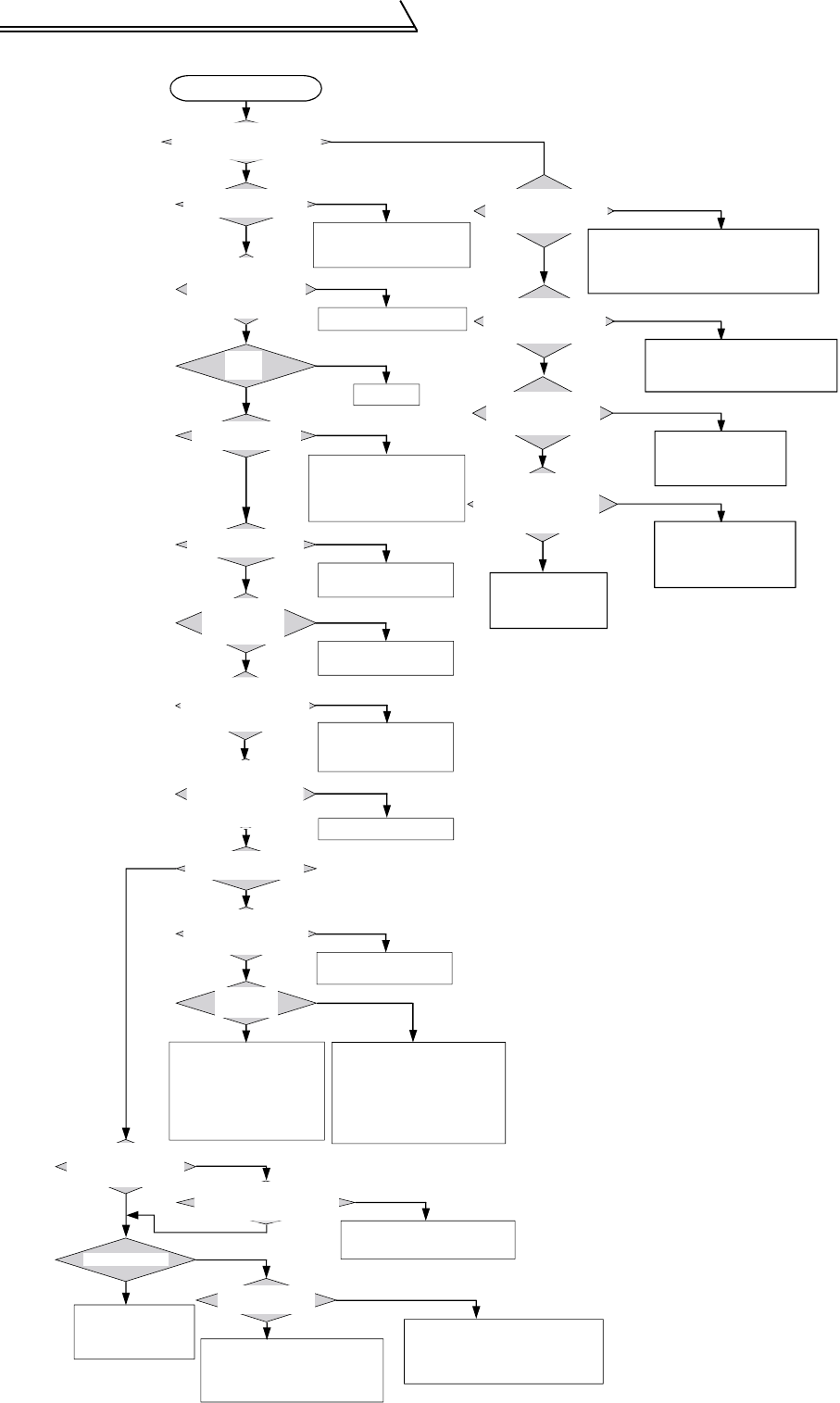

The motor does not rotate.

Is there no alarm output

to the operation panel?

Is the secondary side

wiring (U, V, W) of the

inverter correct without

open cables?

Is the start command

input?

Are the MRS and RES

signals both off?

Is the speed command

input?

Is an analog

input used?

Apply a voltage to the analog

input terminals (across 2-5).

Also, to calibrate the No. 2

terminal, adjust the bias and

gain of the analog voltage

using Pr. 902 and Pr. 903.

Is the torque boost

setting low?

Set reverse rotation

prevention (Pr. 78)

correctly.

Open the brake.

Set the speed from

the PU.

Turn on the multiple speed

(*RH, RM, RL, REX).

*The terminal functions vary

with input terminal

assignment (Pr. 180 to Pr. 183,

Pr. 187).

Wire the cables correctly.

Make communication setting.

Increase the torque boost.

(Do not increase it too high.

Doing so may cause the motor to

overheat. Increase it to about 10%.)

Are the operation panel

LED off and the charge

lamp on?

Are the operation panel

LED on and the charge

lamp off?

Are the earth leakage

breaker and magnetic

contactor on?

Turn on the earth

leakage breaker

and magnetic contactor.

Check for a low voltage,

phase failure, poor

connection or the like

and take corrective action.

Is the load light?

Is operation performed

without using

communication?

Are the charge lamp

on and the operation

panel LED indication given?

Is the maximum

setting (Pr. 1)

other than 0?

Perform wiring correctly.

PU: Press FWD (REV).

External: Turn on STF (STR).

Also check that both

STF and STR are not on.

Turn off the MRS and

RES signals.

Make the maximum

setting correctly.

Check the alarm definition,

remove the cause of the

alarm, and reset the inverter.

Is reverse rotation

prevention (Pr. 78)

set to enable rotation

in the rotation direction?

When the

electromagnetic brake

is used, is the

electromagnetic

brake open?

Is an external command

used for the speed

command?

Is any cable open?

Are the station number and

so on set correctly?

Lighten the load or increase

the motor and inverter capacities.

The load is excessive,

resulting in a motor lock status.

N

Y

Control

Pr.800

Set Pr.800.

2) Connect or DC reactor.

Please contact your

sales representative.

Please contact your

sales representative.

Are the voltages of the

main circuit power

supply voltage terminals

(R, S, T) normal?

1) Contact fault of the operation panel

2) Control power is not supplied.

(Check whether jumpers are connected

across R-R1 and S-S1.)

1) The jumper across P-P1 or

DC reactor is disconnected.