Series 830/840/860 Instruction Manual Chapter 2 Installation

IM-83/84/86-H 2-5

Wiring the Transducer

Side-Trak and Auto-Trak transducers require a +15, 0, –15 VDC power

supply and a readout device. Additionally, controllers require a set

point input (0-5 VDC standard, 4-20 mA optional). Transducers are

connected to the power supply, output signal and set point control

through either a

20-pin card-edge connector or 15-pin D-connector. Motor-operated ro-

tary valves use a 10-pin circular connector. Wiring instructions are

given for each type of connector on the following pages. If you are re-

placing another manufacturer’s transducer with a Sierra product, see the

factory-supplied wiring supplement for instructions specific to your in-

stallation.

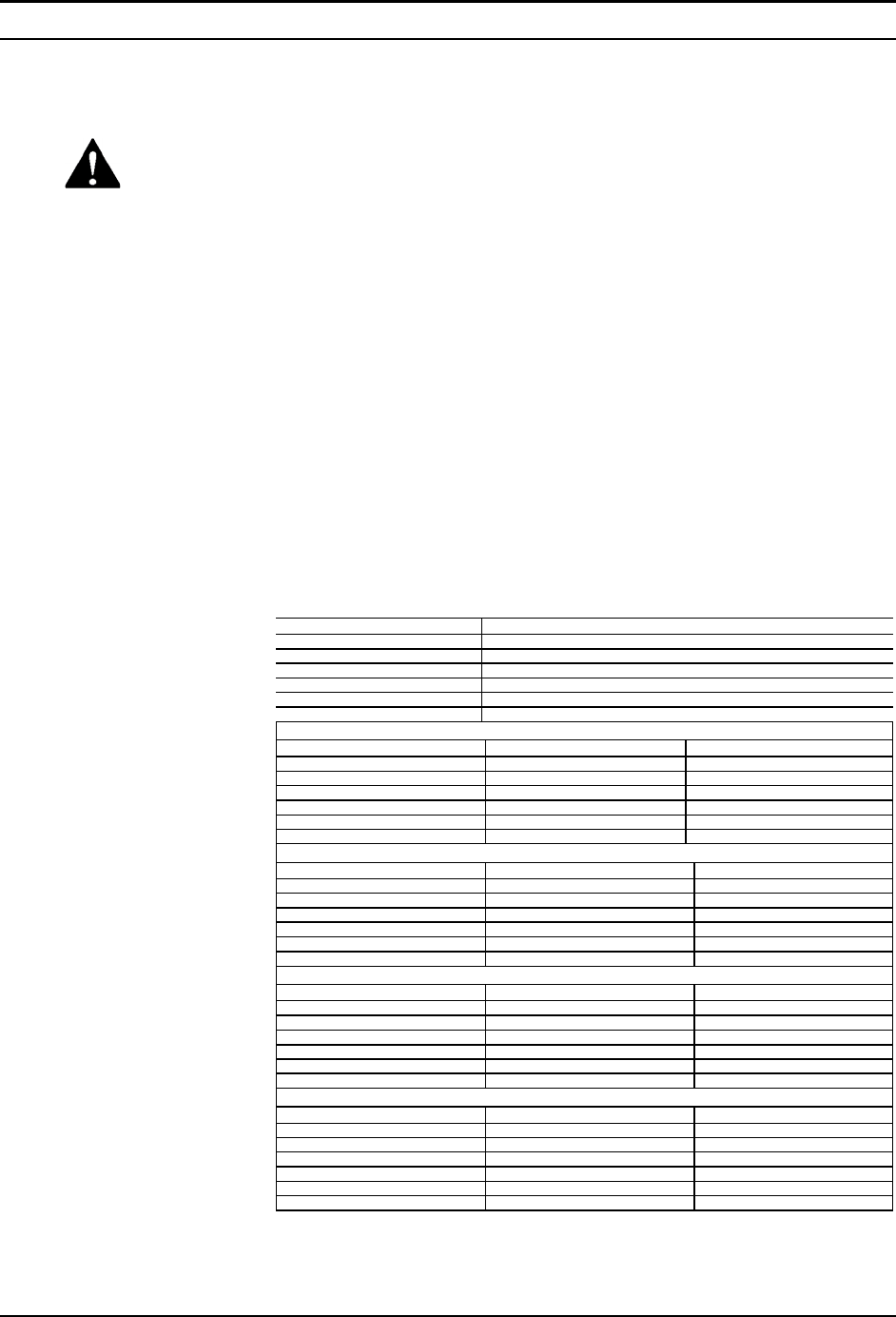

Recommended Wire Gauges

Using the correct wire gauge for cabling runs to transducers en-

hances system reliability. For cable runs over 150 feet (46 m), con-

sider using a local power supply.

Model 830/860M (all ranges)

Distance in feet

Recommended Min. Wire Gauge

25

34

50

32

100

28

200

26

300

24

500

22

Model 840/860C Low Flow, 15 Volt Valve

Distance in feet

COM & –15 VDC Pins

All Others

25

30

34

50

28

32

75

26

28

100

26

28

125

24

26

150

24

26

Model 840/860C Low & Medium Flow, 30 Volt Valve

Distance in feet

COM & –15 VDC Pins

All Others

25

26

34

50

24

32

75

22

28

100

22

26

125

20

26

150

20

26

Model 840/860C High Flow, 30 Volt Valve

Distance in feet

+15 & –15 VDC Pins

All Others

25

22

34

50

20

32

75

18

28

100

16

26

125

16

26

150

14

26

Model 840/860C Motor-Operated Rotary Valve

Distance in feet

+15, –15 & COM Pins

All Others

25

26

34

50

24

32

75

22

28

100

22

26

125

20

26

150

20

26

Warning!

Follow National Electric

Code or your local code

safety practices when wir-

ing or connecting this unit

to a power source. Only

qualified personnel should

wire the transducer.