307985 13

Service

Disconnecting the Displacement Pump

NOTE: For displacement pump repair instructions,

refer to the separate displacement pump manual

307983, supplied.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

1. Flush the pump if possible. Stop the pump at the

bottom of its stroke. Relieve the pressure.

2. Disconnect all hoses and remove the pump from

its mounting.

3. Unscrew the coupling nut (14) from the displace-

ment rod (R). Remove the coupling collars (15).

See Fig. 4.

4. Unscrew the lower locknut (9) and lockwasher (7)

from the return mounting tube (11).

5. Unscrew the swivel union (S) from the supply

mounting tube (12).

CAUTION

If you are removing the mounting tubes, wrench the

tubes close to the motor base to prevent thread

damage in the base. Use thread sealant on the male

threads when reinstalling.

Reconnecting the Displacement Pump

1. Position the displacement pump on the mounting

tubes (11, 12). Thread the upper locknut (9) onto

the return mounting tube (11) a couple of turns.

Tighten the swivel union (S) securely onto the

supply mounting tube (12). See Fig. 4.

2. Butt the connecting rod (4) and displacement rod

(R) together; if necessary, adjust the locknuts (9)

on the return mounting tube (11) to align the rods.

3. Position the coupling collars (15) so they engage

with the connecting rod (4) and displacement rod

(R). Lower the coupling nut (14) over the coupling

collars and screw it securely onto the displacement

rod.

4. Tighten the locknuts (9) securely.

5. Remount the pump and connect all hoses.

6. Turn on the air to the motor and run the pump

slowly. Adjust the locknuts (9) on the return mount-

ing tube (11) as necessary until the pump operates

smoothly at minimum air pressure to the motor.

Tighten the locknuts securely.

7. Reconnect the ground wire if it was disconnected

during repair.

8. If the pump is not immersed, fill the packing nut/

wet-cup 1/2 full of compatible solvent.

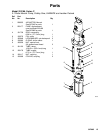

Fig. 4

1

2

Torque to 65–75 ft-lb (88–102 N.m).

Lubricate.

06086

1

3

4

6

7

9

11

12

14

15

7

8

9

S

R

3

Use thread sealant when reinstalling.

3

2

2

Model 223186

Shown

1