Reciprocator Repair

312350K 17

9. Use a spanner wrench to screw piston (22) onto

displacement rod (34). Torque to 40 to 48 ft-lb (54 to

65 N.m).

10. Lay Assemblies A and B (F

IG. 24) on work bench.

11. Slide Assembly B in into center of tool (D), Part No.

189305. Align upper detent holes (C) of yoke (9)

with center line of tool (D) (F

IG. 24).

12. Insert spring (6) and one ball (7) into valve stop (26)

of Assembly A. Tilt valve stop and start guiding it

into tool (D), making sure ball is sliding into rounded

slot in tool (D). Place other ball at the other end of

spring and push it in with your thumb while rotating

valve stop (26) until spring is horizontal and balls

are in place. Continue holding this assembly

together (F

IG. 24).

13. Slide valve stop assembly down into tool. Make sure

balls (7) snap into upper set of holes (C) in yoke (9)

and curved ends of guide clamp have engaged

valve sleeve (29) groove. Slide tool (D) back over

rod (12) to remove it (F

IG. 24).

14. Place adapter (43) in a vise. Install seals as

described in Replacing Throat Seal Reassembly

instructions, page 12.

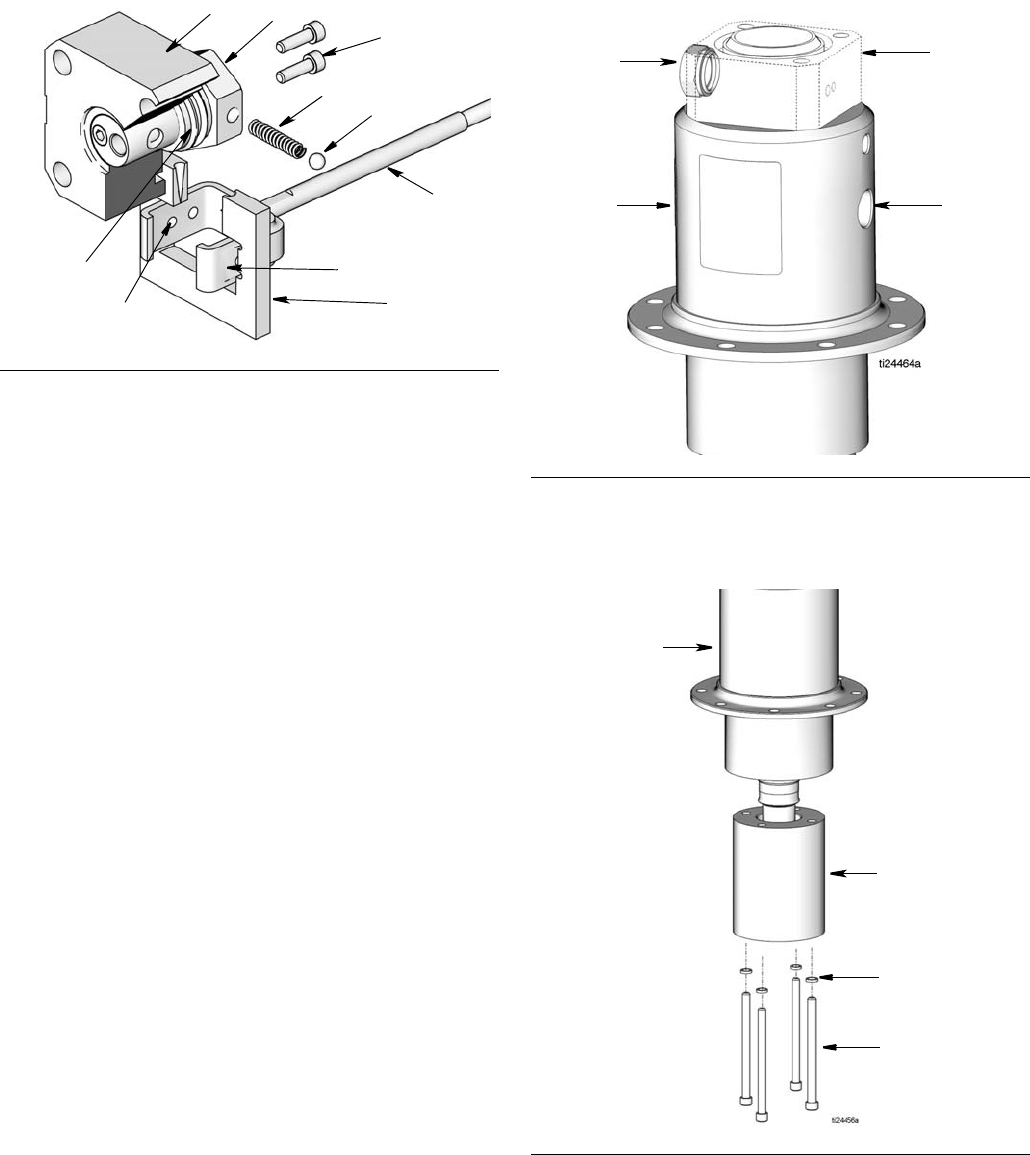

15. Reassemble cylinder cap (32) to motor housing

(43). Install lock washers (52) and cap screws (46)

(F

IG. 13). Torque the capscrews to 28-32 ft-lb (38 to

43 N.m).

NOTE: When attaching the motor housing (43) onto the

bottom cylinder cap (32), be sure that the port (43b) in

the motor housing and the port (32b) in the bottom cylin-

der cap are facing opposite directions as shown in F

IG.

25.

16. Attach adapter (8) to motor housing (43) using four

capscrews (15) and lock washers (27). Torque

capscrews to 170-180 in.-lbs (19-20 N.m).

FIG. 24

9

ti10606a

12

D

C

7

6

Assembly A

Assembly B

31

26

51

29

FIG. 25

FIG. 26

32b

32

43b

43

8

43

27

15