5 4321P24

H

OOILFMCM

2

12 11

AT

24VDC

6

H

L

Reverse

Forward

Common for

in

p

ut si

g

nals

Frequency mete

r

(0..10V, 1mA)

Motor thermisto

r

(PTC)

Set valu

e

(4...20mA)

A 01

= 01 (Frequency set value on input O or OI)

A 02

= 01 (Start signal on FW/RV)

F 02

= 10 (acceleration time 10 sec.)

F 03

= 10 (deceleration time 10 sec.)

C 01

= 00 (FW: Start forward run via input 1)

C 02

= 01 (RV: Start reverse run via input 2)

C 03

= 16 (AT: Use current input 4-20mA for set value)

C 05

= 19 (PTC on input 5)

The inverter can now be started via input 1 (forward run) or input 2 (reverse run). If the

inputs RV and FW are both closed, the inverter is stopped. If input AT is configured as

normall

y

o

p

en contact and is closed

,

current in

p

ut on

O

I is used for set

v

alue

.

Wirin

g

exam

p

le: Set value 4..20mA and thermistor

65

4321P24

HOOILFMCM21211

AT

24VDC

CF1

CF2

+24V

RUN

FA1

L

Reverse

Forward

Common for

in

p

ut si

g

nals

Frequency meter

(

0..10V

,

1mA

)

Wiring example: Fixed set values; FA1 output and RUN output

Parameters for functions

A 01

,

A 02

,

F 02

,

F 03

,

C 01

,

C 02

, and

C 03

are set exactly the

same as in the example above. Additionally,

C 04

is set to 02 (CF1) and

C 05

is set to 03

(CF2). Fixed frequency set values are set via functions

A 21

,

A 22

, and

A 23

using parame-

ters 0 to 360 (= frequency 0 to 360Hz). The inverter can now be started via input 1 (FW) or

input 2 (RV). If the inputs RV and FW are both closed, the inverter is stopped. If none of the

di

g

ital in

p

uts CF1 or CF2 is closed, fre

q

uenc

y

set value can be set usin

g

analo

g

in

p

uts O/OI.

P

A 72

0-300 l/h

= 0-100%)

I

A 73

D

A 74

+

+

+

F 01

+

Display

d 04

A 76 =

01

[PID current value at

terminals (O-L)]

0 – 10V = 0 – 500 l/h

A 01

= 01 (fixed set values)

A 21

= 100 l/h (=33%)

A 22

= 200 l/h (=66%)

A 23

= 300 l/h (=100%)

A 75

= 3.00

A 75

= 3.00

Frequency set value

0-100% =50Hz; limited to 10Hz min.

0-6V-10V

Set value is given in fixed intervals: 100, 200, 300l/h. The current value is input by a sensor (0-

500l/h = 0-10V). When the difference is greater than 20% a warning is output. The frequency

must not fall below 10 Hz. The set value and current value are displayed as flow rate in l/h

(300l/h = 100% = 50Hz maximum frequency).

In order to display the correct value,

A 75

is set to 3.00 so that a set value of 100% corres-

ponds to a flow rate of 300l/h. In order to match the current value input (0-500l/h) to the set

value input (0-300l/h) the current value must be adjusted with parameters

A 11

to

A 14

, i.e.

A 14

must be set to 60% so that 300l/h process value corresponds to 100% current value.

Application example: Flow control

A flow control circuit is to be realized using the SJ100 inverter built in PID control.

0-300 l/h

= 0-6V

= 0-100%)

+

Flow rate

set value

Q

set

-

M

Flow rate current value Q

cur

f

cur

A 14 = 60%

set value adjustment

-

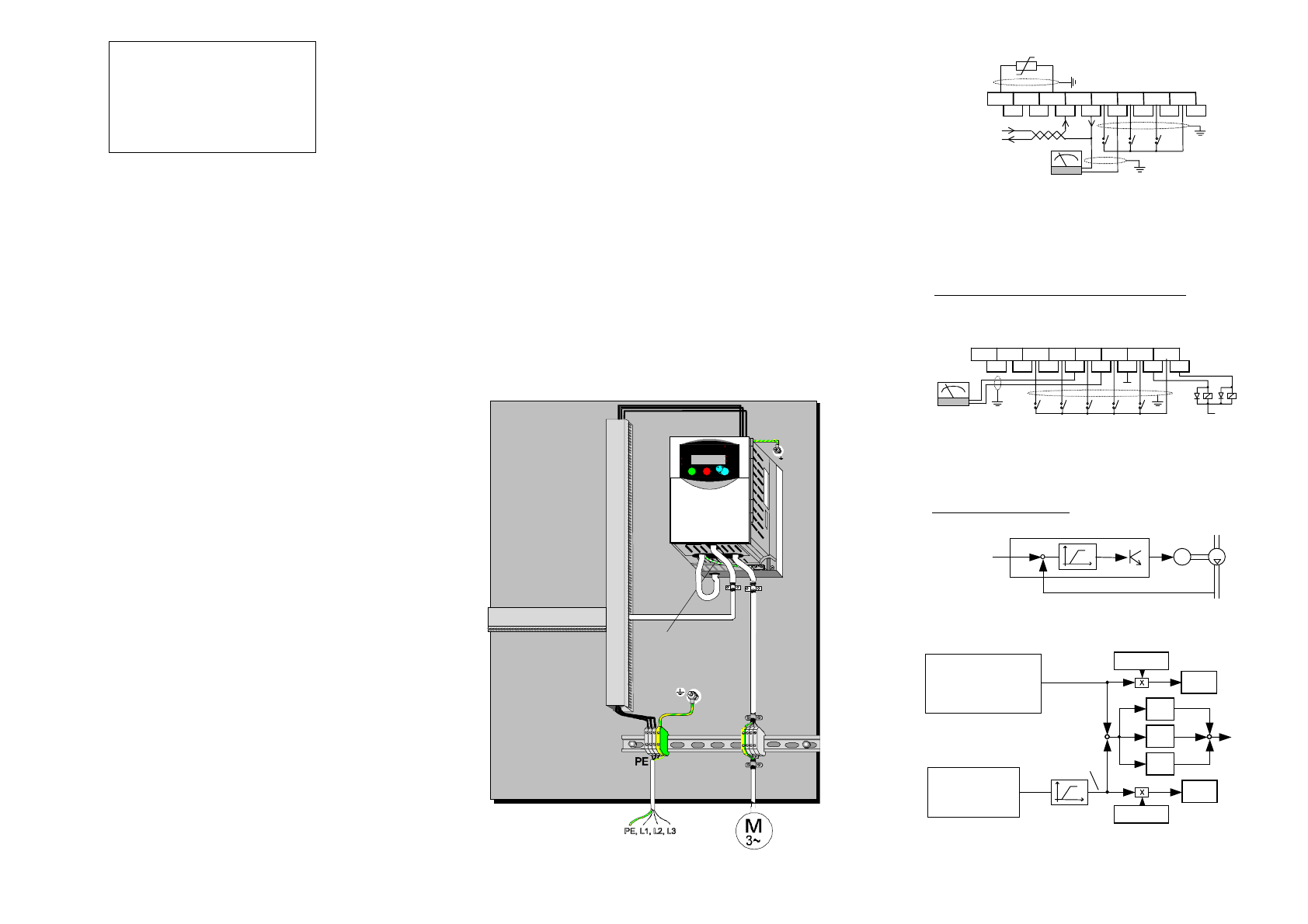

HITACHI INVERTER

SJ100 SERIES

QUICK REFERENCE GUIDE (Part 2/2)

Single phase input 200V class

Three phase input 200V class

Three phase input 400V class

CE-EMC Installation

This instruction describes the electromagnetically compatible setup o

f

your drive system.

1. As an enduser you must ensure that the HF impedance between

frequency inverter, filter and ground is as small as possible.

•

See to it that the connections are metallic and have the largest

possible areas (zink-plated mounting plates)

2. Conductor loops act like antennas, especially when they encompass

large areas. Consequently:

•

Avoid unnecessary conductor loops

•

Avoid parallel arrangement of „clean“ and interference-prone

conductors

3. Lay the motor cable and all analog and digital contol lines shielded.

•

You should allow the effective shield area of these lines to remain as

large as possible; i.e., do not move the shield further away than

absolutely necessary.

•

With compact systems, if for example the frequency inverter is

communicating with the steering unit, in the same control cabinet

connected at the same PE-potential, the screen of control lines should

be put on, on both sides with PE. With branch systems, if for example

the communicating steering unit is not in the same control cabinet and

there is a distance between the systems, we recommend to put on the

screen of control lines only on the side of the frequency inverter. If it is

possible, direct in the cable entry section of the steering unit. The

screen of Motor cabels always must be put on, on both sides with PE.

•

The large area contact between shield and PE-potential you can

realise with a metal PG screw connection or a metallic mounting clip.

•

Use only copper mesh cable (CY) with 85% coverage

•

The shielding should not be interrupted at any point in the cable. If

the use of reactors, contactors, terminals or safety switches in the motor

output is necessary, the unshielded section should be kept as small as

possible.

•

Some motors have a rubber gasket between terminal box and motor

housing. Very often, the terminal boxes, and particularly the threads for

the metal PG screw connections, are painted. Make sure there is always

a good metallic connection between the shielding of the motor cable,

the metal PG screw connection, the terminal box and the motor

housing, and carefully remove this paint if necessary.

4. Very frequently, interference is coupled in through installation

cables. This influence you can minimize:

•

Lay interfering cables separately, a minimum of 0.25 m from cables

susceptible to interference.A particularly critical point is laying cables

parallel over larger distances. If two cables intersect, the interference is

smallest if they intersect at an angle of 90°. Cables susceptible to

interference should therefore only intersect motor cables, intermediate

circuit cables, or the wiring of a rheostat at right angles and never be

laid parallel to them over larger distances.

5. The distance between an interference source and an interference

sink (interference-threatened device) essentially determines the

effects of the emitted interference on the interference sink.

•

You should use only interference-free devices and maintain a

minimum distance of 0.25 m from the drive.

6. Safety measures

•

Ensure that the protective conductor terminal (PE) of the filter is

properly connected with the protective conductor terminal of the

frequency inverter. An HF ground connection via metal contact

between the housings of the filter and the frequency inverter, or solely

via cable shield, is not permitted as protective conductor connection.

The filter must be solidly and permanently connected with the ground

potential so as to preclude the danger of electric shock upon touching

the filter if a fault occurs. You can achieve this by:

- connecting it with a grounding conductor of at least 10 mm

2

;

- connecting a second grounding conductor, connected with a

separate grounding terminal, parallel to the protective conductor

(The cross section of each single protective conductor terminal

must be designed for the required nominal load)

HITACHI

55.0

RUN

STOP

RESET

MI MAX

RUN

PRG

Hz

A

POWER

2

STR

FUNC.

1

SJ1 00

WARNING

HAZARD OF PERSONAL INJURY OR

ELECTRIC SHOCK

Disconnect incoming power and wait

5 minutes before opening front case.

PE connection

Figure: Hitachi frequency inverter with footprint filter

9 10 11