Form P6401 Edition 6 3

than the Vent plug from the upper side of the motor and

connect an oil line from a gravity feed reservoir. Connect an

overflow line to the Level Plug opening and run it to a pump

to return the lubricant to the gravity feed reservoir.

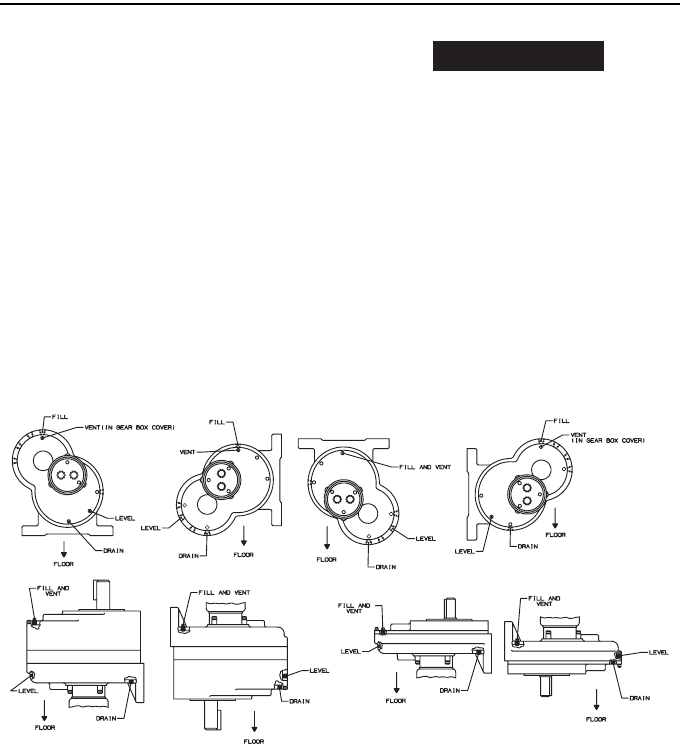

If the Motor is mounted in any position other than

that illustrated, contact an Ingersoll-Rand

Representative for oil level and venting recommendations.

Direction of Shaft Rotation

Series 92N Non–reversible Motors are assembled at the

factory so that the Motor Shaft (36) rotates counterclockwise

when facing the end of the Shaft. When desired, the direction

of the shaft rotation can be changed as follows:

1. Stand the Motor upright on a workbench with the Motor

Housing Cover (1) upward and secure it in position by

clamping the base with a C–clamp.

2. Remove the four Housing Cover Cap Screws (2).

3. Being careful not to damage the Cylinder Seals (8A), pull

the Motor Housing Cover and the Motor Housing (11) off

the Gear Box (18).

4. Grasp the Cylinder (8) with both hands and carefully work

the motor from the Gear Box.

5. While holding the Cylinder with one hand, drive against

the splined end of the Rotor (12) with a soft hammer until

the Front Rotor Bearing (13) comes free from the rotor

shaft.

6. Withdraw the Front Rotor Bearing, Front Rotor Bearing

Spacer Assembly (14) and Front End Plate (7).

7. Withdraw the Cylinder (8), turn it end–for–end, and slide

it back over the Rotor.

8. Install the Front End Plate, Front Rotor Bearing Spacer

Assembly and Front Rotor Bearing.

NOTICE

Press against the inner ring of the Bearing when

pressing the Front Rotor Bearing on the rotor shaft.

9. Align the dowel hole in both End Plates and Cylinder, and

insert the Cylinder Dowel (9) so that it protrudes from the

Rear End Plate.

10. Place the Housing Cover Gasket (4) in the recess in the

Housing Cover so that the dowel notch in the Gasket is

aligned with the dowel hole in the Cover.

11. Set the motor assembly in the Cover so that the Cylinder

Dowel enters the dowel hole.

12. Slide the Motor Housing (11) over the Cylinder and

against the Motor Housing Cover.

13. Place the Gear Box Gasket (17) on the face of the Front

End Plate.

14. Pick up the entire assembly and being careful not to

damage the Cylinder Seals, work it into the pilot recess in

the gear box.

15. Install the Housing Cover Cap Screws and, with the

Motor running at a slow speed using air pressure of 30 to

40 psig (2.07 to 2.76 bar/207 to 276 kPa), alternately

tighten the Screws to 28 to 31 ft–lb. (38.0 to 42.0 Nm)

torque.

(Dwg. TPB490)