37

Check first when you have a trouble

∗1 Resetting the inverter initializes the internal cumulative heat value of the electronic thermal relay function.

∗2 This protective function does not function in the initial status.

∗3 This protective function is available with the three-phase power input specification model only.

8.3 Check first when you have a trouble

* For further information on troubleshooting, refer to the Instruction Manual (Applied).

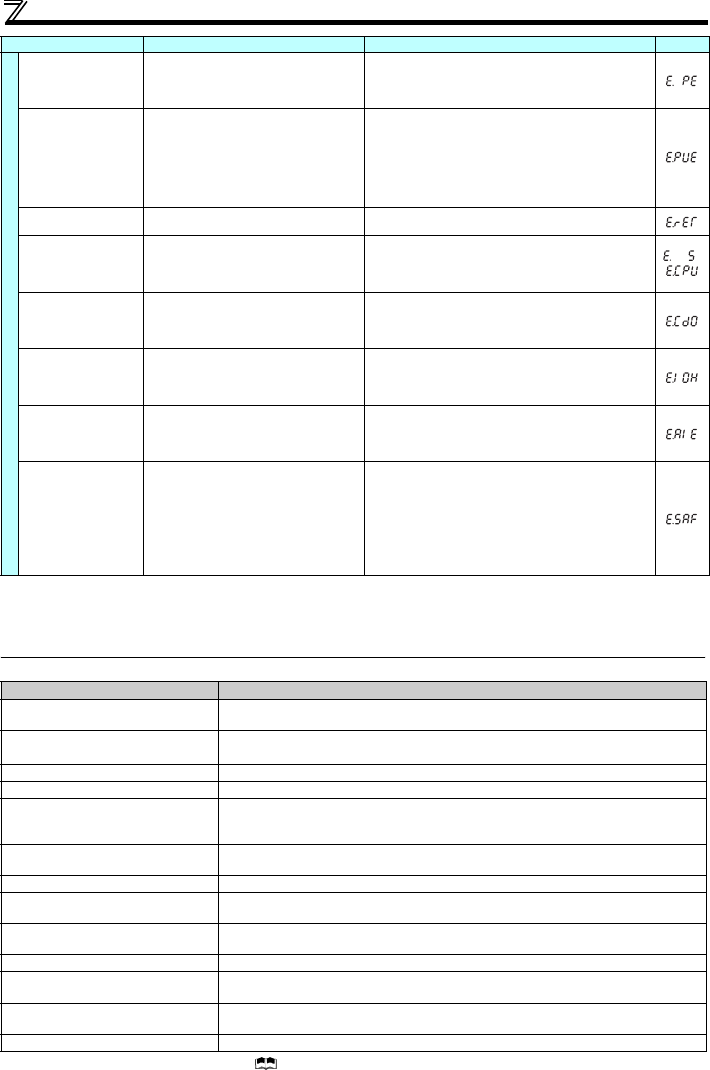

Fault

Parameter storage

device fault

Operation of the component where parameters

are stored (control circuit board) has become

abnormal.

Please contact your sales representative.

When performing parameter write frequently for communication

purposes, set "1" in Pr. 342 to enable RAM write. Note that

powering OFF returns the inverter to the status before RAM write.

PU disconnection

y A communication error has occurred between

the PU and the inverter.

y The communication interval has exceeded the

permissible time period during RS-485

communication via the PU connector.

y The number of communication errors has

exceeded the number of retries.

y Connect the parameter unit cable securely.

y Check the communication data and communication settings.

y Increase the Pr. 122 PU communication check time interval setting.

Or set "9999" (no communication check).

Retry count excess ∗2

Operation restart within the set number of retries

has failed.

Eliminate the cause of the error preceding this error indication.

CPU fault

An error has occurred in the CPU and in the

peripheral circuits.

y Take measures against noises if there are devices producing

excess electrical noises around the inverter.

y If the situation does not improve after taking the above

measure, please contact your sales representative.

/

Output current detection

value exceeded ∗2

Output current has exceeded the output current

detection level, which was set in a parameter.

Check the settings of Pr. 150 Output current detection level, Pr. 151

Output current detection signal delay time, Pr. 166 Output current

detection signal retention time, Pr. 167 Output current detection

operation selection.

Inrush current limit

circuit fault

The resistor of the inrush current limit circuit has

overheated.

Configure a circuit where frequent power ON/OFF is not

repeated.

If the situation does not improve after taking the above measure,

please contact your sales representative.

Analog input fault

A voltage (current) has been input to terminal 4

when the setting in Pr. 267 Terminal 4 input

selection and the setting of voltage/current input

switch are different.

Give a frequency command by a current input or set Pr.267

Terminal 4 input selection, and set the voltage/current input switch

to voltage input.

Safety circuit fault

While a safety circuit fault is occurring, the

terminals across S1 and PC, or across S2 and

PC are opened.

y When not using the safety stop function, short across terminals

S1 and SC and across S2 and SC with shorting wire.

y When using the safety stop function, check that wiring of

terminal S1, S2 and SC is correct and the safety stop input

signal source such as safety relay module is operating properly.

Refer to the Safety stop function instruction manual (BCN-A211508-

000) for causes and countermeasures.

(Please contact your sales representative for the manual.)

Description Countermeasure

Motor does not start.

Check start and frequency command sources and enter a start command (STF, etc.) and a

frequency command.

Motor or machine is making abnormal

acoustic noise.

Take EMC measures if a steady operation cannot be performed due to EMI. Alternatively, set

the Pr.74 Input filter time constant setting higher.

Inverter generates abnormal noise. Install the fan cover correctly.

Motor generates heat abnormally. Clean the motor fan. Improve the environment.

Motor rotates in the opposite direction.

Connect phase sequence of the output cables (terminal U, V, W) to the motor correctly.

Alternatively, check the connection of the start signal. (STF: forward rotation, STR: reverse

rotation)

Speed greatly differs from the setting.

Check the settings of Pr.1 Maximum frequency, Pr.2 Minimum frequency, Pr.18 High speed maximum

frequency, and calibration parameters C2 to C7.

Acceleration/deceleration is not smooth. Reduce the load. Alternatively, increase the acceleration/deceleration time.

Speed varies during operation.

Check the frequency setting signals. If the load fluctuates, select General-purpose magnetic

flux vector control.

Operation mode is not changed properly.

Turn OFF the start signal (STF or STR). Check if Pr.79 Operation mode selection is set

appropriately.

Operation panel display is not operating. Check the wiring and the installation.

Motor current is large.

Increase/decrease the Pr.0 Torque boost setting value by 0.5% increments so that stall

prevention does not occur. Set the rated motor frequency to Pr.3 Base frequency.

Speed does not accelerate.

Check the settings of Pr.1 Maximum frequency, Pr.2 Minimum frequency, and calibration parameters

C2 to C7. To operate at 120Hz or higher, set Pr.18 High speed maximum frequency.

Unable to write parameter setting. Check Pr.77 Parameter write selection setting.

Function Name Description Corrective action Display