PAGE 22 — LT12 SERIES LIGHT TOWER • OPERATION MANUAL — REV. #12 (01/20/09)

INSPECTION

BEFORE STARTING

Read all safety instructions at the beginning of 1.

manual.

Clean the light tower, removing dirt and dust, particularly 2.

the engine cooling air inlet and air cleaner.

Check the air fi lter for dirt and dust. If air fi lter is dirty, 3.

replace air fi lter with a new one as required.

Check all fastening nuts and bolts for tightness.4.

INDOOR INSTALLATION

Exhaust gases from diesel engines are extremely

poisonous. Whenever an engine is installed indoors the

exhaust fumes must be vented to the outside. The engine

should be installed at least two feet from any outside wall.

Using an exhaust pipe which is too long or too small can

cause excessive back pressure which will cause the engine

to heat excessively and possibly burn the valves.

Eliminate the danger of deadly carbon monoxide gas.

Remember that exhaust fumes from any gasoline or

diesel engine are very poisonous if discharged in a closed

area. If the light tower is installed indoors, you must make

provisions for venting the engine exhaust to the outside of

the building.

ENGINE OIL CHECK

To check the engine oil level, make sure the light tower is

placed on secure level ground with the engine stopped.

Remove the fi ller cap/dipstick from its holder and wipe 1.

it clean.

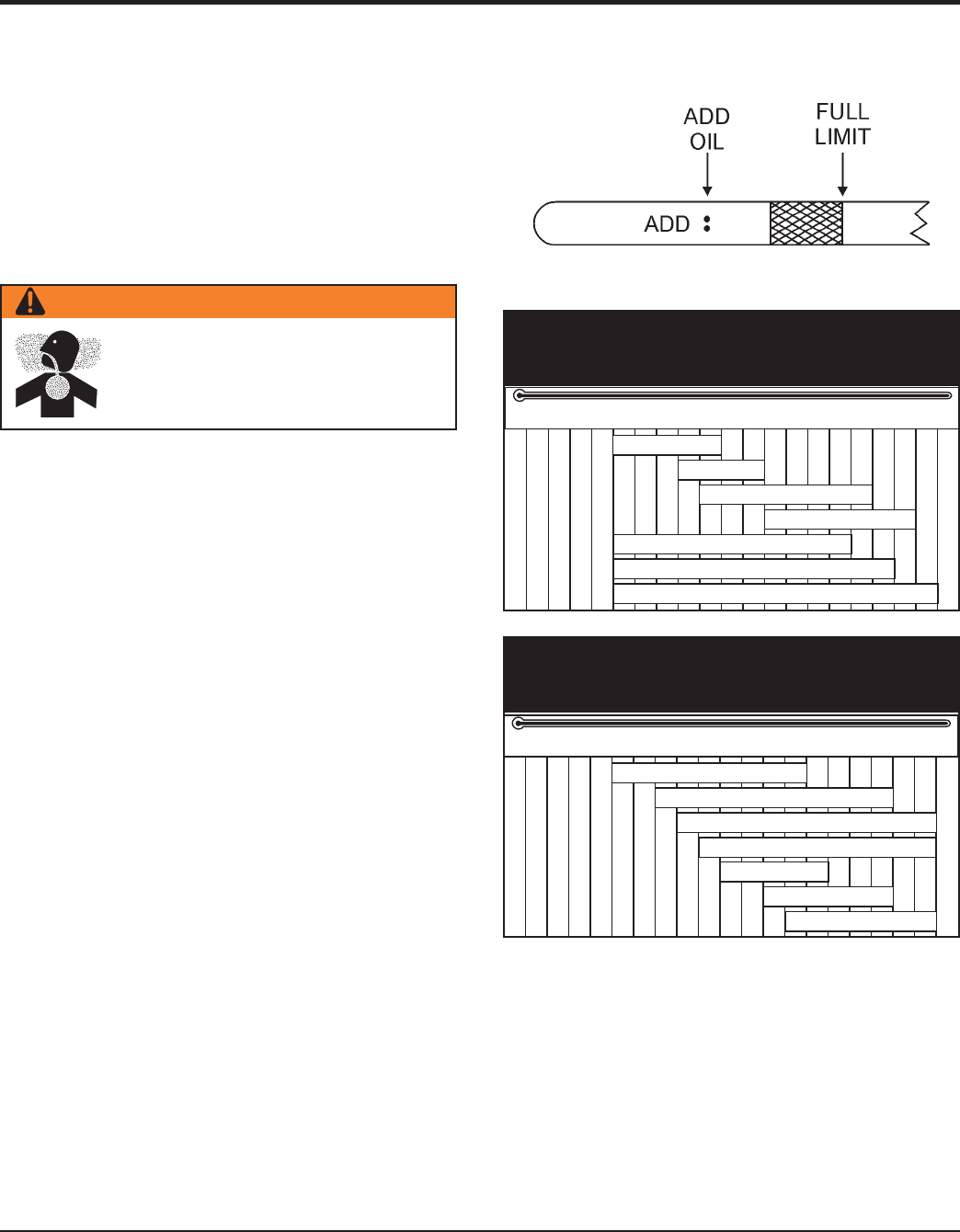

Insert and remove the dipstick from its holder. Check 2.

the oil level shown on the dipstick.

If the oil level is low, add oil through the oil fi ller hole. DO 3.

NOT overfi ll. Fill to the normal operating level as shown

on the dipstick. Verify that the oil level is maintained

WARNING

Ensure adequate ventilation when

operating the light tower in enclosed areas.

The engine exhaust contains noxious

elements.

between the two notches as shown in Figure 6. Always

fi ll with recommended type oil as listed in Tables 4 and

5. See Table 2 for engine oil capacity.

Oil DipstickFigure 6.

Other types of motor oils may be substituted if they meet

the following requirements:

API Service Classifi cation CH-4

API Service Classifi cation CG-4

API Service Classifi cation CF-4

ACEA Specifi cation E3

ACEA Specifi cation E2

Recommended Motor OilTable 4.

(Deutz Engines)

-40 -35 -30 -25 -20 -15

-10

-5 0 5 10 15 20 25 30 35 40 45 50

-40 -31 -22 -13 -4 5

14

23 32 41 50 59 68 77 86 95 104 113 122

SAE 10W

SAE 20W

SAE 30

SAE 10W-30

SAE 10W-40

SAE 10W-60

SAE 40

°C

°F

Recommended Motor OilTable 5.

(Perkins Engines)

-40 -35 -30 -25 -20 -15

-10

-5 0 5 10 15 20 25 30 35 40 45 50

-40 -31 -22 -13 -4 5

14

23 32 41 50 59 68 77 86 95 104 113 122

SAE 5W-20

SAE 10W-30

SAE 15W-40

SAE 20

SAE 30

SAE 40

SAE 20W-50

°C

°F