WM45H/E PLASTER MORTAR MIXER • OPERATION AND PARTS MANUAL — REV. #0 (09/27/12) — PAGE 23

Main Gear and Drive Pinion Alignment

3. Disconnect the spark plug wire. In addition make sure

the clutch engagement lever is dis-engaged to relieve

V-belt tension.

4. The countershaft and drive pinion are mounted on a

slotted base. To align drive pinion with main gear, loosen

the pillow block mounting bolts and move them until

the necessary alignment has been made. Remember

gears must be paralleled aligned not skewed.

5. Using your hand, slightly move (rock) the drive pulley

back and forth to determine the amount of backlash.

Insert feeler gauge between gears to determine

backlash distance. Backlash should range between

0.007- 0.012 inches (Figure 27).

Figure 27. Drive Pinion and

Main Gear (Backlash)

Inspect Tooth Contact Between Main Gear and

Drive Pinion

1. Coat 3 or 4 teeth at 3 different positions on the main

gear with yellow paint.

2. Rotate the drive pulley in both directions.

3. Inspect the tooth pattern.

4. If gear teeth are not contacting properly (Figure 28),

adjust pillow block to correct the problem.

Figure 28. Gear Teeth Alignment

HEAL

CONTACT

TOE

CONTACT

FACE

CONTACT

FLANK

CONTACT

PROPER

CONTACT

MAINTENANCE (MIXER)

Gear Lubrication

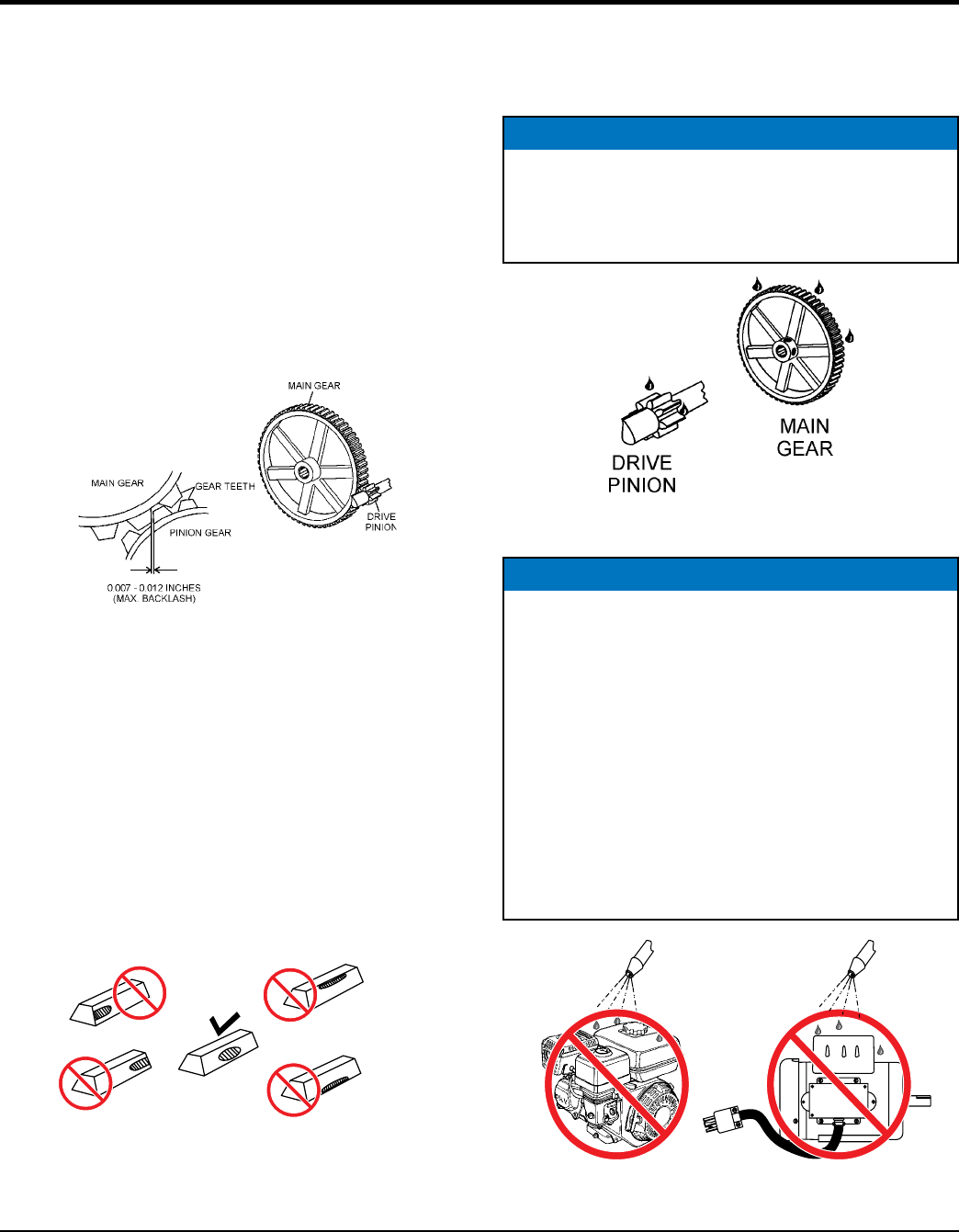

The surface of the pinion and main gear (Figure 29) should

be very lightly greased.

Figure 29. Pinion and Bull Gear Lubrication

Figure 30. No Spraying of Water

NOTICE

Re Grease main and pinion gears every 250 hours of

operation. IMPORTANT! avoid over-greasing. Excess

grease will accumulate contaminates and cause

premature wear.

NOTICE

Mixer Cleaning

ALWAYS disconnect the spark plug wire before

cleaning inside of mixing drum.

NEVER pour or spray water (Figure 30) over engine

or electric motor.

For consistent performance, long life and high quality

mixing, thoroughly clean the mixer inside and out at

the end of each day’s operation. To prevent lumps of

dried mortar from forming and contamination of future

batches, do not allow a buildup of materials to form on

the blades or anywhere inside the drum.

SINGLE

PHASE

115/230 VAC

ELECTRIC

MOTOR

ON

OFF

230

115

1.0 HP