Chapter 4 Maintenance Series 830/840/860 Instruction Manual

4-4 IM-83/84/86-H

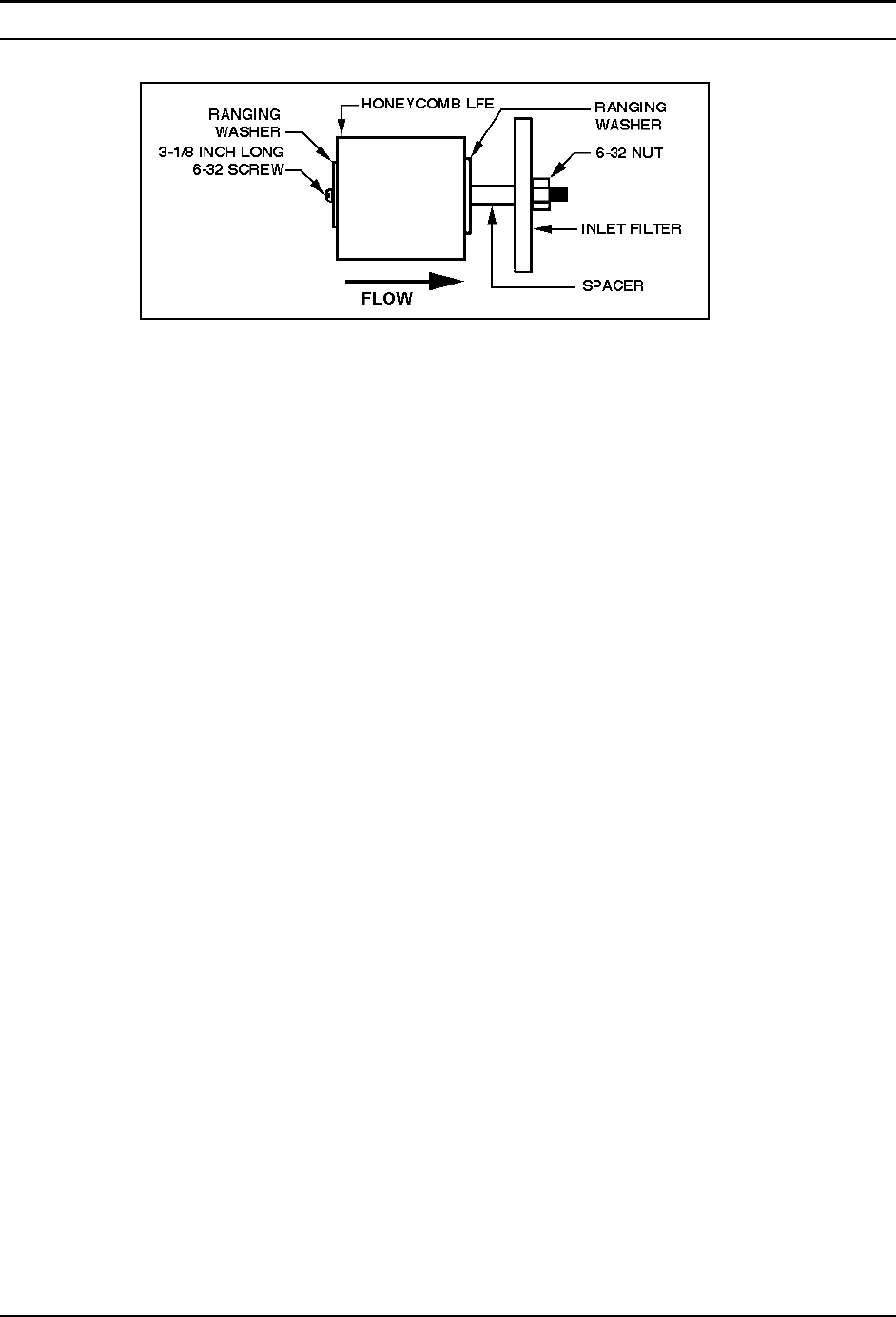

Figure 4-3. High Flow Transducer LFE Cleaning

High Flow Transducers:

The high flow LFE is similar to the honeycomb element used in the

medium flow body but larger in diameter. The high flow body con-

sists of four parts: inlet tube, inlet cap, main flow body and end cap.

The inlet tube is only removed to inspect and replace the sealing O-

ring between the inlet tube and inlet cap. To access the components:

1. Remove the unit from the system.

2. To remove the inlet screen, remove the four 1/4-28 socket head cap

screws on the inlet side of the flow body and separate the inlet cap

from the main flow body.

3. Inspect the inlet screen for damage and corrosion and replace if neces-

sary. Light to medium particulate contamination can be cleaned by back

washing with a suitable solvent. Air dry thoroughly.

4. Inspect the sealing O-ring for damage and replace if necessary.

The inlet screen is mounted with the fine mesh side facing the inlet.

5. To remove the LFE loosen and remove the four threaded rods hold-

ing the end cap to the main flow body. Separate the end cap from the

main flow body and remove the LFE assembly. The LFE assembly

consists of: 6-32 x 31/8 inch long screw, a #6 washer, two ranging

washers, honeycomb LFE, spacer, inlet filter and 6-32 nut.

6. Inspect the honeycomb element for damage and replace if necessary.

Replacement of the LFE or inlet screen requires transducer re-

calibration.

`

7. Re-assemble components. When the transducer is re-installed in the system,

leak test the connection.

8. Check transducer calibration.