GP Series Portable Chillers Chapter 7: Appendix 60 of 73

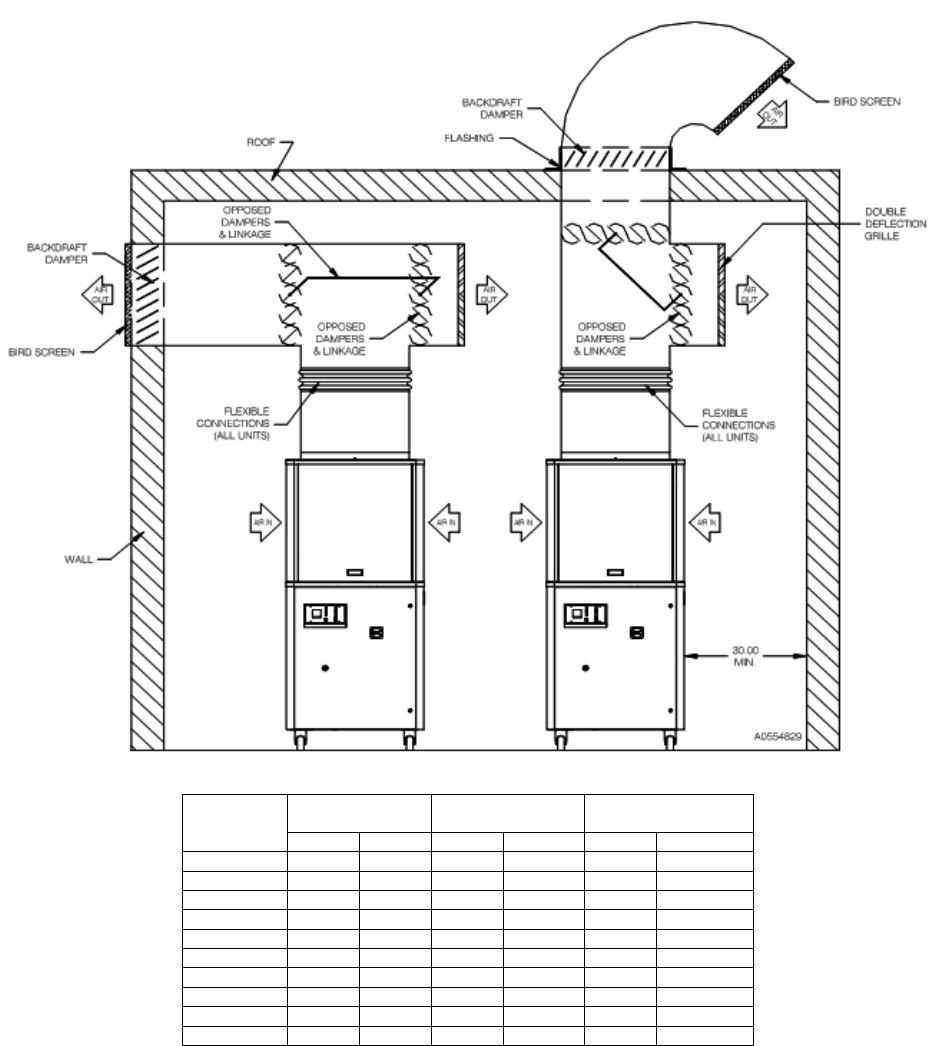

7-6 Typical Ductwork for Air-Cooled Chillers

Fan

60 Hz Discharge

air volume

50 Hz Discharge air

volume

Model

HP kW CFM m

3

/min CFM m

3

/min

GPAC-20 0.5 0.4 4230 120 3525 100

GPAC-30 1.0 0.7 6343 180 5286 150

GPAC-40 1.0 0.7 8458 240 7048 200

GPAC-50 2.0 1.5 12687 360 10573 300

GPAC-70 (2) 1.0 (2) 0.7 16916 479 14097 399

GPAC-90 (2) 2.0 (2) 1.4 25374 718 21145 598

GPAC-105 (2) 2.0 (2) 1.4 25374 718 21145 598

GPAC-140 (3) 2.0 (3) 1.4 38061 1077 31718 898

GPAC-175 (3) 2.0 (3) 1.4 38061 1077 31718 898

GPAC-210 (4) 2.0 (4) 1.4 50748 1436 42290 1197

When locating your air-cooled portable chiller and designing its ductwork, note any potential high

temperature conditions when discharging into your building and any negative pressures with the building

when discharging air outside.

Notes: • Customer use of ductwork requires the high pressure fan option. • Allow 30” (77 cm) minimum

clearance around the chiller footprint to facilitate free passage of cooling air and service accessibility •

Size the ductwork for maximum capacity • Support ductwork from the building structure, not off of the