2.3. Com pressed-air sup ply (only with com pressed-air valves)

For op er at ing the con trol valves, a

com pressed-air sup ply is nec es -

sary.

Check com pressed-air pip ing for

cor rect in stal la tion and as sem bly.

Check fit tings, length and qual ity of

the hose con nec tions for agree -

ment with re quire ments.

The op er at ing pres sure is 5-6 bar

(72.52-87.02 PSI) (sys tem

overpressure).

Check the com pressed-air sup -

plied by the plant’s sup ply net work.

Ad just com pressed-air pres sure to

5-6 bar (72.52-87.02 PSI) (sys tem overpressure).

Com pressed air must be dewatered and oiled.

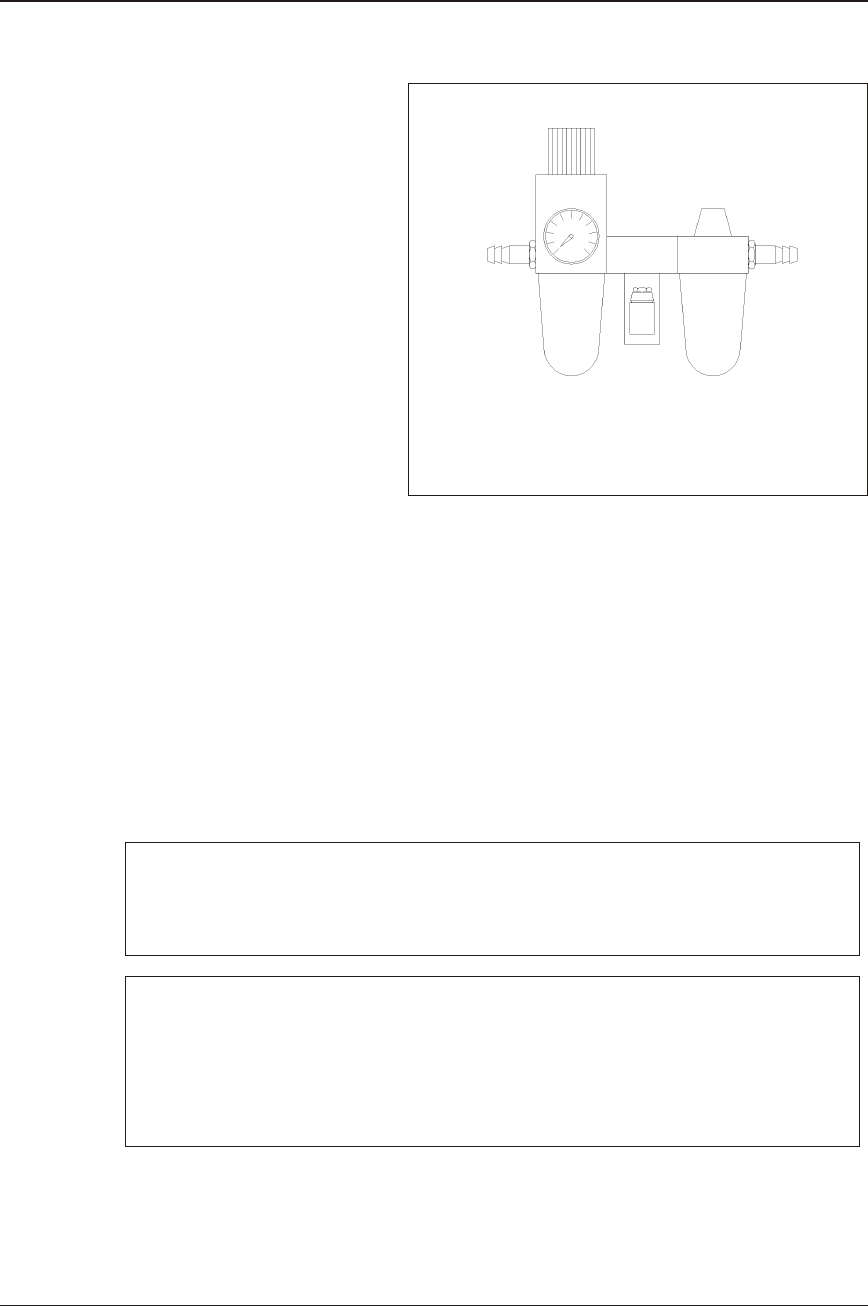

In stall a main te nance unit (pres sure re ducer with wa ter sep a ra tor and oiler) if re -

quired.

Con nect the unit to the plant’s sup ply net work by means of a hose.

L

Depressurize com pressed-air sup ply lines which must be

opened.

F

Com pressed air must be dewatered and oiled.

Ad just pres sure to a max. value of 6 bar (87.02 PSI) (sys tem

overpressure).

016-3MS

SSK-3

In stal la tion in struc tions 12

Main te nance unit